What products does the carbon steel flange supplier supply?

Carbon steel flange suppliers in China offer a diverse range of products to cater to the needs of various industries. These suppliers specialize in manufacturing and supplying high-quality carbon steel flanges that meet international standards and customer requirements. From standard flange types to custom designs, their product offerings are extensive and reliable.

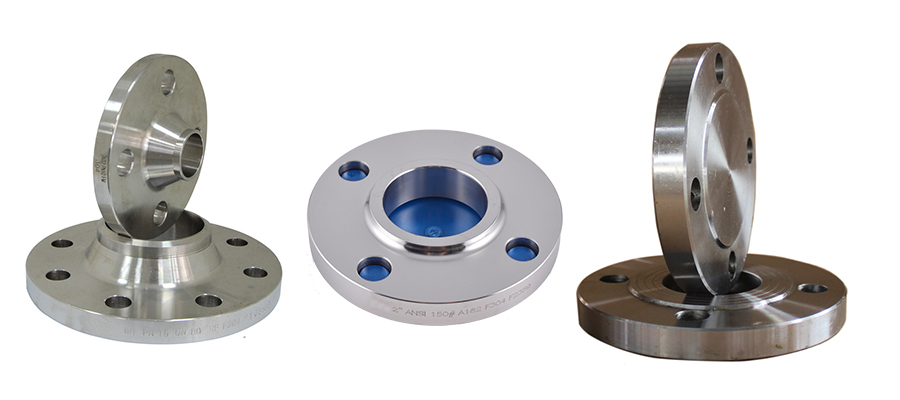

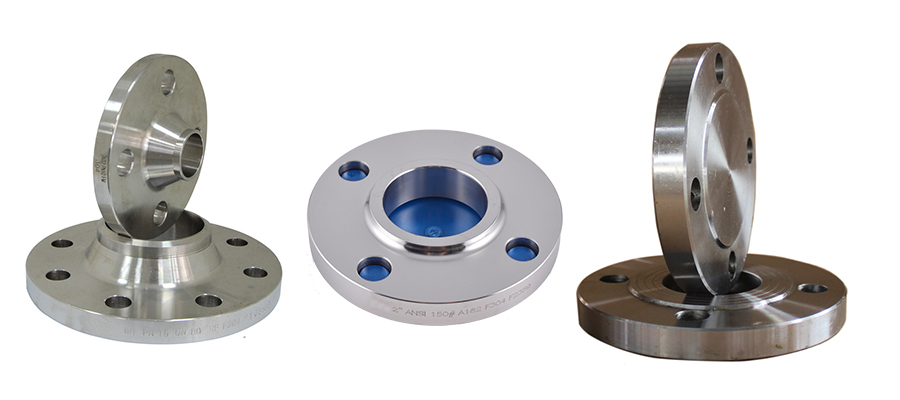

Weld Neck Flanges:

