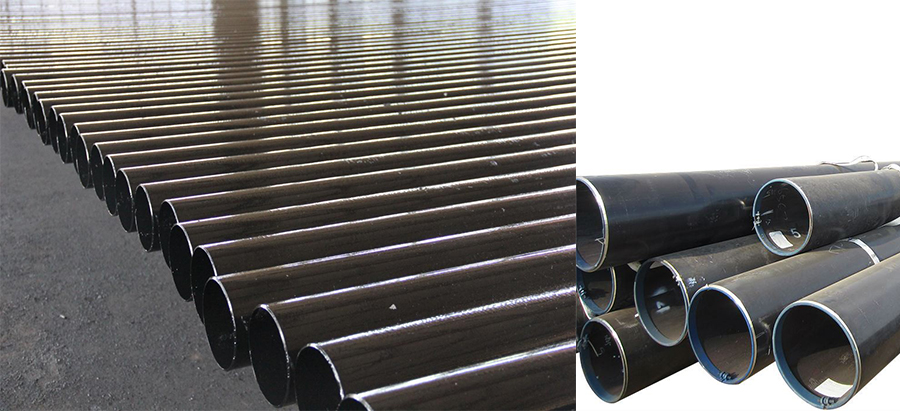

Line Pipe

Home > Products > Steel Pipes > Line Pipe

High strength carbon steel pipe

SPECIFICATIONS

Carbon steel pipes for carbon content less than 0.25%, due to its low strength, low hardness and soft, it is also known as mild steel. It includes most common carbon structural steel and a part of high quality carbon structural steel. The steel pipe has a hollow section and is widely used in machinery, architecture, oil, natural gas, central station, boiler, power station, ship, chemical, environmental protection, food and other industries.

| High strength carbon steel pipe | |

| Material Standard | ASTM, ASME and API |

| High Temperature Carbon Steel Pipe | ASTM A106 Gr. B/C, API 5L Gr. B, ASTM A53 Gr. B |

| Low Temperature Carbon Steel Pipe | ASTM A333 Gr. 3/6 |

| High Yield Carbon Steel Pipe | API 5L Gr. X42/X46/X52/X56/X60/X65/X70/X80and higher. PSL-1/PSL-2 |

| Form | Round, Square, Rectangular Etc |

| Outer Diameter | 20MM~508MM |

| Wall thickness | SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160 |

| Length Range | 20 FT (6 meter), 40FT (12 meter)or customized |

| Ends Type | Beveled ends, Plain ends |

| End Protection | plastic Caps or iron Caps |

| Surface Coatings | Natural, Varnished, Black painting, FBE and 3PE, Cladding and Lined etc. |

What are carbon steel pipes?

Carbon steel pipes for carbon content less than 0.25%, due to its low strength, low hardness and soft, it is also known as mild steel. It includes most common carbon structural steel and a part of high quality carbon structural steel. The steel pipe has a hollow section and is widely used in machinery, architecture, oil, natural gas, central station, boiler, power station, ship, chemical, environmental protection, food and other industries.

Carbon steel pipes are made of ingot or solid round steel by perforation, and then hot rolled, cold rolled or cold drawn. Hot rolled carbon steel pipe is divided into general steel pipe, low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, petroleum cracking pipe, geological steel pipe and other steel pipe. Cold rolled (drawn) carbon steel pipe is divided into general steel pipe, low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, petroleum cracking pipe, other steel pipes, but also includes carbon thin wall steel pipe, alloy thin wall steel pipe, stainless steel pipe, special-shaped steel pipe. The outer diameter of hot rolled seamless pipe is generally greater than 32mm, the wall thickness is 2.5-75mm, the outer diameter of cold rolled seamless steel pipe can be up to 6mm, the wall thickness can be up to 0.25mm, the outer diameter of thin-walled pipe can be up to 5mm, the wall thickness is less than 0.25mm, the cold rolling is higher than the hot rolling size accuracy.

Generally used carbon steel pipe to ensure the strength and flattening test. Hot rolled steel pipes are delivered in hot rolled or heat treated state; Cold rolling is delivered in heat treatment condition.

Carbon steel pipes are made of ingot or solid round steel by perforation, and then hot rolled, cold rolled or cold drawn. Hot rolled carbon steel pipe is divided into general steel pipe, low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, petroleum cracking pipe, geological steel pipe and other steel pipe. Cold rolled (drawn) carbon steel pipe is divided into general steel pipe, low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, petroleum cracking pipe, other steel pipes, but also includes carbon thin wall steel pipe, alloy thin wall steel pipe, stainless steel pipe, special-shaped steel pipe. The outer diameter of hot rolled seamless pipe is generally greater than 32mm, the wall thickness is 2.5-75mm, the outer diameter of cold rolled seamless steel pipe can be up to 6mm, the wall thickness can be up to 0.25mm, the outer diameter of thin-walled pipe can be up to 5mm, the wall thickness is less than 0.25mm, the cold rolling is higher than the hot rolling size accuracy.

