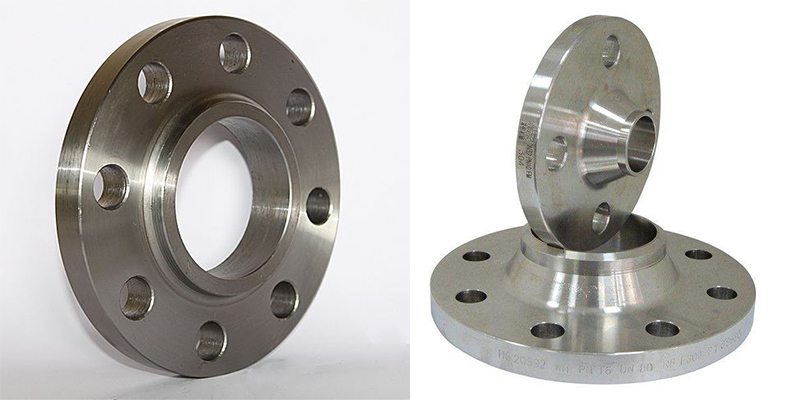

Welding method of flat welding flange and socket flange

Flat welding and socket welding are different. Socket welding flanges are suitable for small diameter, high pressure and high temperature pipeline connection methods.

Flat welding has a stepped sealing surface that acts as a compression gasket, and then the pipe is inserted into it for welding.

Socket welding means that there is no boss, and a groove is directly opened on the flange body, just like a hole is opened on a blind flange, and then a groove is opened.

Flat welding is slightly better than socket welding. Generally, flat welding flanges are used in general and can be used anywhere. Flange types are mainly butt welding, flat welding, socket welding, lap joint, thread, blind plate, etc., the pressure is above 4.0MPa and the use of flammable, explosive and toxic media is very good. Butt welding flanges are generally used in flat welding. Orchid.

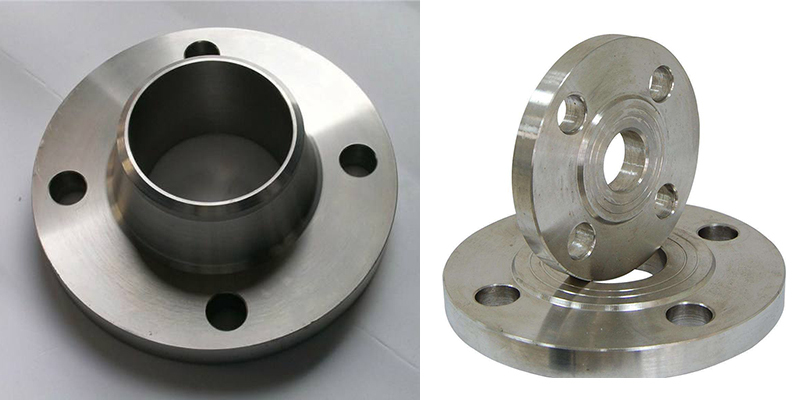

For flat welding flanges, the inner mouth of the flange is equivalent to the outer diameter of the pipe. The pipe is checked into the flange and the flange is welded. According to the situation, both inside and outside can be welded. Butt welding flange refers to the high and medium pressure flange with a neck, which is higher than the reverse side of the flange, and is provided for welding.

Flat welding and butt welding refer to the welding methods when flanges and pipes are connected:

1. When welding flat welding flanges, only one side welding is required, and there is no need to weld the inner port of the connection between the pipe and the flange. The welding device of the butt welding flange requires double-sided welding of the flange. Therefore, flat welding flanges are generally used for low and medium pressure pipelines.

2. Butt welding flanges are used for the connection of medium and high pressure pipelines. The butt welding flanges are generally at least PN2.5MPa. The butt welding is used to reduce stress concentration. The general butt welding flanges are mostly neck flanges. It's called a pacifier flange. Therefore, the installation cost, labor cost and auxiliary material cost of the butt welding flange are high, because there is one more process.

3. Not all butt welding flanges need to be welded on both sides. There are no special requirements. Generally, only one outer welding is required. Flat welding flanges are a better type of welding. not

Previous:Installation method of stainless steel flange

Next:Influence of technological factors of butt welding flange on welding seam formation

Next:Influence of technological factors of butt welding flange on welding seam formation