Customized products

Introduct of steel pipe tee fittings

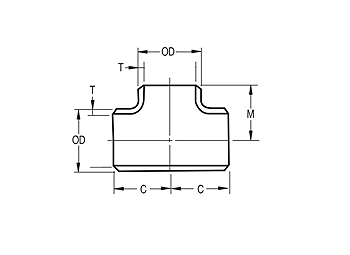

SPECIFICATIONS

This article mainly introduces the introduction of our company's reducers and how to control the quality in the production process.

The introduction about steel tee:

Steel Tee is a commonly used pipe component, which is usually applied to connect three pipes. It consists of three connections that allow fluid to flow in three directions. Tee has two types equal tee and reducing tee.

The advantages of Steel Tee:

1.Easy connection. Steel tee has many various of connection, it can be connected by welding threading, flanged etc which is very convenient.2.Strong pressure bearing capacity: The steel tee is made of high-strength steel, which has strong pressure bearing capacity and can withstand high pressure and temperature.

3. Good corrosion resistance: Steel tees are usually made of corrosion resistant materials such as stainless steel and alloy steel, which can withstand various corrosive media and have a long service life.

The type of steel tee materials

Carbon steel: ASTM/ASME A234 WPB、20#、Q235Stainless steel:ASTM/ASME A403 WP 304-304L-304H-304LN-304N

ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti

ASTM/ASME A403 WP 321-321H ASTM/ASME A403 WP 347-347H

Alloy steel: ASTM/ASME A234 WP 1-WP 12-WP 11-WP 22-WP 5-WP 91-WP911、15Mo3 15CrMoV、 35CrMoV

Low temperature steel:ASTM/ASME A402 WPL3-WPL 6, 16Mn, Q345

High performance steel: ASTM/ASME A860 WPHY 42-46-52-60-65-70

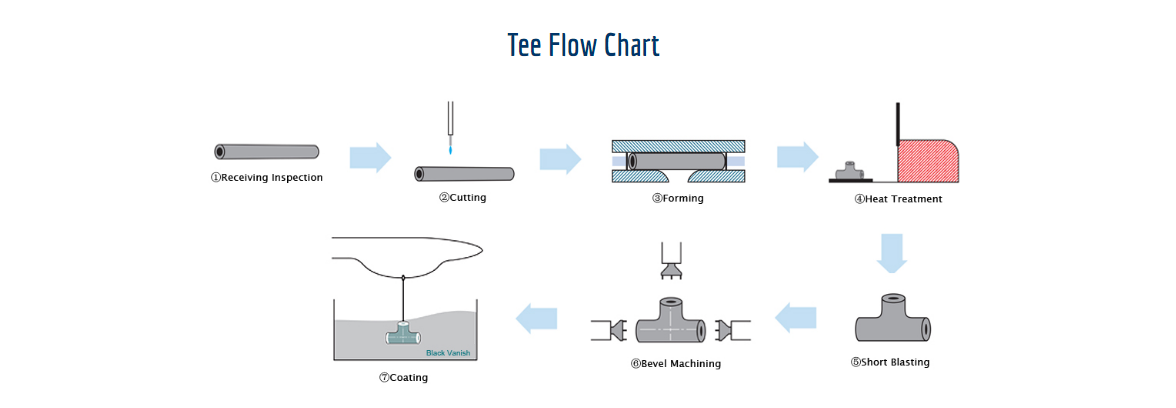

The production processing flow of carbon steel tee

1)Receiving inspection of raw material. It is the first compulsory chain to guarantee good quality. The testing items refer to chemical composition, mechanical capacity and metallographic analysis.2) Cutting raw material. Correctly and strictly controlling cutting size and proportion can ensure moderate cost.

3) Forming. There are two forming types for producing tee cold forming and hot forming. In this step the raw material will be put into the tee hydraulic machine, then getting the tee blanks. The temperature and speed of hot forming determine the quality of tee blank. If the quality of blank is very good which can reduce some cost. So it is very important to control the temperature and forming speed.

4) Heat treatment. For tee heat treatment is very important. The purpose of heat treatment is to eliminate the stress inside of tee and the density is more evenly. It can help to get better mechanical property to reduce the risk of crack at the branch. Carefully recording the temperature of heat treatment and cooling time are the keys.

5) Short blasting. The purpose of short blasting is to remove the rust on the tee. The size of sandblasting can affect the smooth of tee surface, if the size is too big will lead to the surface is rough, so it is better to choose small size sand.

6) Bevel end machining. The angle of bevel end is different for different standard tee. Correctly and strictly controlling the machining process to make sure the angle is qualified.

7) Coating. Generally the coating is black painting, vanish and anti-rust oil. No matter which type the surface should be smoothly.

All the production chains are actually very important, so the details of each chain must be recorded according to ISO requirement. It is the guarantee for good quality.

The manufacturing process of steel tee mainly includes forging, casting, welding, etc. Forging process is one of the most commonly used processes, which can ensure the high strength and wear resistance of steel. The casting process is mainly applicable to the manufacture of large and complex shaped steel tees. The welding process is the process of welding multiple steel plates into one body and making a steel tee. Different manufacturing processes can be selected based on actual needs.

The inspection of steel tee

1.Visual inspection: Firstly, conduct appearance inspection, including checking whether the surface of the tee has obvious defects or damages such as concavities, cracks, burrs, etc.2. Dimension inspection: Check the dimensions of carbon steel tees to confirm whether they meet the design requirements. Check whether the wall thickness, inner diameter, outer diameter, and other parameters of the tees meet the standard requirements.

3. Material inspection: Inspect the material of steel tee, including whether the material certificate, composition, hardness, and other parameters meet the requirements.

4. Pressure testing: Pressure test for steel tee to test their pressure resistance and check whether they can work properly under the specified pressure.

5. Magnetic Particle Testing: Perform magnetic particle testing on steel tees to check for defects such as cracks and defects on their surfaces.

6. Ultrasonic testing: Conduct ultrasonic testing on steel tees to check whether there are defects such as pores and inclusions inside.

The above are the routine testing steps for carbon steel tees, and other special tests may be required depending on the actual situation.

The application of steel tee fittings

Steel tees are widely used in industrial production, mainly in the following fields: 1.Petrochemical industry: Steel tees are widely used in the petrochemical industry, mainly for connecting oil pipelines, chemical pipelines, etc.2.Pharmaceutical industry: Steel Tees are also used in the pharmaceutical industry to connect various drugs.

| 1 | Plywood pallet | 1. Flange pipe fittings that cannot be boxed shall be packaged using pallets; 2. Foreign trade pallets only use plywood 3. Each product on the tray is fixed in place, and large flanges are fixed with bolts |

|

| 2 | Plywood case | 1. Small single products shall be packaged in wooden boxes; 2. Reinforcing strips with basic colors on four sides; 3. External printing of Chinese or English logo and stacking identification; European style bottom plate for export products. |

|

| 3 | Carton | 1. Small quantities or express delivery products are packaged in cartons; 2. External printing of Chinese or English logo and stacking identification; 3. The packing shall be tight, and the incomplete parts shall be filled with foam. |

|

| 4 | Wrapping film | 1. Use winding film for palletizing products; 2. Tight, uniform and economical packaging; 3. External printing of Chinese or English logo and stacking identification; |

|

| 5 | Plastic bag/septa | 1. Single piece plastic bag set for stainless steel pipe fittings; 2. Stainless steel flanges are protected by spacers in layers. |

|