Line Pipe

Home > Products > Steel Pipes > Line Pipe

How To Choose Line Pipe

SPECIFICATIONS

Line pipe is a type of steel pipe which is generally used for transporting materials through pipelines across the country. Line pipe can be used to transport petroleum, natural gas, oil, and water. The line pipes have different of diameters, ranging from 2 inches to 48 inches. For example, in most cases, the main pipeline carrying natural gas will require lines about 16 to 48 inches in diameter. Smaller lines that carry gas to and from main lines can be made up of pipes 6 to 16 inches in diameter.

How to choose line pipe |

|

| Material Standard | ASTM, ASME and API |

| Grades | API 5L Gr. X42/X46/X52/X56/X60/X65/X70/X80and higher. PSL-1/PSL-2. ASTM A106 Gr. B/C. ASTM A53 Gr. B |

| Steel Pipe Dimensions | 1/2 inch to 12 inch, 14 inch, 16 inch, 18 inch, 20 inch, and 24 inch for seamless. |

| Wall thickness | SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS to SCH 160. |

| Length Range | 20 FT (6 meter), 40FT (12 meter)or customized |

| Ends Type | Beveled ends, Plain ends |

| End Protection | plastic Caps or iron Caps |

| Surface Coatings | Natural, Varnished, Black painting, 3PP, FBE and 3PE, Cladding and Lined etc. |

What is line pipe?

Line pipe is a kind of pipe that is made of high strength carbon steel. It is usually manufactured according to metallurgical specifications set by the American Petroleum Institute (API). There are two grade API 5L PSL1 and PSL2. The technical requests of PSL2 are higher than PSL1, some pipelines used for special conditions need to adopt PSL2. Line pipes are mainly used for the transportation of oil, natural gas and other fuels. Common line pipes are seamless pipe and welded pipe, and their pipe ends have flat ends, threaded ends and socket ends.

The line pipes have different of diameters, ranging from 2 inches to 48 inches. For example, in most cases, the main pipeline carrying natural gas will require lines about 16 to 48 inches in diameter. Smaller lines that carry gas to and from main lines can be made up of pipes 6 to 16 inches in diameter.

The line pipes have different of diameters, ranging from 2 inches to 48 inches. For example, in most cases, the main pipeline carrying natural gas will require lines about 16 to 48 inches in diameter. Smaller lines that carry gas to and from main lines can be made up of pipes 6 to 16 inches in diameter.

The classification of the line pipe

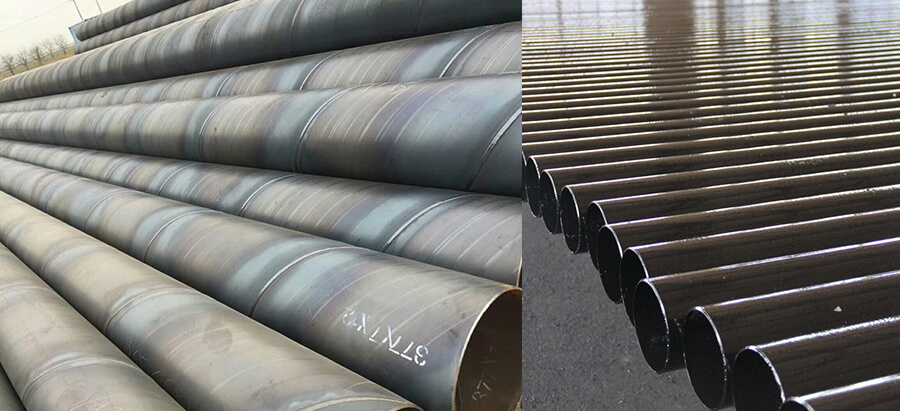

There are two types of line pipe, one is welded pipe and the other is seamless pipe. Both have different uses.

Seamless pipe: Seamless steel pipe seamless refers to the pipe production is made of steel ingot or solid tube billet by perforation, and then made of hot rolling, cold rolling or cold drawing, there is no binding gap in the inner wall of the pipe. It has a hollow cross section, a large number of used for conveying fluid pipelines, such as conveying oil, natural gas, gas, water and some solid materials pipelines. Compared with solid steel such as round steel, steel pipe has the same bending and torsional strength and is lighter in weight. It is a kind of economical cross section steel. Generally, it can be divided into circular and special-shaped according to the empty section in the middle. When the circumference is unchanged, the circular conveying liquid is more, and the pressure inside the tube is more uniform. So in application, it must be based on its characteristics and used to the right place to play the maximum utility.

Welded pipe: Welded steel pipe refers to steel belt or steel plate bending deformation into a round, square and other shapes after welding, surface joints of the steel pipe. Welding steel pipe production process is simple, high production efficiency, variety specifications, less equipment, but the general strength is lower than seamless steel pipe. Since the 1930s, with the rapid development of high quality strip continuous rolling production and the progress of welding and inspection technology, the weld quality has been continuously improved, and the varieties and specifications of welded steel tubes have increased day by day, and the seamless steel tubes have been replaced in more and more fields. Welded steel pipe is divided into straight seam welded pipe and spiral welded pipe according to the form of weld.

Comparison for two Line Pipe

Seamless pipe: The base material for the production of seamless pipes is the pipe blank, which has square and round bar materials, which are processed by perforation and other processing processes, or hot rolled or cold drawn into tubes. The main advantages of seamless pipes are as follows: Not having a heat-affected zone, better corrosion resistance, more homogeneous grain structure, no extra weld integrity testing, no problem with weld-seam orientation and no need for pressure de-rating.

Welded pipe: welded pipes is steel plate or steel belt, and the surface is a pipe with welding ribs after cutting, bending, welding and other processes. The main advantages of welded pipes are their lower inherent cost, narrower tolerances for wall thickness, concentricity (OD/ID) and internal surfaces that can be checked prior to manufacture.

Welded pipe: welded pipes is steel plate or steel belt, and the surface is a pipe with welding ribs after cutting, bending, welding and other processes. The main advantages of welded pipes are their lower inherent cost, narrower tolerances for wall thickness, concentricity (OD/ID) and internal surfaces that can be checked prior to manufacture.

Why choose Metleader to buy seamless line pipe?

As a leading supplier of line pipe Metleader has rich experience for supplying this kind of steel pipe. We exported the line pipes to world famous oil company such as DNO, Kar, Total, SINOPEC, PetroChina, etc. Our company have been passed several certificates including ISO9001: 2008, ISO14001, OHSAS18001, CE certificate, one member of supplier system of Sinopec, and CNPC. We welcome your inquiry timely sales@metleader.com .