Line Pipe

Home > Products > Steel Pipes > Line Pipe

Seamless steel pipe--high quality steel

SPECIFICATIONS

A seamless steel pipe is a circular pipe having a hollow section and no seams around it. The seamless steel pipe is made of carbon steel, alloy steel, stainless steel ingot or solid tube blank, and then is made by hot rolling, cold rolling or cold drawing.

Seamless steel pipe--high quality steel |

|

| Material Standard | ASTM, ASME and API |

| Grades | API 5L Gr. X42/X46/X52/X56/X60/X65/X70/X80and higher. PSL-1/PSL-2. ASTM A106 Gr. B/C. ASTM A53 Gr. B |

| Steel Pipe Dimensions | 1/2 inch to 12 inch, 14 inch, 16 inch, 18 inch, 20 inch, and 24 inch for seamless. |

| Wall thickness | SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS to SCH 60. |

| Length Range | 20 FT (6 meter), 40FT (12 meter)or customized |

| Ends Type | Beveled ends, Plain ends |

| End Protection | plastic Caps or iron Caps |

| Surface Coatings | Natural, Varnished, Black painting, 3PP, FBE and 3PE, Cladding and Lined etc. |

| Technical Methods | Hot rolling, Cold rolling or Cold drawing. |

| Testing Methods | Pressure test,Flaw detection,Eddy current testing, Hydrostatic testing or Ultrasonicexamination and also with chemical and physical property inspection |

What is the seamless steel pipe?

A seamless steel pipe is a circular pipe having a hollow section and no seams around it. The seamless steel pipe is made of carbon steel, alloy steel, stainless steel ingot or solid tube blank, and then is made by hot rolling, cold rolling or cold drawing. The quality of end product – tubes, entirely depends upon both factors – quality control during the manufacturing process and the initial condition and quality of raw materials.

Hot-rolled steel pipe: Hot rolling is relative to cold rolling, which is rolled steel tube above the recrystallization temperature. Generally used for low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, petroleum cracking pipe, geological steel pipe and other steel pipe.

Cold-rolled steel pipe: Cold rolling is the steel tube rolled below the recrystallization temperature. Generally used for low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, petroleum cracking pipe, precision steel pipe, carbon thin-walled steel pipe, alloy thin-walled steel pipe, stainless steel thin-walled steel pipe, special-shaped steel pipe, etc.

Hot-rolled steel pipe: Hot rolling is relative to cold rolling, which is rolled steel tube above the recrystallization temperature. Generally used for low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, petroleum cracking pipe, geological steel pipe and other steel pipe.

Cold-rolled steel pipe: Cold rolling is the steel tube rolled below the recrystallization temperature. Generally used for low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, petroleum cracking pipe, precision steel pipe, carbon thin-walled steel pipe, alloy thin-walled steel pipe, stainless steel thin-walled steel pipe, special-shaped steel pipe, etc.

What are the applications of seamless steel pipe?

Nowadays, with the prosperity of economy and the improvement of science and technology, our society has been further developed, there are many places where the demand for steel pipe is great, so manufacturers have produced more and more different kinds of steel pipe, such as welded steel pipe, seamless steel pipe and so on.

Seamless pipes do not require any welding or joints and are derived from solid steel, which adds on to its strength and other characteristics including corrosion resistance. Round steel billets are heated and pushed over the piercing rod until the hollow shape is achieved. Subsequently, their length and thickness are controlled through extrusion techniques. Seamless steel pipes are known for their ability to withstand pressure more efficiently in comparison to other methods of pipe manufacturing processes, as well as being fast and cost-effective, so it is widely used in the oil and gas industry enterprises around the world to transport oil, gas and water.

In addition, because seamless pipes are able to withstand high pressures, they are also widely used in high-pressure applications including refineries, hydraulic cylinders, hydrocarbon industries, and in Oil and Gas infrastructure, where personnel and plant safety needs to be ensured through zero leakage policies.

Seamless pipes do not require any welding or joints and are derived from solid steel, which adds on to its strength and other characteristics including corrosion resistance. Round steel billets are heated and pushed over the piercing rod until the hollow shape is achieved. Subsequently, their length and thickness are controlled through extrusion techniques. Seamless steel pipes are known for their ability to withstand pressure more efficiently in comparison to other methods of pipe manufacturing processes, as well as being fast and cost-effective, so it is widely used in the oil and gas industry enterprises around the world to transport oil, gas and water.

In addition, because seamless pipes are able to withstand high pressures, they are also widely used in high-pressure applications including refineries, hydraulic cylinders, hydrocarbon industries, and in Oil and Gas infrastructure, where personnel and plant safety needs to be ensured through zero leakage policies.

The advantages of seamless steel pipe.

1. Strength: Seamless pipes come with the obvious advantage of having no seam and therefore no chance of a weak seam. This means that typically, seamless pipe can withstand 20% more working pressure than welded ones of the same material grade and size.

2. Resistance: The lack of seam means that seamless pipe can offer higher resistance to corrosion because there is less opportunity for things like impurities and defects that can more commonly occur along a weld.

3. Less Testing: It goes without saying that seamless pipes don’t require testing for weld integrity – no weld means no test!

4. Used in harsh conditions: seamless pipes perform well under harsh conditions, which means they can be used in extremely cold or hot environments.

2. Resistance: The lack of seam means that seamless pipe can offer higher resistance to corrosion because there is less opportunity for things like impurities and defects that can more commonly occur along a weld.

