Comparison between different kinds of flanges

Flanges are widely used in piping networks and can be disassembled to connect various piping components, such as valves, special items and connections to equipment. They are usually made from forging processes. Only in a few cases can it be made of plates. In ASME B16.5, blind Flanges can only be manufactured using weldable high-quality plates and the flange is reduced.Material of flanges:

1. A105: Standard specification for carbon steel forgings for piping.

2. A181: Standard specification for carbon steel forgings for general purpose pipelines.

3. A182: Standard specification for forged or rolled alloys and stainless steel pipe flange, forging fittings, and valves and parts for high temperature services.

4. A350: Standard specification for carbon and low alloy steel forgings, requiring notch toughness testing of piping components.

Types of Flanges:

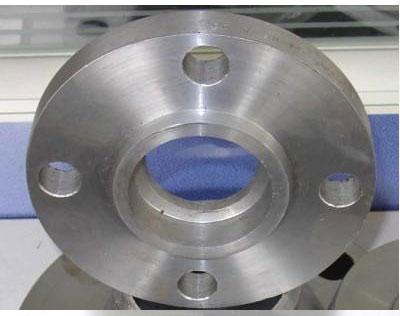

Slip on Flanges

Socket Weld Flanges

Threaded Flanges

Welding Neck Flanges

Reducing Flanges

Blind Flanges

Lap Joint Flanges

Features of slip on flanges:

1. The slip on the flange is usually forged with a hub.

2. When they are produced by plates, they have no hubs.

3. The slip on flange is more economical than the welding neck flange.

4. They are used for non-critical applications above 2 "NPD.

5. The slip on flange are welded internally and externally to the pipe.

Features of Socket weld Flange:

1. Socket weld flange is used for socket welding small diameter pipe.

2. They are welded only outside the pipe.

3. There is a small pocket behind the pipe to accommodate the thermal expansion of the pipe, which can cause the fluid to stagnate and corrode if the fluid is highly corrosive.

4. The socket weld flange shall specify the thickness of the connecting pipe to ensure the appropriate pore size.

Features of Thread flanges:

1. Threaded flange is used in small-caliber threaded pipes.

2. They are also used in locations where welding is not allowed.

3. Threaded flanges are used at temperatures ranging from 25 ° C to 450 degrees Celsius.

4. Depending on the requirements of the piping specification, the thread can be the NPT (nominal pipe thread) or BSPT (British Standard pipe thread).

Features of welding neck flanges:

1. Welding neck flange and pipe are butt welded together.

2. Since all weld lines required radiography in key service, welding neck flanges are mainly used in such locations.

3. The thickness of the welding neck flange, which is usually the same thickness as the pipe of the same size, needs to be specified at the time of purchase.

4. Welding neck flanges are more expensive and are used in high temperature, flammable, toxic and other services.

Features of lap joint flanges:

1. The lap joint flange is used together with the end of the short tube, and the end of the short tube is welded with the pipe butt.

2. It is used where pipes are of higher grade or special materials.

3. Lap joint flanges are mainly carbon steel.

4. The inner diameter of the splice flange is machined to accommodate the radius of the short end.

Features of blinds:

The blind flange is used to close the end of the pipe and fasten it to another flange. In a few places, the purchase of blind flanges with threaded holes is used for instrumentation or drainage connections.

Features of blind flanges:

The reduced flange used to connect pipes of different diameters without using a reducer. The size and thickness of the decompression flange shall be a pipe of a larger diameter, but the inner diameter shall be suitable for pipes of smaller diameters.

Previous:100% carbon steel pipefittings delivery rate

Next:How to establish relationship exporting flanges?

Next:How to establish relationship exporting flanges?