What's the advantage of using slip on flanges?

Slip on flange is one type of flat welding flanges. Flat welding only use to weld the outer layer, don’t weld the inner layer. Generally flat welding flange would be used in medium and low pressure pipelines, nominal pressure of the pipeline is less than 2.5mpa. There are four types of sealing surface of flat welding flanges, flat face, RF(raised face), FM/M, and TG(tongue and groove face). The flat face is the most used widely and the price is the cheapest. Slip on flange as one kind of flat welding flange with a short hub.

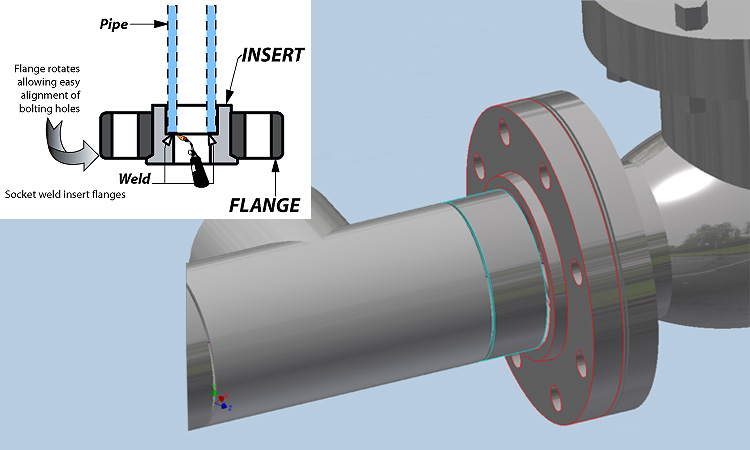

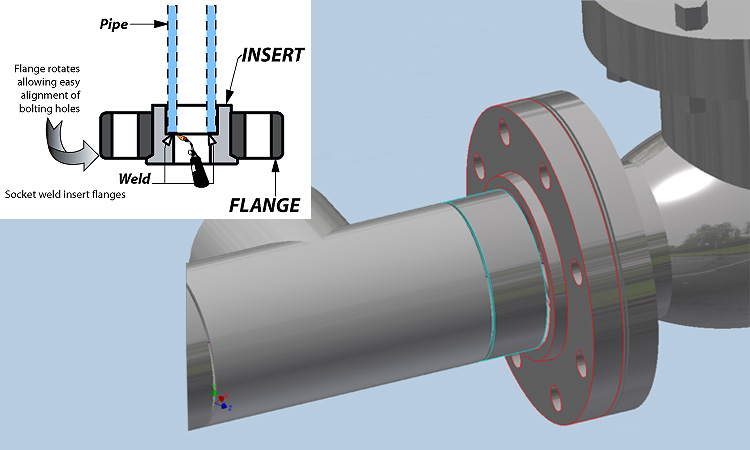

Carbon steel slip on flanges or SO flanges are usually cheaper than welding neck flanges that is just why our customers commonly to choose slip on flange. As the name of slip on flange expressed, these pipe flanges can slid on the pipes. Their inside diameter is slightly larger than the outside diameter of the pipe. These attachments are connected to the pipe by corner welding at the top and bottom of the flange.

However, customers should be known that the additional welding cost of installing the required two corner welds properly deduct the initial cost savings. In addition, the using life of welding neck flange is higher than slip on flange.

Slip on flanges are all slightly larger than the O.D. of the pipeline. Because of their low initial cost, they are more popular than welding neck flange for many users, but due to the additional welding cost involved, final installation costs may not be much lower than the welding neck flange.

However, slip on flange still have many special advantages for using.

1.Low cost of installation.

2.Saving time on ensuring the accuracy of cutting pipes.

3.Slip on flange is easier to align when welding.

4.The slip on flanges have low error because the pipe have been slided into the flange before welding.

5.The flange is welded both inside and outside to provide sufficient strength.

6.The leakproofness is good.

Carbon steel slip on flanges or SO flanges are usually cheaper than welding neck flanges that is just why our customers commonly to choose slip on flange. As the name of slip on flange expressed, these pipe flanges can slid on the pipes. Their inside diameter is slightly larger than the outside diameter of the pipe. These attachments are connected to the pipe by corner welding at the top and bottom of the flange.

However, customers should be known that the additional welding cost of installing the required two corner welds properly deduct the initial cost savings. In addition, the using life of welding neck flange is higher than slip on flange.

Slip on flanges are all slightly larger than the O.D. of the pipeline. Because of their low initial cost, they are more popular than welding neck flange for many users, but due to the additional welding cost involved, final installation costs may not be much lower than the welding neck flange.

However, slip on flange still have many special advantages for using.

1.Low cost of installation.

2.Saving time on ensuring the accuracy of cutting pipes.

3.Slip on flange is easier to align when welding.

4.The slip on flanges have low error because the pipe have been slided into the flange before welding.

5.The flange is welded both inside and outside to provide sufficient strength.

6.The leakproofness is good.