Line Pipe

Home > Products > Steel Pipes > Line Pipe

Something you need to know about steel pipes

SPECIFICATIONS

Steel pipes are long and hollow tubes that are used for many different applications in a variety of places. Such as conveying fluids and powdery solids, exchanging heat, making machine parts and containers and so on. It is also an economical type of steel and its versatility makes pipes the most often used product that is produced by the steel industry.

Something you need to know about steel pipes |

|

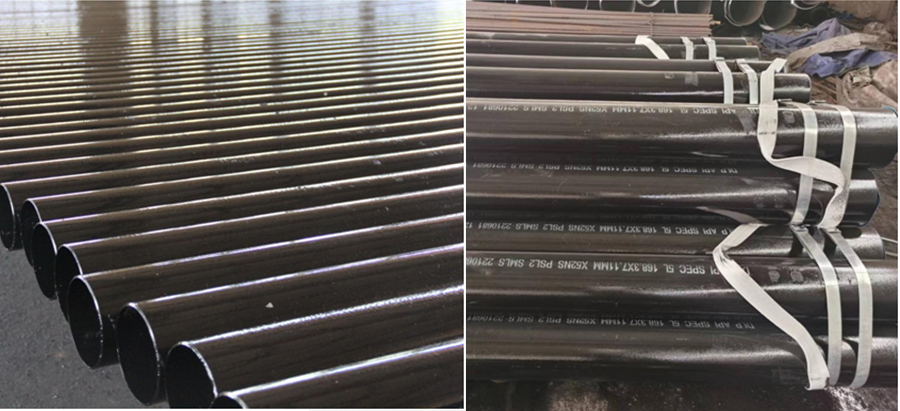

| Material Standard | ASTM, ASME and API |

| Grades | API 5L Gr. X42/X46/X52/X56/X60/X65/X70/X80and higher. PSL-1/PSL-2. ASTM A106 Gr. B/C. ASTM A53 Gr. B |

| Steel Pipe Dimensions | 1/2 inch to 12 inch, 14 inch, 16 inch, 18 inch, 20 inch, and 24 inch for seamless. |

| Wall thickness | SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS to SCH 60. |

| Length Range | 20 FT (6 meter), 40FT (12 meter)or customized |

| Ends Type | Beveled ends, Plain ends |

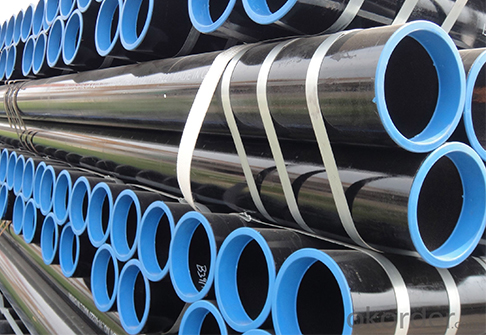

| End Protection | plastic Caps or iron Caps |

| Surface Coatings | Natural, Varnished, Black painting, 3PP, FBE and 3PE, Cladding and Lined etc. |

| Technical Methods | Hot rolling, Cold rolling or Cold drawing. |

| Testing Methods | Pressure test,Flaw detection,Eddy current testing, Hydrostatic testing or Ultrasonicexamination and also with chemical and physical property inspection |

What is steel pipe?

Steel pipes are long and hollow tubes that are used for many different applications in a variety of places. Such as conveying fluids and powdery solids, exchanging heat, making machine parts and containers and so on. It is also an economical type of steel and its versatility makes pipes the most often used product that is produced by the steel industry. Steel pipe production technology development began with the rise of the bicycle manufacturing, development of oil in the early years of the 19th century, two world war ships, boilers, aircraft manufacturing, after the second world war thermal power boiler manufacturing, chemical industry and the development of oil and gas drilling and transportation, effectively driving the steel pipe industry in the development of varieties, yield and quality. Steel pipe can be divided into two categories according to the production method: seamless steel pipe and seam steel pipe, seam steel pipe is divided into straight seam steel pipe and spiral seam welded pipe.

What are the applications of steel pipes?

Steel pipes are widely used in transportation, structures and manufacturing. With the development of society and the progress of science and technology, different steel pipe materials, design characteristics and production methods will continue to develop and change because of the different applications.

Transportation UsageThe most common use of steel pipes is for the transportation of products, as the characteristics of their raw materials are well suited for long-term installation. As the best way to transport oil and natural gas, steel pipe transportation has become the best choice for oil and natural gas transportation because of its larger volume and continuous flow, faster, more economical, less injection capital, less land, low cost, and the advantages of automatic control. Because of these advantages, many places also use steel pipes to transport solid energy, such as coal.

The principle of pipeline transportation is the use of the principle of the connector, through the pressure difference so that the fluid in the tube from high to low flow. During the conveying process, the pressure of the fluid decreases gradually due to friction loss and elevation difference. To pressurize the fluid, long-distance transport requires intermediate pumping or compressor stations.

