Customized products

All kinds of slip on flange

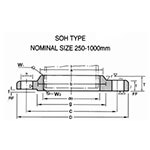

SPECIFICATIONS

All kinds of slip on flange

The flange is the part of the shaft and the shaft that is connected to each other for the connection between the ends of the pipe; it is also used for the flange on the inlet and outlet of the device for the connection between the two devices.Flange connection refers to the detachable connection of flanges,gasketsand bolts as a set of combined sealing structures.

There are holes in the flange, and the bolts make the two flanges tightly connected. The flanges are sealed with gaskets.

What is Slip On Flange?

Slip on flange, as the meaning of the name,is a flange slipping on the pipe or fitting when connection. The pipe should insert the flange inner bore, and leave a bit distance from the face of the flange to make sure it will not affect the sealing of two flanges.

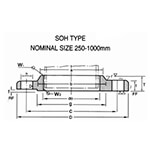

Some kinds of slip on flange:

The Welding of A Slip On Flange:

When welding a slip on flange to a pipe,the welder should make some temporary tack weld to fasten the alignment between the pipe and flange,then the welder carry out the fillet weld around the end of pipe to the inside of the slip on flange,and another fillet weld also should be done around the back end of the flange and the outside of pipe.The two fillet welding can make sure the quality for the joint between pipe and flange.Of course,it will also increase the welding cost.

slip on flange has a different sealing face:

1. flat face flange also be called FF flange

2. raised face flange also be called RF flange

The two sealing face flange using in the different standard. according to different technical date using in the different pipeline or pipe fittings.

Metleader pipeline has more than 26 years Production experience,if you have any need welcome you contact us any time.