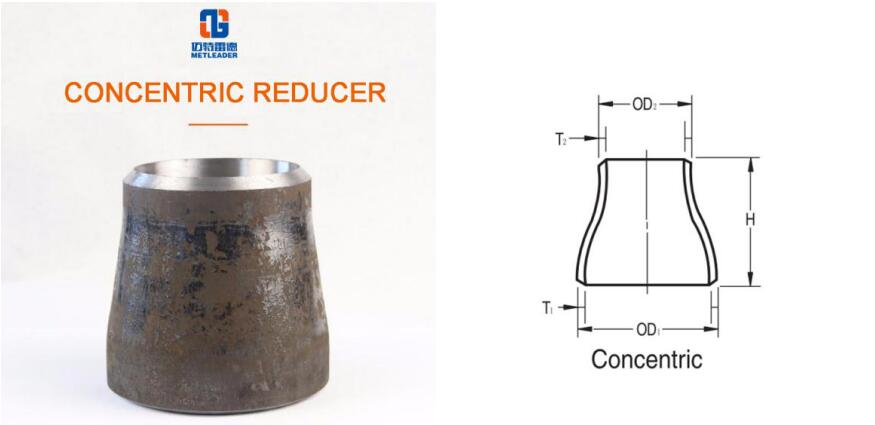

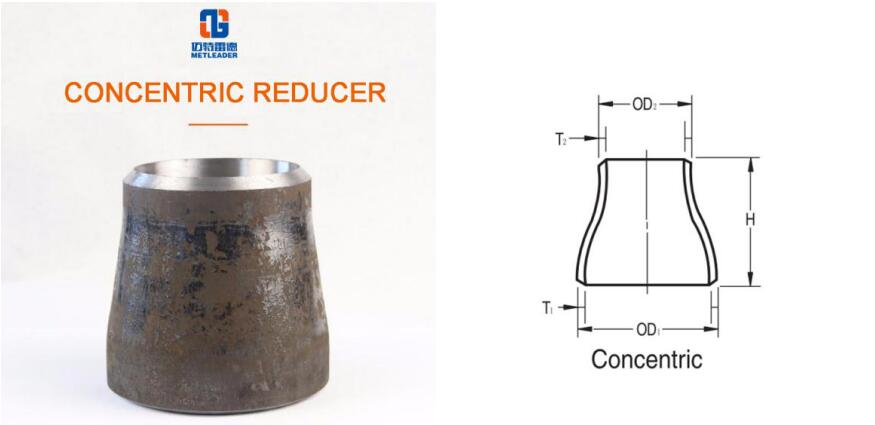

Concentric Reducer Supplier

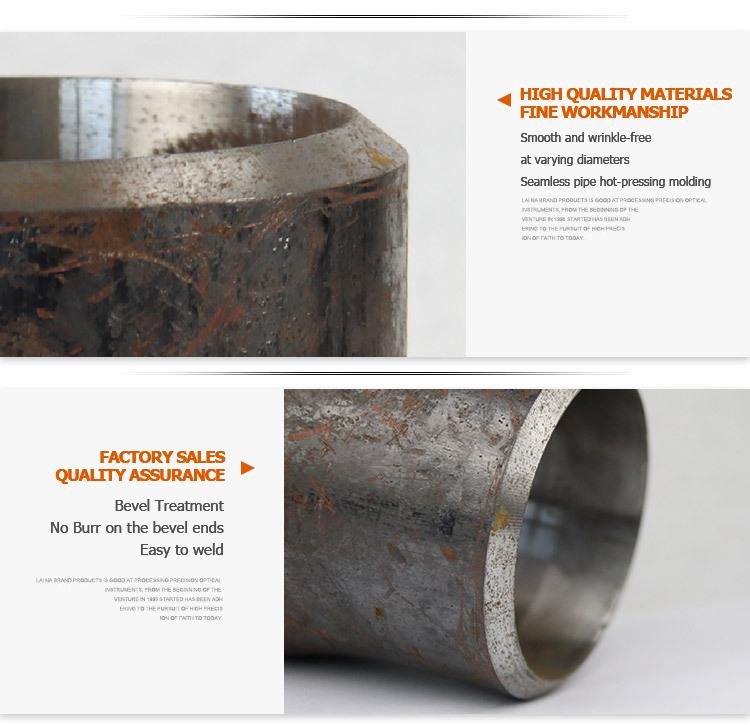

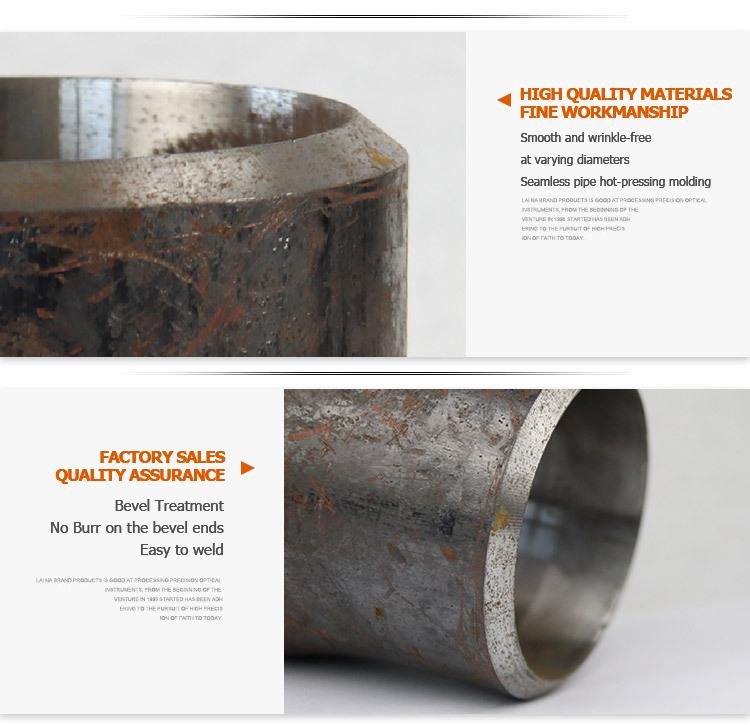

Our company mainly produces AMSE, DIN, GOST, JIS pipefittings, such as export steel reducer, including carbon steel, stainless steel, alloy steel concentric reducer and eccentric reducer. As a 36 production experience of the eccentric reducer and concentric reducer suppliers, our production process is very advanced, strict production processes, testing equipment perfect. We produce and export products, reliable quality and reasonable price.

