weld neck high pressure flanges

1.What is weld neck high pressure flange?Weld neck flanges have a long tapered hub and are usually used for high pressure applications. Weld neck flange is easily identified at the long conical hub, gradually changing from pipe or fitting to wall thickness.Weld flange is the most widely used flange in process pipeline. It has the highest level of joint integrity due to pipeline butt welding. Weld neck flanges are bulky and costly compared with other types of flanges.

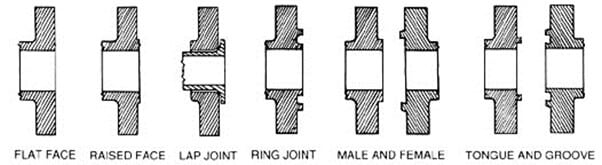

2.The sealing face of weld neck pipe flange.

There are several types of sealing face fro weld neck flange.

Flat Face (FF)

Raised Face (RF)

Ring Joint (RTJ)

Tongue and groove (TG)

Male and Female type (FM)

Making short introduction about two types.

Flat face steel flange

As the name suggests, flat face flanges have flat surfaces.When the reverse flange is flat, use a flat flange.This mainly occurs with cast iron equipment, valves and professional connections.When using flat flanges, use a full washer.

Raised face weld neck flange

The RF flange has a small protrusion from the face around the hole.The gasket seats on this raised surface.The height of the convex surface depends on the pressure-temperature rating of the flange, which is known as a class of flanges.For 150 # and 300 # raised surfaces the height is 1/6 "and above 300 # the height is 1/4".Inner hole circle type gaskets are used with raised flanges.

The flange pressure type

Weld neck flanges are specified as 150 #, 300 #, 400 #, 600 #, 900 #, 1500 # and 2500 # according to their pressure and temperature classes. Large diameter flanges of 24 "to 60" are available up to 900 # class. The pressure-temperature rating is the maximum allowable working pressure and celsius temperature in the bar.

The higher the rating, the heavier the flange, can withstand higher pressure and temperature.As the temperature rises, the pressure drops, and vice versa. Note that different materials have different pressure levels.

Advantages of weld neck flange:

Welding neck steel pipe flange is applied for high pressure, high temperature, and low temperature because of welding connection.

The weld neck flange can be distributed the stress very good through its conical neck.

Inspection for welding joint is easily, such as radiographic testing.

Disadvantages of welding neck flange:

Weld neck flanges are big volume, heavy, expensive, which making them more prone to collision during transportation.

Welding neck flange is widely used, the range of use is determined according to different characteristics. It is mainly used in medium conditions, such as low-pressure non-purified compressed air and low-pressure circulating water.Suitable for connection of steel pipe with nominal pressure not exceeding 2.5mpa, the sealing surface of butt welding flange can be made into smooth, concave and convex, groove.Smooth welded butt flange has the largest application, the other two methods of butt welded flange is also commonly used.

Welding flange can withstand high temperature and high pressure, repeated bending and temperature fluctuation, reliable sealing performance.Concave and convex sealing surface is used for butt welding flange with nominal pressure of 0.25-2.5mpa.The main application environment is suitable.