Customized products

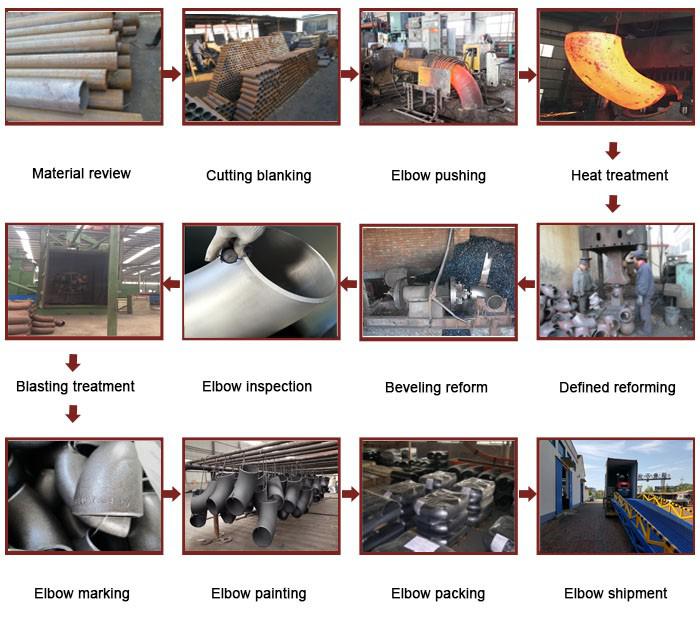

Pipe Elbow Manufacturing Process

SPECIFICATIONS

Pipe Elbow Manufacturing Process

Carbon steel pipe elbow, because of its different manufacturing process, we divide into hot-rolled (extruded) carbon steel elbow pipe fittings and cold-rolled carbon steel elbow pipe fittings. Cold rolling tube is also divided into circular tubes and special-shaped tubes.

Now let us to introduce the manufacturing process simply as below:

1.Cold rolling cs elbow pipe fittings: Round tube Billet---Heating--Drilling--Annealing--Acid washing--Blasting--Cold Rolling--Heat Treatment---Straighten--hydrostatic test--Marking---Storeage

The cold rolling method of seamless steel pipe is more complicated than that of hot-rolled extruded carbon steel pipe elbow. Their production process is basically the same as the first three steps. The difference is from the fourth step, the round tube billet after empty and annealing, use a special acidic liquid for pickling. After pickling, apply oil. Then followed by a multi-channel cold drawn (cold-rolled), special heat treatment. After heat treatment, it will be straightened. After straightening, the steel tube is sent to the crack machine (or hydrostatic test) for internal flaw detection. If there are cracks inside the steel pipe, bubbles and other problems will be detected. After quality inspection also through strict manual selection. After quality inspection, the paint is sprayed with the number, specifications, production batches and so on. and lifted from the crane into the warehouse.

2.Hot-rolled (extruded carbon steel elbow pipe fittings): round tube billet → heating → perforation → three-roll skew rolling, continuous rolling or extrusion → off pipe → sizing (or reducing) → cooling → straightening → hydrostatic test (or flaw detection) → labeling → warehousing

The raw material of rolled carbon steel elbow pipe is round tube billet, the tube billet is cut by cutting machine and processed into the billet of about one meter in length, and is sent to the furnace by conveyor belt. The billet is heated in a furnace, at a temperature of about 1200 degrees Celsius. The fuel is hydrogen or acetylene. Temperature control in the furnace is a key problem. After the Tube billet is released, it must be worn by a pressure piercing hole. Generally more common punch is the cone-shaped roller piercing machine, this type of piercing machine production efficiency, product quality, perforation expansion is large, can wear a variety of pipe fittings. After perforation, the round tube billet has been three-roll skew rolling, continuous rolling or extrusion. After extrusion to remove the tube sizing. The sizing machine rotates into the steel embryo punch through the conical bit at high speed to form a pipe fitting. The inner diameter of the pipe is determined by the length of the diameter of the drill bit. After the tube has been fixed, it enters into the cooling tower and cools through the water spray, and the pipe fittings are cooled and will be straightened. After straightening, the pipe is sent to the crack machine (or hydrostatic test) for internal flaw detection.