Upgrading of carbon steel pipe production system

Our factory uses the international advanced production management system of carbon steel pipe fittings. The production management software is very simple to control the setting of raw materials. Just open the production management module, and the carbon steel pipe fittings can be manufactured under the module for material management settings. There are three ways to add BOM. When adding products, it can add BOM directly, import BOM and add BOM directly. At the same time, it supports infinite polarization and BOM unidirectional and reverse expansion, which effectively solves the problem of factory materials. The problem of inventory setting has fundamentally met the actual material management requirements of the factory.

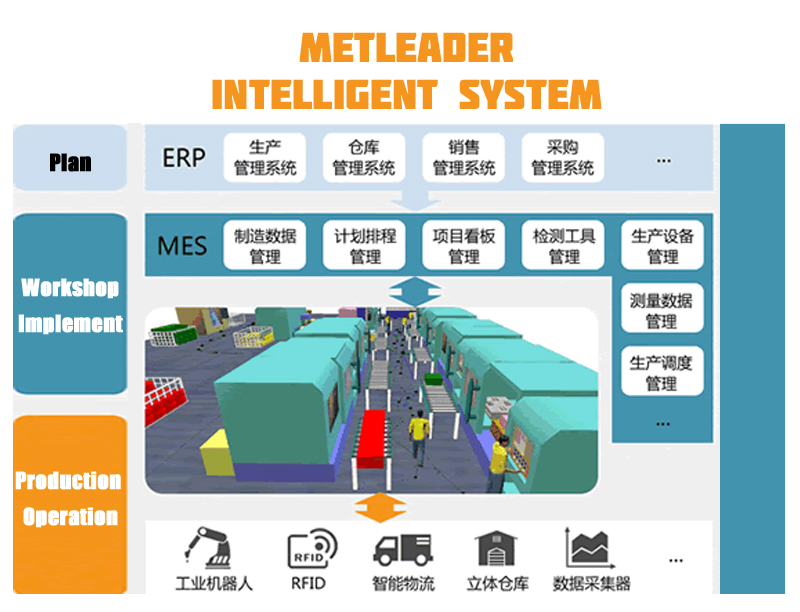

MES- manufacturing execution system for carbon steel pipe production

The MES system is a production information management system for the workshop execution layer of manufacturing enterprises. It can provide a reliable, perfect, comprehensive and feasible management platform for enterprises, including manufacturing data management, production scheduling management, inventory management and quality management, as well as human resources management, procurement management and so on.

SPC- statistical process control system for carbon steel pipe production

Statistical process control (SPC) is a tool for process control by means of data statistics. He can make a reasonable analysis and evaluation of the production process, and then the staff can find the problem according to the feedback information, so as to solve the problem in time, so as to avoid some losses.

Previous:Advantages of forming process of stamping elbow

Next:Facing environmental regulation, raw materials reserve

Next:Facing environmental regulation, raw materials reserve