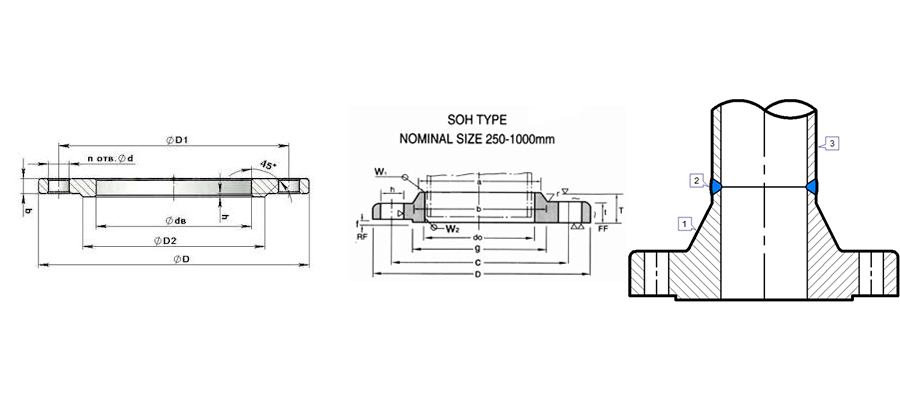

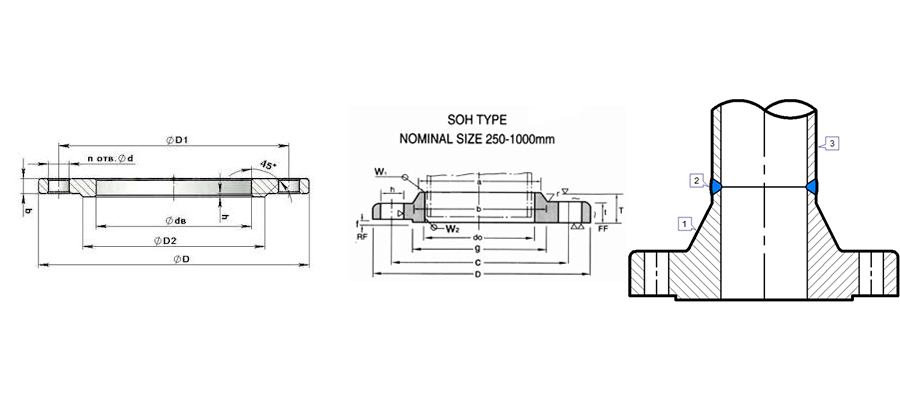

Weld neck flanges are one of the most commonly used types in piping systems. Carbon steel flange suppliers provide weld neck flanges in different sizes and pressure ratings. These flanges have a tapered hub and a circular weld neck, which offers excellent strength and durability.

Slip-On Flanges:

Slip-on flanges are easy to install and ideal for low-pressure applications. Carbon steel flange suppliers produce slip-on flanges with a raised face or a flat face, depending on customer specifications. These flanges are widely used in industries such as petrochemical, oil and gas, and water treatment.

Blind Flanges:

Blind flanges are used to seal the end of a pipe or vessel. Carbon steel flange suppliers offer blind flanges in various dimensions and configurations to suit different requirements. These flanges are crucial for isolation purposes, maintenance, and inspection of pipelines.

Threaded Flanges:

Threaded flanges provide a secure connection between pipes with threaded ends. Carbon steel flange suppliers manufacture threaded flanges with precision to ensure leak-free joints. These flanges are widely used in plumbing systems, fire protection, and small-bore pipelines.

Socket Weld Flanges:

Socket weld flanges are designed for small-bore piping systems where welding is preferred. These flanges have a socket-like shape that fits over the pipe and is welded on the outer side. Carbon steel flange suppliers offer socket weld flanges in various sizes and pressure ratings.

Chinese flange suppliers take the following measures to ensure the quality of flanges.

1. Strict selection of raw materials: Suppliers choose high-quality carbon steel materials as raw materials for flanges. This includes ensuring that materials comply with relevant international standards and code requirements, and conducting necessary chemical composition and mechanical performance tests.

2. Production process control: The supplier implements strict production process control to ensure the quality of the flange. This includes controlling the processing process, monitoring process parameters, implementing strict quality checks and tests, etc. Suppliers usually have modern production equipment and technology to ensure accurate machining and good surface treatment of flanges.

3. Quality inspection and testing: The supplier conducts various quality inspections and tests to verify the performance and quality of the flange. This may include dimensional checks, mechanical property testing (such as tensile and hardness testing), compression testing, etc. Suppliers are usually equipped with professional quality inspection equipment and laboratories to ensure that flanges comply with relevant standards and specifications.

4. Quality management system certification: Suppliers may pass international quality management system certification such as ISO 9001 to demonstrate that their quality management system complies with international standards. This certification demonstrates the supplier's ability to establish and maintain high quality standards.

5. Third-party inspection: Some suppliers may entrust an independent third-party organization to inspect and verify the flanges they produce. This provides an objective assessment and ensures that the flange meets predetermined standards.

6. Customer feedback and after-sales service: Suppliers actively pay attention to customer feedback and provide good after-sales service. They carefully analyze customers' opinions and suggestions, and take necessary corrective measures to improve product quality and meet customer needs.

2. Production process control: The supplier implements strict production process control to ensure the quality of the flange. This includes controlling the processing process, monitoring process parameters, implementing strict quality checks and tests, etc. Suppliers usually have modern production equipment and technology to ensure accurate machining and good surface treatment of flanges.

3. Quality inspection and testing: The supplier conducts various quality inspections and tests to verify the performance and quality of the flange. This may include dimensional checks, mechanical property testing (such as tensile and hardness testing), compression testing, etc. Suppliers are usually equipped with professional quality inspection equipment and laboratories to ensure that flanges comply with relevant standards and specifications.

4. Quality management system certification: Suppliers may pass international quality management system certification such as ISO 9001 to demonstrate that their quality management system complies with international standards. This certification demonstrates the supplier's ability to establish and maintain high quality standards.

5. Third-party inspection: Some suppliers may entrust an independent third-party organization to inspect and verify the flanges they produce. This provides an objective assessment and ensures that the flange meets predetermined standards.

6. Customer feedback and after-sales service: Suppliers actively pay attention to customer feedback and provide good after-sales service. They carefully analyze customers' opinions and suggestions, and take necessary corrective measures to improve product quality and meet customer needs.

Previous:How to determine the center of the 60 degree elbow center

Next:How to choose the right elbow in 11 elbow in projects ?

Next:How to choose the right elbow in 11 elbow in projects ?