What are the carbon steel butt welding pipe fittings?

Carbon steel butt weld fittings are a common pipe connection fitting used to connect carbon steel pipes.Here are some common carbon steel butt weld fittings:

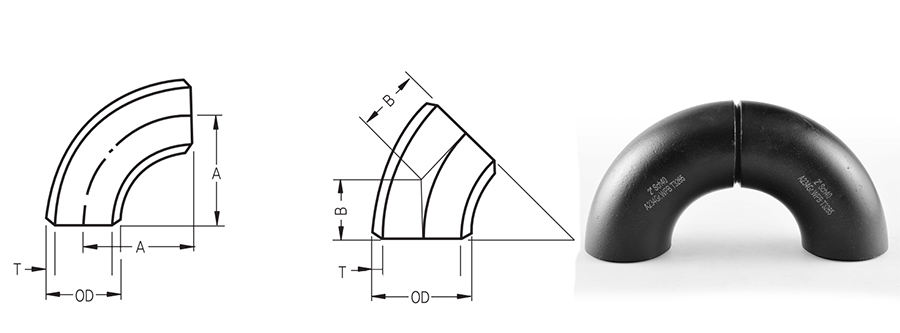

Elbow: It is used to change the flow direction of the pipeline, usually with 90-degree elbow and 45-degree elbow.Equal Tee: Used to divide the pipeline into three equal flow directions.

Reducer: Used to connect two pipes of different diameters, divided into the same diameter line reduction head (concentric reducer) and different diameter line reduction head (eccentric reducer).

Elbow Reducer: Combining the functions of elbow and line reduction, it can change the flow direction and diameter of the pipe.

Cap: Used to close the end of the pipe to prevent water leakage and entry of impurities.

These are just some common carbon steel butt welded pipe fittings. In fact, there are other types of pipe fittings, such as socket welded pipe fittings, reducing tees, cross joints, etc. You can choose the appropriate pipe fittings according to your specific pipeline needs.

5 reasons to choose carbon steel butt welding pipe fittings:

1.High strength: Carbon steel butt welding pipe fittings are made of high-strength carbon steel material, which has good strength and pressure resistance. They are able to withstand the demands of working in high pressure and high temperature environments.2.Good sealing performance: Butt welding pipe fittings are connected by butt welding, and the pipe connection fittings are connected with the pipe itself by welding to form a strong and reliable seal. This connection has good sealing performance and can prevent leakage problems.

3.Firm structure: Butt welded pipe fittings firmly connect the pipe connection fittings with the pipe itself by welding to form an integral structure. Compared with other connection methods, such as threaded connection, butt welding connection is stronger and can withstand greater pressure and vibration.

4.High fluid transmission efficiency: The inner wall surface of the butt welding pipe fittings is smooth, without raised threads or connecting parts, which reduces the frictional resistance of the fluid in the pipeline and improves the fluid transmission efficiency.

5.Easy installation and maintenance: Butt welding pipe fittings have standardized size and shape, and the installation process is relatively simple. In addition, because the butt welding connection is detachable, it is more convenient when repairing the pipeline or replacing the pipe fittings.

Generally speaking, carbon steel butt welded pipe fittings have the advantages of high strength, good sealing, firm structure, high fluid transmission efficiency, and convenient installation and maintenance, so they are widely used in many industrial fields.

Previous:china manufacturer forging stainless steel socket weld flange

Next:how to calculate the 60 degree elbow dimensions

Next:how to calculate the 60 degree elbow dimensions