Classification of Carbon steel pipe fittings

When the pipeline needs to be connected, branched, turned, and reduced in diameter, it needs to be solved by pipe fittings, and different pipe fittings need to be used for different pipelines. Commonly used carbon steel pipe fittings include carbon steel elbows, tees, reducers, and pipe joints.(1) Carbon steel Pipe fittings

1. Threaded pipe fittings

2. Stamped pipe fittings and welded pipe fittings

3. High pressure elbow (high pressure pipe fitting)

(2) Attachments

Purge joint

2. Head

3. Boss

Blind flange

Classification, nature and use of flanges and valves (note the contrast)

(1) Flanges and gaskets

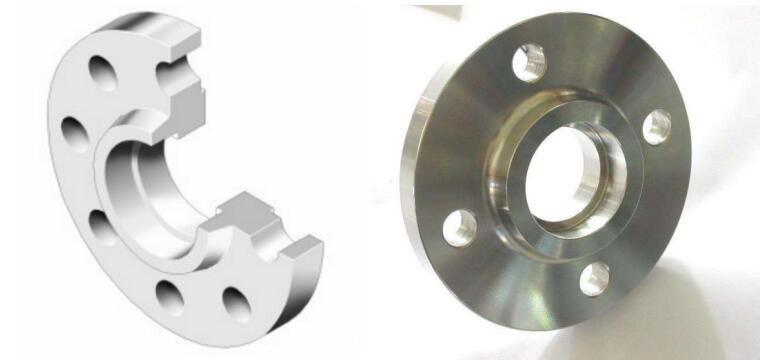

Flat welding flange

Flat welding flanges are the most commonly used ones for medium and low pressure industrial piping. When the flat welding flange is fixed with the pipe, the flange is sleeved at the pipe end, and the inner and outer ports of the flange are welded to fix the flange. Flat welding flange is suitable for nominal pressure not exceeding 2.50MPa.

2. Butt welding flange

Butt weld flanges are also known as high neck flanges. It has high strength, is not easy to deform, and has good sealing performance. Butt weld flanges are divided into the following forms:

(1) Smooth butt welding flange.

(2) Concave-convex seal facing the welding flange.

(3) The gutter seal faces the welding flange.

(4) Trapezoidal groove seal facing welding flange.

3. Flange movable flange

The flange of the pipe flange is mostly used for non-ferrous metals such as copper and aluminum and stainless steel pipes. The advantage is that since the flange can move freely, the flange is very convenient when threading the screw; the disadvantage is that it cannot withstand large pressure.

4. Welding ring movable flange

The welding ring movable flange is mostly used for the connection of thick stainless steel pipe flanges on the pipe wall. The material of the flange is Q235 and Q255 carbon steel. The connection method is that the welding ring with the same material as the pipe is directly welded to the pipe end, and the welding ring is used as the sealing surface, and the sealing surface has two types of smooth and grooved.

5. Threaded flange

Threaded flanges are flanges that are threaded to the end of the pipe and are available in both high and low pressures. The high-pressure thread is characterized in that the flange is not in contact with the medium in the tube, and the installation is also convenient. Low-pressure threaded flanges have now been gradually replaced by flat-welded flanges.

6. Gasket

(1) Rubber asbestos pad

The rubber asbestos pad is the most used gasket for flange connection and can be applied to many media such as steam, gas, air, brine, acid and alkali.

(2) Rubber gasket

Rubber gaskets have a certain degree of corrosion resistance. The gasket is characterized by the elasticity of the rubber to achieve a better sealing effect, and is commonly used for conveying pipe flange connections of low pressure water, acid and alkali.

(3) plastic gasket

Plastic gaskets are suitable for conveying flange connections of various corrosive pipes. Commonly used plastic gaskets include polyvinyl chloride gaskets, Teflon gaskets and polyethylene gaskets.

Previous:Packaging requirements and specifications for ASME pipe fittings

Next:Concentric Reducer Supplier

Next:Concentric Reducer Supplier