How to choose the right elbow in 11 elbow in projects ?

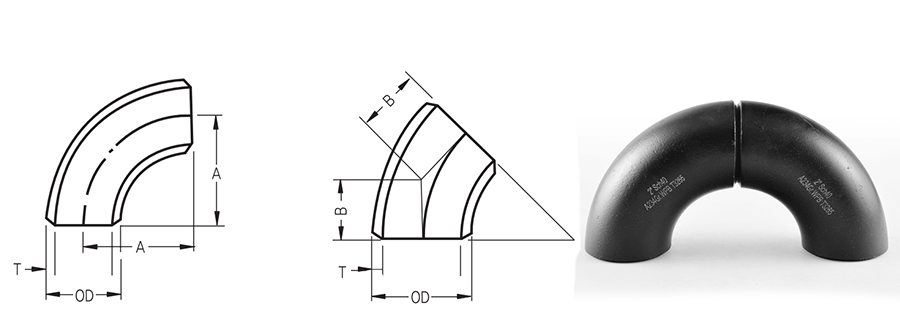

An elbow is a pipe connection used to change the direction of a pipe. They come in many different types, some of which include:1.180 degree elbow: this elbow makes the pipe change direction 1800 degrees.

2.90-degree elbow: This elbow changes the direction of the pipe by 90 degrees and is often called a "right-angle elbow".

3. 45-degree elbow: This elbow changes the direction of the pipe by 45 degrees and is often called a "bevel elbow".

4. Long radius elbow: This type of elbow has a longer curved portion than the standard elbow and is usually used when a greater curvature is required.

5. Short radius elbow: Contrary to the long elbow, this elbow has a shorter curved section for tight spaces.

6. Welded elbows: These elbows usually need to be welded to the pipe to ensure sealing and strength.

7. Threaded Elbows: These elbows have threaded connections for easy installation onto other threaded plumbing components.

8. Corrugated elbows: These elbows have a corrugated shape and are usually used for flexible pipe connections.

9. Y-shaped elbow: This elbow divides the pipe into two directions, similar to the shape of the letter "Y".

10. T-shaped elbow: This elbow divides the pipe into three directions, similar to the shape of the letter "T".

11. Cross-shaped elbow: This elbow divides the pipe into four directions, similar to the shape of the letter "ten".

Key factors to consider when choosing the right elbow for engineering design:

1. Elbow type: first determine the type of elbow you need, whether it is 90 degrees, 45 degrees, Y type, T type, cross type or other types. This will depend on the design and functional requirements of the piping system.2. Pipe diameter: The diameter of the elbow must match the diameter of the pipe to ensure that the fluid can pass through smoothly, reducing resistance and pressure drop.

3. Elbow radius: The radius of the elbow determines the degree of curvature of the curve. Larger radii generally reduce pressure drop and drag, but require more space. Smaller radii allow for greater bends in confined spaces, but may increase drag.

4. Material selection: choose materials suitable for the pipeline medium and working conditions. Different media and environments may require different types of materials, such as carbon steel, stainless steel, copper, PVC, etc.

5. Elbow connection method: Consider the connection method of the elbow, such as welding, thread, flange, etc. Make sure the connection method matches the requirements of the piping and system.

6. Elbow angle: Determine the angle of the elbow as required, such as 90 degrees, 45 degrees or others. Smaller angles generally produce less pressure drop, but may require more elbows to change pipe direction.

7. Environmental conditions: Consider the environmental conditions of the piping system, such as temperature, pressure, corrosiveness and other factors, and select elbow materials and designs that are resistant to these conditions.

8. Cost and Availability: Consider the cost of the elbow and supply availability to ensure the project is on budget and on time.

9. Standards and specifications: Follow applicable industry standards and specifications to ensure that elbow selection meets safety and performance requirements.

The above are some suggestions from metleader pipeline for you in selecting elbows. If you need more comprehensive and reasonable suggestions and product prices, please send us an email mtldsales@metleader.com