3. Less Testing: It goes without saying that seamless pipes don’t require testing for weld integrity – no weld means no test!

4. Used in harsh conditions: seamless pipes perform well under harsh conditions, which means they can be used in extremely cold or hot environments.

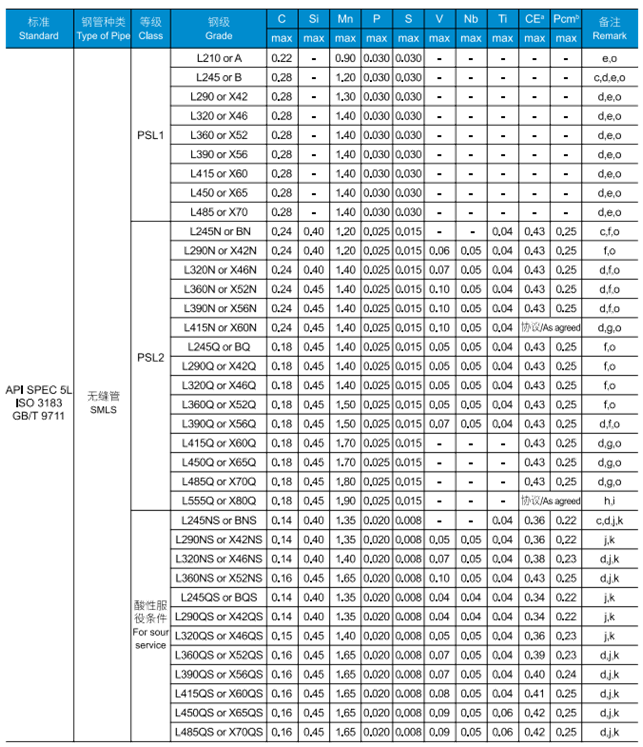

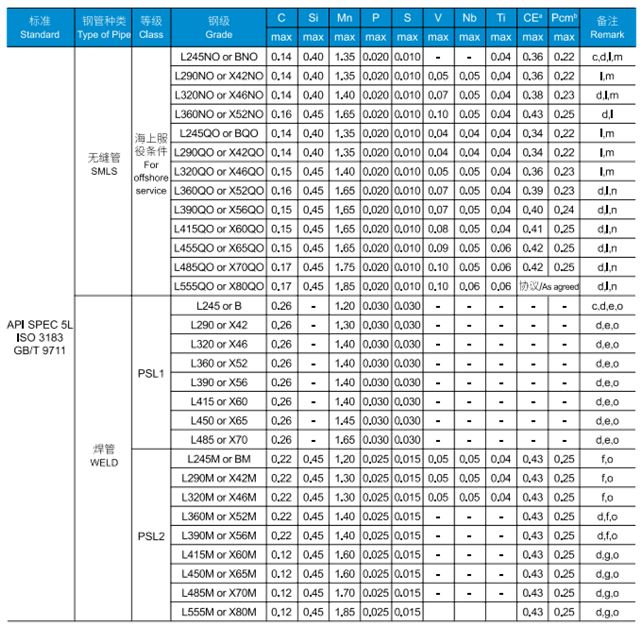

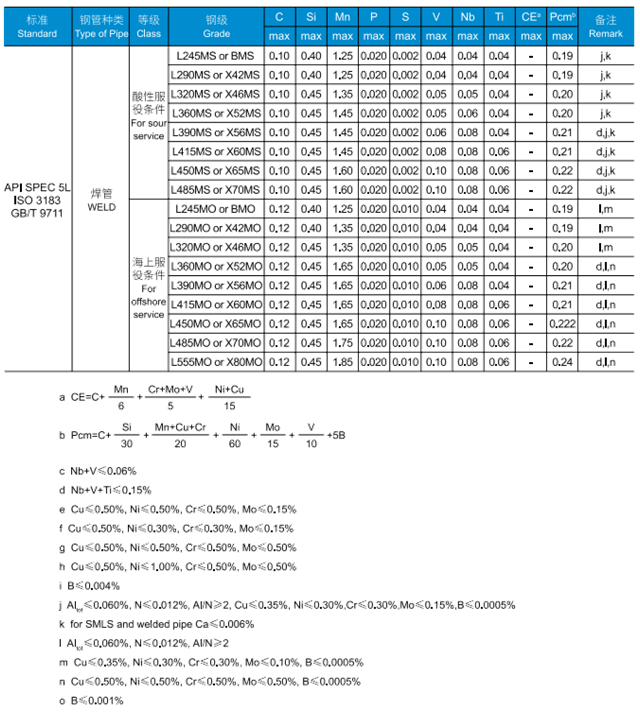

Chemical composition of API 5L Line Pipe

Our company`s advantages:

1. Quick Respond2. Reasonable Price

3. Abundant stock and prompt delivery

4. Flexible payment terms

5. Rich experiences in manufacturing and exporting

6. Excellent Quality

Why choose us to buy line pipe ?

As a leading line pipe distributor, Metleader has been exporting line pipes with big quantity to many countries and areas. Our company have been passed several certificates including ISO9001: 2008, ISO14001, OHSAS18001, CE certificate, one member of supplier system of Sinopec, and CNPC. In situations like high pressure, temperature, and corrosion, our Carbon Steel Pipes are perfectly suitable. We will provide the best service to our customers. welcome your inquiry timely sales@metleader.com .