The difference between pipe bend and elbow

Introduction

The fundamental difference between them is that the elbow is relatively shorter than the bend, and R equals 1D to 2D, but the bend is more than 2D. In the production process, the cold bending machine can be used to bend through the existing straight bending machine.No secondary corrosion is required for a single finish.But the elbow needs to be customized by the manufacturer, to do anti-corrosion, long order cycle.The price of elbow is higher than pipe bend. But cost performance is much higher than bend. As is known to all, pipe bend is easy to be damaged without antiseptic treatment, but it is cheap, so it is very commonly in some projects with low engineering requirements.Key Differences Between Pipe Bend and Elbow

1.Pipe bend is the general term for any deviation or change in direction in a pipe.This is a vague term that includes the elbow.2.Elbow is an engineering term. They are classified as 90 degrees or 45 degrees, short or long radius.

3.Pipe elbows have industrial standards and are limited in size, bending radius and Angle.The Angle is usually 45 or 90 degrees. All other offsets are classified as pipe bends.

4.Bend is usually made or manufactured according to the requirements of the pipe. But the elbows are prefabricated and standard, and can be made ready.

5.A bend is not a sharp angle, but an elbow. Pipe bend limits the amount of pressure that can be allowed to thin out to safely hold the fluid to be contained.Since the corners are prefabricated, cast or butt welded, they can be as sharp as a right angle and return 180 degrees.

6.The elbow is standard, but the elbow is custom made.

7.Where the pipe is bent and does not involve welding, the pipe has less friction and flows more smoothly. In a bend, welding causes some friction.

8.All elbows are bend, but all bends are not elbows.

9.The radius of the bend is greater than the elbow.

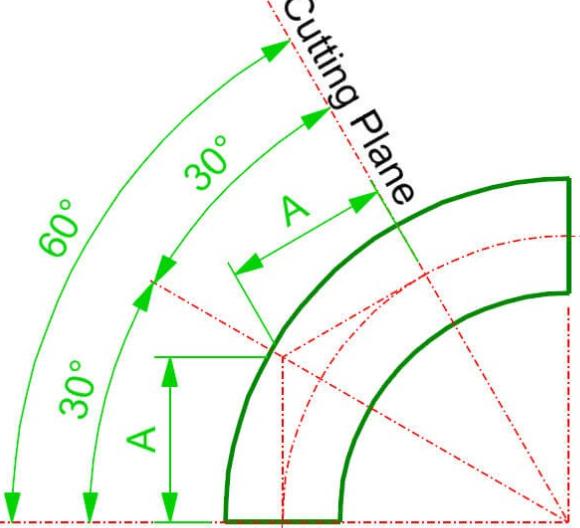

10.Usually, the most basic difference is the radius of curvature.The radius of curvature of a bend is usually between one and two times the diameter of the pipe.The bending radius of curvature is more than twice the diameter.

What is pipe bend?

A pipe bend is a curved section of piping that changes the direction of fluid flow within a pipeline system. It is designed to have a gradual change in direction, typically with a larger radius than pipe elbows, resulting in smoother flow with minimal turbulence and pressure drop. Types of Pipe Bends

Types of Pipe Bends

Long Radius Bends: These have a larger radius, providing smoother flow and less resistance.

Short Radius Bends: Although less common, these have a smaller radius and are used where space constraints are significant.

Manufacturing Process

Cold Bending: Involves bending the pipe at room temperature using mechanical or hydraulic pressure.

Hot Bending: The pipe is heated to make it more pliable, then bent to the desired shape.

Induction Bending: Uses electric induction to heat a narrow band of the pipe, allowing for precise control over the bending process.

Advantages

Flexibility in Design: Pipe bends can be custom-made to fit specific angles and radii, providing flexibility in pipeline design.

Smooth Flow: The gradual curve of pipe bends results in smoother flow with less turbulence and pressure drop compared to elbows.

Reduced Wear: Smoother flow reduces wear and tear on the piping system, potentially increasing its lifespan.

Pipe bends are essential components in piping systems where maintaining efficient flow and minimizing pressure loss are critical considerations.

what is pipe elbow?

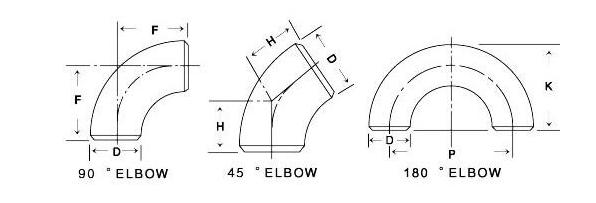

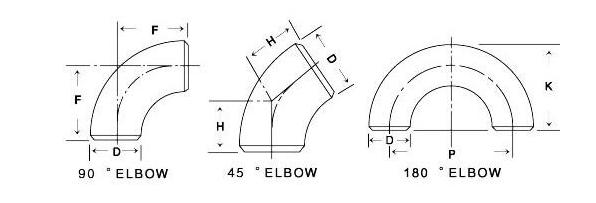

A pipe elbow is a standardized fitting used in piping systems to change the direction of fluid flow. These components are essential for redirecting fluids at specific angles, commonly 45°, 90°, and 180°, and are widely used across various industries due to their versatility and ease of installation.

Types of Pipe Elbows

Short Radius Elbows (SR): These have a radius equal to the pipe diameter, resulting in a tighter turn and greater turbulence.

Long Radius Elbows (LR): These have a radius 1.5 times the pipe diameter, offering a smoother turn with less resistance and pressure drop.

Manufacturing Process

Forging: Most elbows are forged from metals like steel to ensure strength and durability.

Casting: Some elbows are cast, especially those used in less demanding applications.

Machining: Additional machining processes are often used to achieve precise dimensions and smooth surfaces.

Advantages

Standardization: Elbows come in standardized angles and sizes, facilitating easy integration into various systems.

Ease of Installation: Their standardized dimensions make them straightforward to install, reducing labor and time.

Versatility: Available in a range of materials and grades to suit different environmental conditions and pressure requirements.

Previous:5 Advantages Processing technology of Stamping elbow

Next:What is the useage of the line pipe?

Next:What is the useage of the line pipe?