Generally used carbon steel pipe to ensure the strength and flattening test. Hot rolled steel pipes are delivered in hot rolled or heat treated state; Cold rolling is delivered in heat treatment condition.

Carbon steel pipe production process:

The raw material of the seamless rolling pipe is the round tube billet, the tube embryo must be cut by cutting machine and processed into a billet of about 1 meters in length, and sent to the furnace by conveyor belt. The billet is heated in a furnace, at a temperature of about 1200 degrees Celsius. The fuel is hydrogen or acetylene. Temperature control in furnace is a key problem. After the Tube billet is released, it is perforated by pressure piercing. Generally more common punch is the cone-shaped roller piercing machine, this type of piercing machine production efficiency, product quality, perforation expansion is large, can wear a variety of steel. After perforation, the round tube billet has been three-roll skew rolling, continuous rolling or extrusion. After extrusion to remove the tube sizing. The sizing machine rotates into the steel embryo punch through the conical bit at high speed, forming the steel pipe. The inner diameter of the pipe is determined by the diameter of the drill bit. After the steel tube is fixed, it enters the cooling tower and cools through the water spray, and the steel tube is straightened after cooling. After straightening, the steel tube is sent to the crack machine (or hydrostatic test) for internal flaw detection. If there are cracks inside the steel pipe, bubbles and other problems, will be detected. Steel pipe After quality inspection also through strict manual selection. After quality inspection, the paint is sprayed with the number, specifications, production batches and so on. And the crane is hoisted into the warehouse.

What are the applications of carbon steel pipe?

1. Pipes for mechanical industry. Such as aviation structure pipe (round pipe, ellipse pipe, flat ellipse pipe), automobile axle pipe, axle pipe, automobile tractor structure pipe, tractor oil cooler pipe, agricultural machinery with square pipe and rectangular pipe, transformer pipe and bearing pipe, etc.

2. Petroleum geology drilling pipe. Such as: oil drilling pipe, oil drill pipe (kelly and hexagonal drill pipe), drilling, oil piping, oil casing and various pipe joints, geological drilling pipe (core pipe, casing, active drill pipe, drilling, clamp and pin joints, etc.).

3. Pipes for the chemical industry. Such as: petroleum cracking pipe, chemical equipment heat exchanger and pipe, stainless acid-resistant pipe, fertilizer with high pressure pipe and transport chemical medium pipe, etc.

4. Pipework. Such as: water, gas pipe, steam pipe with seamless pipe, oil transmission pipe, oil and gas trunk pipe. Agricultural irrigation water faucet with pipe and sprinkler irrigation pipe.

5. Pipes for thermal equipment. Such as the general boiler with boiling water pipe, superheated steam pipe, locomotive boiler with heat pipe, smoke pipe, small smoke pipe, arch brick pipe and high temperature and high pressure boiler pipe.

6. Other departments use pipes. Such as: container pipe (high-pressure gas cylinder pipe and general container pipe), instrument pipe, hand watch case pipe, injection needle and medical instrument pipe, etc.

2. Petroleum geology drilling pipe. Such as: oil drilling pipe, oil drill pipe (kelly and hexagonal drill pipe), drilling, oil piping, oil casing and various pipe joints, geological drilling pipe (core pipe, casing, active drill pipe, drilling, clamp and pin joints, etc.).

3. Pipes for the chemical industry. Such as: petroleum cracking pipe, chemical equipment heat exchanger and pipe, stainless acid-resistant pipe, fertilizer with high pressure pipe and transport chemical medium pipe, etc.

4. Pipework. Such as: water, gas pipe, steam pipe with seamless pipe, oil transmission pipe, oil and gas trunk pipe. Agricultural irrigation water faucet with pipe and sprinkler irrigation pipe.

5. Pipes for thermal equipment. Such as the general boiler with boiling water pipe, superheated steam pipe, locomotive boiler with heat pipe, smoke pipe, small smoke pipe, arch brick pipe and high temperature and high pressure boiler pipe.

6. Other departments use pipes. Such as: container pipe (high-pressure gas cylinder pipe and general container pipe), instrument pipe, hand watch case pipe, injection needle and medical instrument pipe, etc.

Why choose us to buy carbon steel pipes ?

As a leading line pipe distributor, Metleader has been exporting line pipes with big quantity to many countries and areas. Our company have been passed several certificates including ISO9001: 2008, ISO14001, OHSAS18001, CE certificate, one member of supplier system of Sinopec, and CNPC. In situations like high pressure, temperature, and corrosion, our Carbon Steel Pipes are perfectly suitable. We will provide the best service to our customers. welcome your inquiry timely sales@metleader.com .

Our Advantages:

1. Quick Respond2. Reasonable Price

3. Abundant stock and prompt delivery

4. Flexible payment terms

5. Rich experiences in manufacturing and exporting

6. Excellent Quality