Carbon Steel Pipe

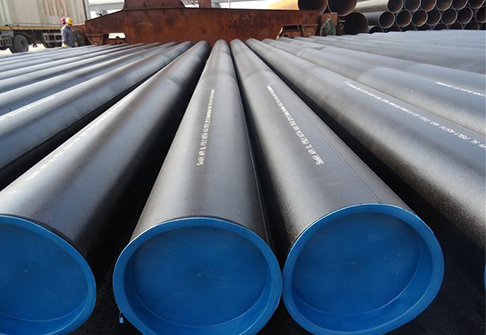

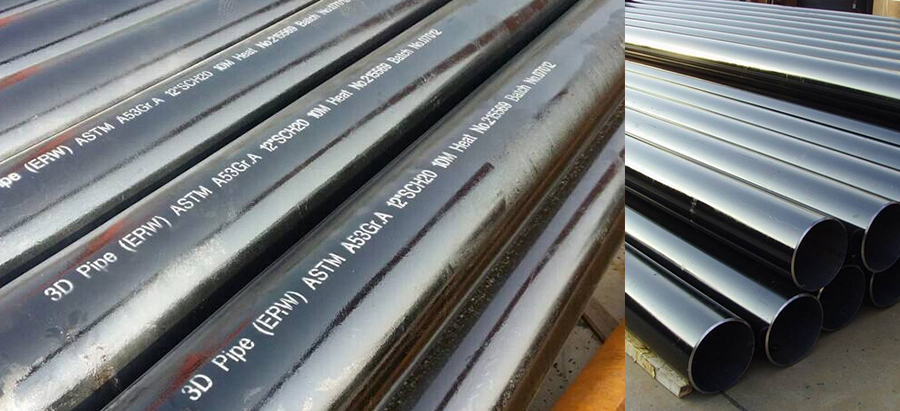

ERW carbon steel pipe - welded steel pipe

SPECIFICATIONS

What is ERW carbon steel pipe?

At present, the welded steel pipe is widely used in the fields of petroleum, natural gas and urban gas in China. According to the technology, the welded steel pipe is mainly divided into three kinds: straight seam resistance welding (ERW), spiral submerged arc welding (SSAW) and straight seam submerged arc welding (LSAW). The welded pipes produced by these three processes have their own positioning and advantages in the application field because of their different raw materials, forming processes, diameter size and quality.

| ERW carbon steel pipe - welded steel pipe | |

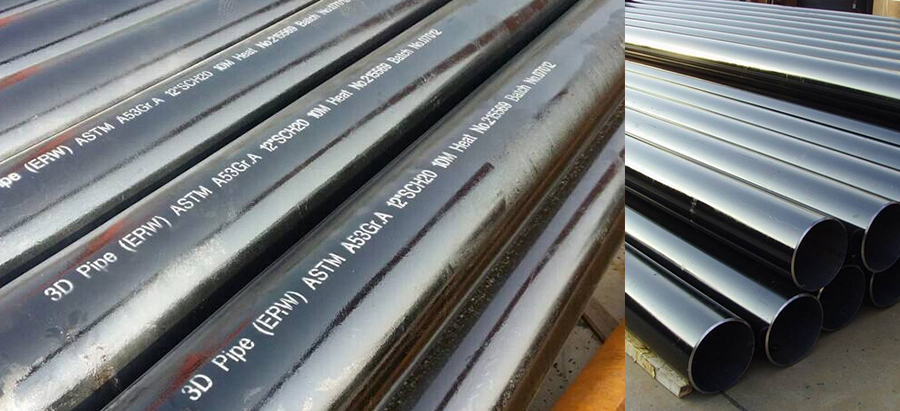

| Material Standard | ASTM, ASME and API |

| Size | 1/2 to 36 inch NB |

| Schedules | SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160 |

| Thickness | 3-12 millimeter |

| Length Range | 20 FT (6 meter), 40FT (12 meter)or customized |

| Ends Type | Beveled ends, Plain ends, Threaded |

| End Protection | plastic Caps or iron Caps |

ERW carbon steel pipe is a carbon steel pipe type with an additional black finish for corrosion resistance, which is manufactured through low or high frequency resistance. The weld is longitudinal. During the welding process of ERW welded steel pipe, heat will be generated when current flows through the contact surface of welding area. It will heat the two edges of the steel to a point where the edges can form a bond. At the same time, the edges of the billet steel melt and extrude together under the action of composite pressure.

