Disadvantages and advantages of different flange connection (I)

What is flange connection?Flange connection is a removable joint that fixes two pipes, fittings or equipment ononeflange, then adds flange gaskets between the two flanges, and finally tightens the two flanges tightly by bolts.

The function of flange connection

Flange fitting is a kind of component widely used in engineering design. It is an indispensablepartin piping design, pipe fittings and valves, and also a necessary component in equipment and equipment components (such as manhole, mirror level gauge, etc.). In addition, flange fittings are often used in other specialties such as industrial furnaces, thermal engineering, water supply and drainage, heating and ventilation, automatic control, etc.

The types of flange connections

The flange connections include plate flange connection, slip on flange connection, weld neck flange connect, blind flange connection, socket flange connection, thread flange connection etc. and comparison between different kins of flanges.

The standards of flange connections

The carried standards of flange connections refer to GB series, ASME B16.5, JIS series, BS4504, DIN series, GOST series and EN1092 etc. There are two main international standards for pipe flanges, namely the European pipe flange system represented by DIN (including the former Soviet Union) and the American pipe flange system represented by ANSI pipe flange in the United States.

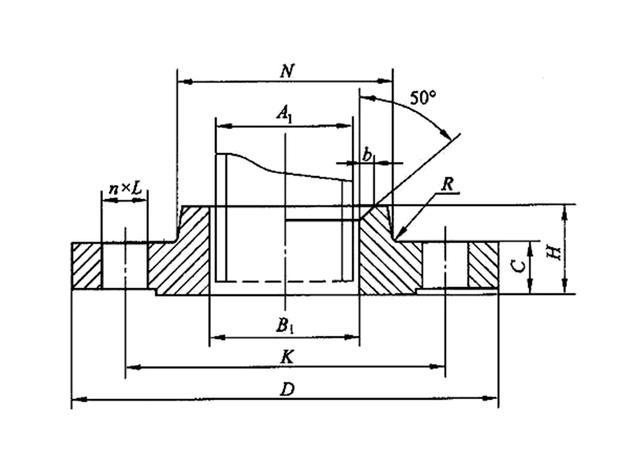

Plate welded flange connection

Plate welded flange is suitable for steel pipe connections with nominal pressure not exceeding 2.5 MPa. Plate welded flange sealing face can be made into flat, male-female and tongue and groove types.Flat welded flange is the most widely used in mild medium conditions, such as low-pressure non-purified compressed air and low-pressure circulating water.

Advantages: easy to obtain materials, simple to manufacture, low cost, wide use

Disadvantages: poor rigidity, so it should not be used in chemical process piping systems with requirements of supply and demand, flammability, explosion and high vacuum, and in situations of high and extreme hazards.

The type of sealing surfacehasplane and protruding surface.

Slip on flange connection

Slip on flange belongs to the national standard flange system. It is one of the GB flange (also known as GB flange), is one of the commonly used flange equipment or pipelines.

Advantages: field installation is more convenient, can omit the welding seam patted kneading process

Disadvantages: the neck heightofslip on flange connection is low, which improves the rigidity and bearing capacity of the flange. Compared with welding neck flanges, welding workload, high consumption of welding rod, can not withstand high temperature and pressure and repeated bending and temperature fluctuations.

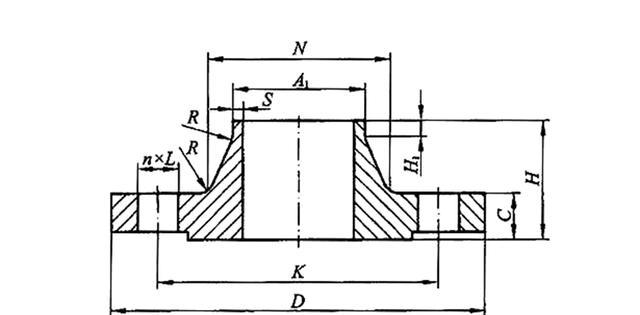

Welding neck flange connection

Welding neck flange is not easy to deformation, good sealing, wide application, have corresponding rigid and elastic demand and reasonable butt thinning transition, joint good distance away from the joint face the faying surface from welding deformation temperature,ittake more complex syndromes beep form structure, suitable for pressure or temperature fluctuations of pipeline or high temperature, high pressure and low temperature pipes, commonly used in PN is greater than 2.5 MPa pipe and valve connection;It is also used for conveying expensive, flammable and explosive media.

Sealing surface of welding flange with neck includes: face (RF), concave (FM), convex (M), tenon (T), groove (G) and full plane (FF).

Advantages: connection is not easy to deformation, sealing effect is good, widely used, suitable for temperature or pressure fluctuations of the pipe or high temperature,high pressure andlow temperature pipe, also used for conveying expensive medium, flammable and explosive medium, toxic gas pipe

Disadvantages: large size,heavy weight, expensive, difficult to install and locate.Therefore, it is easier to bump in transit.