The principle of pipeline transportation is the use of the principle of the connector, through the pressure difference so that the fluid in the tube from high to low flow. During the conveying process, the pressure of the fluid decreases gradually due to friction loss and elevation difference. To pressurize the fluid, long-distance transport requires intermediate pumping or compressor stations.

Structural Usage

The application of steel tube structure first started in Britain, and then in the 1980s, people had a deeper understanding of steel tube structure design, and there were some formal publications about steel tube. Steel pipe structure has been widely used not only in ocean engineering and bridge engineering, but also in industrial and civil buildings. In recent years, with the development of large public buildings, the space and span of the structure are more and more demanding. Because of its beautiful appearance, reasonable stress characteristics and superior economy, steel pipe structure has been widely used in modern industrial plants, warehouses, gymnasiums, exhibition halls, conference halls, terminals, stations and office buildings, commercial and residential buildings, hotels and other buildings.

Manufacturing Usage

Steel pipes have many different uses in manufacturing. Guardrails are one of the most common uses, providing safety features not only for stairs and balconies, but also for cyclists and pedestrians on the street. In addition., steel tubes can also be used as safety bollards to isolate vehicles and protect people, buildings or infrastructure. Third, steel pipe is also a choice for outdoor site decoration. Finally, many commercial bicycle frames are made of bent steel pipes. This has the advantage that steel's high toughness and strength make it resistant to thieves.

Pipe Types

Steel pipe can be divided into two categories according to the production method: seamless steel pipe and welded steel pipe, seam steel pipe is divided into straight seam steel pipe and spiral seam welded pipe.

Seamless PipesSeamless steel pipe is a circular pipe having a hollow section and no seams around it. The seamless steel pipe is made of carbon steel, alloy steel, stainless steel ingot or solid tube blank, and then is made by hot rolling, cold rolling or cold drawing. The quality of end product – tubes, entirely depends upon both factors – quality control during the manufacturing process and the initial condition and quality of raw materials. Seamless steel tubes can be divided into hot rolled seamless tubes, cold drawn tubes, precision tubes, hot expanding tubes, cold spinning tubes and extruded tubes. The most significant advantage of seamless pipes is that they can be produced in heavy and thick wall thicknesses.

Due to their having no weld seam, makes they to be considered as exhibiting better mechanical properties and corrosion resistance than seamed pipes. Seamless steel pipe can be used as a pipeline conveying fluid, such as the pipeline conveying oil, natural gas, gas, water and some solid materials. Compared with solid steel such as round steel, seamless steel tube has the same flexural and torsional strength and light weight, so it is widely used in the manufacture of structural parts and mechanical parts, such as oil drill pipe, automobile drive shaft, bicycle frame and steel scaffolding used in construction, etc.

Due to their having no weld seam, makes they to be considered as exhibiting better mechanical properties and corrosion resistance than seamed pipes. Seamless steel pipe can be used as a pipeline conveying fluid, such as the pipeline conveying oil, natural gas, gas, water and some solid materials. Compared with solid steel such as round steel, seamless steel tube has the same flexural and torsional strength and light weight, so it is widely used in the manufacture of structural parts and mechanical parts, such as oil drill pipe, automobile drive shaft, bicycle frame and steel scaffolding used in construction, etc.

Welded Pipes

Welded pipes is steel plate or steel belt, and the surface is a pipe with welding ribs after cutting, bending, welding and other processes. The main advantages of welded pipes are their lower inherent cost, narrower tolerances for wall thickness, concentricity (OD/ID) and internal surfaces that can be checked prior to manufacture. Welded steel pipe is divided into furnace welding pipe, electric welding (resistance welding) pipe and automatic arc welding pipe because of its different welding forms into straight seam welding pipe and spiral welding pipe two kinds, because of its end shape is divided into round welding pipe and special-shaped (square, flat, etc.) welding pipe. Seamed pipes offer tighter tolerances but thinner wall thickness rather than seamless pipes. Welding pipe can be used for water pipeline, gas pipeline, heating pipeline, electrical pipe and so on.

Welded steel pipe production process is simple, high production efficiency, variety specifications, less investment in equipment, but the general strength is lower than seamless steel pipe. Since the 1930s, with the rapid development of high quality strip continuous rolling production and the progress of welding and inspection technology, the weld quality has been continuously improved, and the varieties and specifications of welded steel tubes have increased day by day, and the seamless steel tubes have been replaced in more and more fields.

Why choose us to buy steel pipes ?

As a leading line pipe distributor, Metleader has been exporting line pipes with big quantity to many countries and areas. Our company have been passed several certificates including ISO9001: 2008, ISO14001, OHSAS18001, CE certificate, one member of supplier system of Sinopec, and CNPC. In situations like high pressure, temperature, and corrosion, our Carbon Steel Pipes are perfectly suitable. We will provide the best service to our customers. welcome your inquiry timely sales@metleader.com .

Our company`s advantages:

Quick Respond Reasonable Price

Abundant stock and prompt delivery

Flexible payment terms

Rich experiences in manufacturing and exporting

Excellent Quality