Customized products

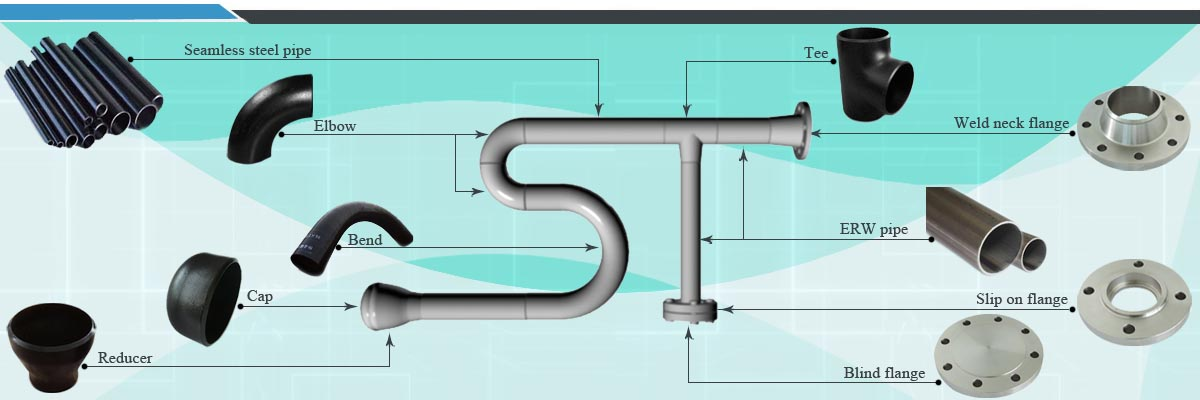

Introduct of steel pipe reducer

SPECIFICATIONS

This article mainly introduces the introduction of our company's reducers and how to control the quality in the production process.

The introduction about steel pipe reducers

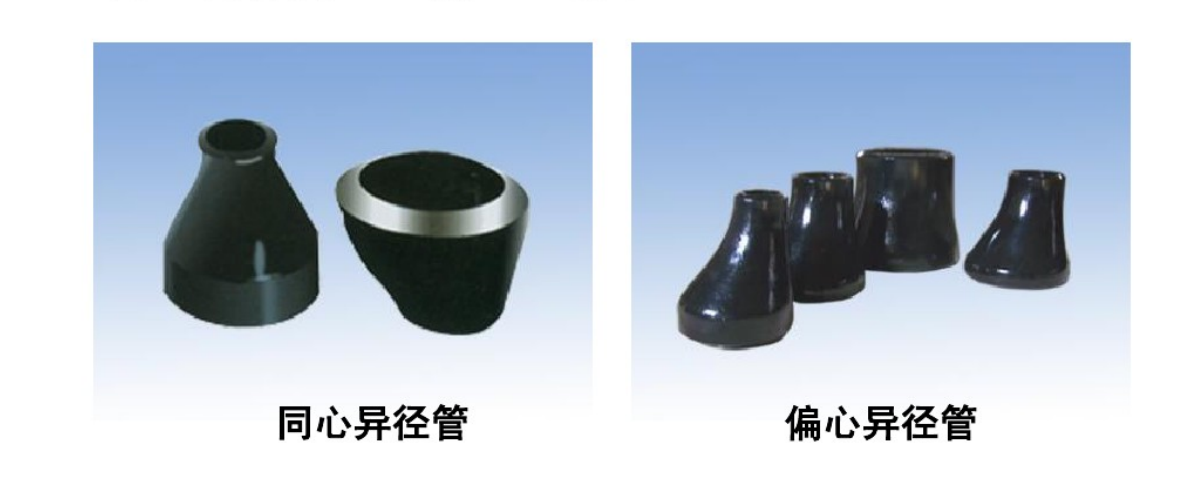

Reducer, also called large and small head, is used to connect two kinds of pipe with different diameters, which are divided into concentric reducer and eccentric reducer according to the category. According to the material including stainless steel, alloy steel, carbon steel and so on. Our company mainly produces carbon steel, alloy steel, and stainless steel pipe fittings.

The type of reducer materials

Carbon steel: ASTM/ASME A234 WPB、20#、Q235.Stainless steel:ASTM/ASME A403 WP 304-304L-304H-304LN-304N.

ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti.

ASTM/ASME A403 WP 321-321H ASTM/ASME A403 WP 347-347H.

Alloy steel: ASTM/ASME A234 WP 1-WP 12-WP 11-WP 22-WP 5-WP 91-WP911、15Mo3 15CrMoV、 35CrMoV.

Low temperature steel:ASTM/ASME A402 WPL3-WPL 6, 16Mn.

High performance steel: ASTM/ASME A860 WPHY 42-46-52-60-65-70.