Usually ERW carbon steel pipe maximum OD is 24” (609mm), for larger dimensions pipe will be manufactured in SAW.

Usually ERW carbon steel pipe maximum OD is 24” (609mm), for larger dimensions pipe will be manufactured in SAW.

ERW carbon steel pipe application and usage

ERW carbon steel pipe used for transporting gas and liquid objects such as oil and gas, could meet the low and high pressure requirement. In recent years, with the development of ERW technology, more and more ERW carbon steel pipes are widely used in aviation, aerospace, energy, electronics, automobile, light industry and other industrial sectors. It is one of the important welding processes.

Advantages of ERW carbon steel pipe

ERW carbon steel pipe represents resistance welding, resistance welding has the advantages of high production efficiency, low cost, material saving, easy automation and so on.

ERW carbon steel pipe manufacturer

In the past, due to the low level of metallurgical equipment and technology in my country, the width of the steel coil (plate) produced was limited and the quality was unstable. In addition to the use of seamless steel pipes with high cost and not necessarily high quality, the steel pipes with small diameters between 20-89mm are mainly straight seam pipes, and the quality is extremely low. In order to produce steel pipes with larger diameters, the process of spiral welding can only be used.

In the 1990s, with the continuous improvement of the level of metallurgical equipment and technology in my country, the width and quality performance of the plate (hot-rolled coil) as the raw material of the steel pipe have all improved, providing a low-cost, high-quality ERW straight seam electric resistance welded steel pipe. Reliable quality raw materials make it possible to produce medium and large diameter straight seam pipes, especially the pipeline steels produced by the four major steel mills in central enterprises - Baosteel, Anshan Iron and Steel, Wuhan Iron and Steel, and Panzhihua Iron and Steel Company - have superior performance. Among the domestic steel mills, Panzhihua Iron and Steel Co., Ltd. took the lead in introducing high-grade ERW straight seam pipe production lines from abroad. It changed the appearance of backward domestic ERW straight seam electric resistance welded steel pipe technology, small scale and poor quality in the past, and began to replace seamless pipes.

The spiral pipe enters the fields of petroleum, natural gas and city gas. Spiral welded pipe manufacturers for crude oil and petrochemical systems are also rushing to launch ERW straight seam electric resistance welded steel pipe production lines (such as Baoji Petroleum Steel Pipe Factory, North China Petroleum Steel Pipe Factory, Liaoyang Petroleum Steel Pipe Factory, Shashi Petroleum Steel Pipe Factory, Shengli Petroleum Steel Pipe Factory, etc.).

In the 1990s, with the continuous improvement of the level of metallurgical equipment and technology in my country, the width and quality performance of the plate (hot-rolled coil) as the raw material of the steel pipe have all improved, providing a low-cost, high-quality ERW straight seam electric resistance welded steel pipe. Reliable quality raw materials make it possible to produce medium and large diameter straight seam pipes, especially the pipeline steels produced by the four major steel mills in central enterprises - Baosteel, Anshan Iron and Steel, Wuhan Iron and Steel, and Panzhihua Iron and Steel Company - have superior performance. Among the domestic steel mills, Panzhihua Iron and Steel Co., Ltd. took the lead in introducing high-grade ERW straight seam pipe production lines from abroad. It changed the appearance of backward domestic ERW straight seam electric resistance welded steel pipe technology, small scale and poor quality in the past, and began to replace seamless pipes.

The spiral pipe enters the fields of petroleum, natural gas and city gas. Spiral welded pipe manufacturers for crude oil and petrochemical systems are also rushing to launch ERW straight seam electric resistance welded steel pipe production lines (such as Baoji Petroleum Steel Pipe Factory, North China Petroleum Steel Pipe Factory, Liaoyang Petroleum Steel Pipe Factory, Shashi Petroleum Steel Pipe Factory, Shengli Petroleum Steel Pipe Factory, etc.).