The process of concentric size reducer:

A.Shrink diameter/enlarged diameter forming

As one of the concentric reducer Suppliers, in the production process of the reducer, often adopt shrink diameter or expanding the neck forming process. The necking forming process of the size head is to put the Tube billet which is equal to the big end diameter of the large and small head into the forming die, and the metal can be formed along the mold cavity by pressing along the axial direction of the tube billet. According to the size of the reducer, it is divided into one pressing forming or several pressing forming. The enlarged diameter of the size head is a tube billet smaller than the big end diameter of the reducer, and the inner diameter of the tube billet is formed with the internal die.

The expanding process mainly solves the situation that the reducer with large diameter is not easy to be formed by reducing diameter, and it is sometimes combined with the method of enlarging diameter and reducing diameter according to the need of material and product forming.

B.Stamping forming

As one of the concentric reducer Suppliers, in the production process of the reducer, often use stamping molding process. In addition to the use of steel pipe as raw material production size, the part of the reducer can also be used sheet metal stamping process for production. The shape of the die used for drawing refers to the size design of the inner surface of the head, and the sheet metal is pressed and drawn with the die. In the process of shrinking or expanding deformation, the cold pressure or hot pressing is determined according to different material and changing diameter.

Under normal circumstances, as far as possible the use of cold pressure, but a number of variable diameter caused by serious processing hardening of the situation, the thickness of the thickness of the case or alloy steel materials should use hot pressing.

The advantages of the forming process of concentric reducer:

1. Does not need the tube billet as the raw material, may economize the tube making equipment and the mold expense, and may obtain any big diameter and the wall thickness relatively thin size head.This size of the head of the raw material is more special, do not need to add raw materials, in the process of easy control.

2. Without the need of tube billet as raw material, can save pipe equipment and mold costs, and can be arbitrarily large diameter and relatively thin wall thickness of carbon steel elbow. 3. Due to the above two reasons, the manufacturing cycle can be shortened and the production cost greatly reduced.Because it does not require any special equipment, especially suitable for on-site processing of carbon steel size head.

Concentric reducer main application field:

1. When the flow of fluid in the pipeline changes, such as increase or decrease, the flow rate requires little change, the need to adopt different diameter pipe.

2. With the instrument, such as flowmeter, regulating valve joints, in order to match the instrument's joints, also need to adopt different diameter pipe.

3. Pump imports, in order to prevent cavitation.

The process of concentric size reducer:

A.Shrink diameter/enlarged diameter forming

As one of the concentric reducer Suppliers, in the production process of the reducer, often adopt shrink diameter or expanding the neck forming process. The necking forming process of the size head is to put the Tube billet which is equal to the big end diameter of the large and small head into the forming die, and the metal can be formed along the mold cavity by pressing along the axial direction of the tube billet. According to the size of the reducer, it is divided into one pressing forming or several pressing forming. The enlarged diameter of the size head is a tube billet smaller than the big end diameter of the reducer, and the inner diameter of the tube billet is formed with the internal die.

The expanding process mainly solves the situation that the reducer with large diameter is not easy to be formed by reducing diameter, and it is sometimes combined with the method of enlarging diameter and reducing diameter according to the need of material and product forming.

B.Stamping forming

As one of the concentric reducer Suppliers, in the production process of the reducer, often use stamping molding process. In addition to the use of steel pipe as raw material production size, the part of the reducer can also be used sheet metal stamping process for production. The shape of the die used for drawing refers to the size design of the inner surface of the head, and the sheet metal is pressed and drawn with the die. In the process of shrinking or expanding deformation, the cold pressure or hot pressing is determined according to different material and changing diameter.

Under normal circumstances, as far as possible the use of cold pressure, but a number of variable diameter caused by serious processing hardening of the situation, the thickness of the thickness of the case or alloy steel materials should use hot pressing.

The advantages of the forming process of concentric reducer:

1. Does not need the tube billet as the raw material, may economize the tube making equipment and the mold expense, and may obtain any big diameter and the wall thickness relatively thin size head.This size of the head of the raw material is more special, do not need to add raw materials, in the process of easy control.

2. Without the need of tube billet as raw material, can save pipe equipment and mold costs, and can be arbitrarily large diameter and relatively thin wall thickness of carbon steel elbow. 3. Due to the above two reasons, the manufacturing cycle can be shortened and the production cost greatly reduced.Because it does not require any special equipment, especially suitable for on-site processing of carbon steel size head.

Concentric reducer main application field:

1. When the flow of fluid in the pipeline changes, such as increase or decrease, the flow rate requires little change, the need to adopt different diameter pipe.

2. With the instrument, such as flowmeter, regulating valve joints, in order to match the instrument's joints, also need to adopt different diameter pipe.

3. Pump imports, in order to prevent cavitation.

Previous:classification of Carbon steel pipe fittings

Next:keeping counterfeits out of the supply chain of carbon steel pipe fittings

Next:keeping counterfeits out of the supply chain of carbon steel pipe fittings