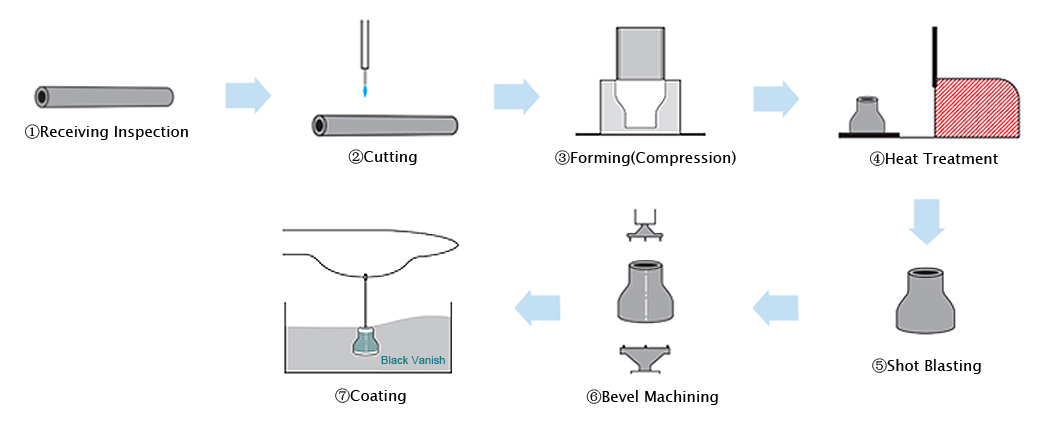

The production processing flow of reducer

1)Receiving inspection of raw material. It is the first compulsory chain to guarantee good quality. The testing items refer to chemical composition, mechanical capacity and metallographic analysis.2) Cutting raw material. Correctly and strictly controlling cutting size and proportion can ensure moderate cost.

3) Hot forming. In this step the raw material will be put into the reducer machine and heat it to get an reducer blank. The temperature and speed of hot forming determine the quality of reducer blank. If the quality of blank is very good which can reduce some cost. So it is very important to control the temperature and speed of hot forming.

4) Heat treatment. Reducer also need the heat treatment. The purpose of heat treatment is to eliminate the stress inside of reducer and the density is more evenly. It can help to get better mechanical property to reduce the risk of crack. Carefully recording the temperature of heat treatment and cooling time are the keys.

6) Short blasting. The purpose of short blasting is to remove the rust on the reducer. The size of sandblasting can affect the smooth of reducer surface, if the size is too big will lead to the surface is rough, so it is better to choose small size sand.

7) Bevel end machining. The angle of bevel end is different for different standard reducer. Correctly and strictly controlling the machining process to make sure the angle is qualified.

8) Coating. Generally the coating is black painting, vanish and anti-rust oil. No matter which type the surface should be smoothly.

All the production chains are actually very important, so the details of each chain must be recorded according to ISO requirement. It is the guarantee for good quality.

Strictly inspection for each step during the production process of reducer

Reinspection of raw materials: Chemical analysis, Mechanical property, Metallographic analysis (mainly analysis of grain size), MTC of raw material checking.Heat Treatment: The elbow made of carbon steel does not require heat treatment when the pushing temperature is higher than 750 degrees Celsius. Different materials have different heat treatment temperatures. Alloy steel materials and tees (including various materials) must undergo heat treatment to relieve stress. Heat treatment procedure (normalizing+tempering). Mechanical properties cannot be achieved by only tempering without normalizing. Reducers also require heat treatment to relieve stress.

Bevel end and surface treatment: the sequence of the two processes interchanged, it is better to do the surface treatment and then bevel end which makes the pipe surface more beautiful.

Finished product inspection: During testing, samples should be taken from different locations of the pipe fittings for chemical composition and mechanical property testing. At the same time, the diameter and wall thickness of pipe fittings should also be tested.

Non destructive testing/flaw detection: Both methods are used to detect cracks or welds in order to prevent pipe fittings from exploding during use.

Surface treatment: The surface of the reducer can be treated differently, such as spray painting, hot dip galvanizing, electroplating, etc., to improve its corrosion resistance and aesthetic.

The packing and shipping specifications of reducer

| 1 | Plywood pallet | 1. Flange pipe fittings that cannot be boxed shall be packaged using pallets; 2. Foreign trade pallets only use plywood 3. Each product on the tray is fixed in place, and large flanges are fixed with bolts |

|

| 2 | Plywood case | 1. Small single products shall be packaged in wooden boxes; 2. Reinforcing strips with basic colors on four sides; 3. External printing of Chinese or English logo and stacking identification; European style bottom plate for export products. |

|

| 3 | Carton | 1. Small quantities or express delivery products are packaged in cartons; 2. External printing of Chinese or English logo and stacking identification; 3. The packing shall be tight, and the incomplete parts shall be filled with foam. |

|

| 4 | Wrapping film | 1. Use winding film for palletizing products; 2. Tight, uniform and economical packaging; 3. External printing of Chinese or English logo and stacking identification; |

|

| 5 | Plastic bag/septa | 1. Single piece plastic bag set for stainless steel pipe fittings; 2. Stainless steel flanges are protected by spacers in layers. |

|

Customer feedback

After receiving our products, the customer recognized the quality very much, and sent us feedback drawings and factory construction drawings.