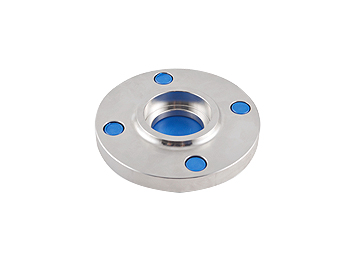

Plate Flange /Slip on flange

DIN Carbon Steel Slip on Flange

SPECIFICATIONS

Material:Carbon

Manufacturing Way: Forging

Surface Painting: Black, Anti-Rust Oil, Varnish

Packaging: Plywood Pallet, Case, Carton

The full name of the DIN is Deutsches Institut für Normung e.V., is commonly used in some European countries.

DIN Carbon Steel Slip on Flange /SO Flange has a variety of specifications, such as PN6, PN10, PN16, PN25, PN40, PN64. As made obvious by their name, these pipe flanges slip over the pipe. They're manufactured with an inside diameter that is slightly bigger than the pipe's outside diameter. These attachments are connected to the pipe via fillet weld at the top and bottom of the flange.

Advantages of slip on flanges:

a.Low cost installation.

b. Less time needed to spent on ensuring the accuracy of the cut pipe.

c. They are somewhat easier to align.

d. The slip-on flanges have low hub because the pipe slips into the flange before welding.

e. The flange is welded both inside and outside to provide sufficient strength.

f. They prevent leakage.

We also provide many other Flanges of different shapes and materials.

For example: Stainless steel Slip on Flange, DIN Carbon Steel Welding Neck Flange, etc.

| Pipe | Flange | Screws | Weight of a flange (7,85 Kg/dm3) |

||||||||

| Rated Diameter |

d1 | d5 | D | b | c | k | Number | Thread | d2 | Kg | |

| ISO Series 1 | DIN Series 2 | ||||||||||

| 15 | - | 20 | 21 | 80 | 12 | 5 | 55 | 4 | M 10 | 11 | 0,41 |

| 21,3 | - | 22 | |||||||||

| 20 | - | 25 | 26 | 90 | 14 | 5 | 65 | 4 | M 10 | 11 | 0,6 |

| 26,9 | - | 27,6 | |||||||||

| 25 | - | 30 | 31 | 100 | 14 | 5 | 75 | 4 | M 10 | 11 | 0,74 |

| 33,7 | - | 34,4 | |||||||||

| 32 | - | 38 | 39 | 120 | 16 | 5 | 90 | 4 | M 12 | 14 | 1,19 |

| 42,4 | - | 43,1 | |||||||||

| 40 | - | 44,5 | 45,5 | 130 | 16 | 5 | 100 | 4 | M 12 | 14 | 1,39 |

| 48,3 | - | 49 | |||||||||

| 50 | - | 57 | 58,1 | 140 | 16 | 6 | 110 | 4 | M 12 | 14 | 1,53 |

| 60,3 | - | 61,1 | |||||||||

| 65 | 76,1 | - | 77,1 | 160 | 16 | 6 | 130 | 4 | M 12 | 14 | 1,89 |

| 80 | 88,9 | - | 90,3 | 190 | 18 | 7 | 150 | 4 | M 16 | 18 | 2,98 |

| 100 | - | 108 | 109,6 | 210 | 18 | 7 | 170 | 4 | M 16 | 18 | 3,46 |

| 114,3 | - | 115,9 | |||||||||

| 125 | - | 133 | 134,8 | 240 | 20 | 7 | 200 | 8 | M 16 | 18 | 4,6 |

| 139,7 | - | 141,6 | |||||||||

| 150 | - | 159 | 161,1 | 265 | 20 | 7 | 225 | 8 | M 16 | 18 | 5,22 |

| 168,3 | - | 170,5 | |||||||||

| 200 | 219,1 | - | 221,8 | 320 | 22 | 7 | 280 | 8 | M 16 | 18 | 7,15 |

| 250 | - | 267 | 270,2 | 375 | 24 | 7 | 335 | 12 | M 16 | 18 | 9,61 |

| 273 | - | 276,2 | |||||||||

| 300 | 323,9 | - | 327,6 | 440 | 24 | 7 | 395 | 12 | M 20 | 22 | 12,6 |

| 350 | 355,6 | - | 359,7 | 490 | 26 | 7 | 445 | 12 | M 20 | 22 | 15,6 |

| - | 368 | 372,2 | |||||||||

| 400 | 406,4 | - | 411 | 540 | 28 | 7 | 495 | 16 | M 20 | 22 | 18,4 |

| - | 419 | 423,7 | |||||||||

| (450)* | 457 | - | 462,5 | 595 | 30 | 7 | 550 | 16 | M 20 | 22 | 21,4 |

| 500 | 508 | - | 531,6 | 645 | 30 | 7 | 600 | 20 | M 20 | 22 | 24,6 |