Installation method of stainless steel flange

The stainless steel flange is resistant to acid and alkali, anti-corrosion, and has a strong texture function. It is made of sub-oxygen furnace for cutting, and the overall forging or product forging and cutting are formed by high-precision CNC lathe turning and CNC radial drilling drilling. The connection method of stainless steel flange includes single-sided welding and double-sided nut connection. When welding, only single-sided welding is required without welding the inner port of the pipe and flange connection. It is generally used for low and medium pressure pipelines.

The sealing surface of the flange can be made into three types: smooth type, concave-convex type and tongue-and-groove type. Among them, the application of smooth flange is large, and it is mostly used in the case of relatively moderate medium conditions, such as low-pressure unpurified compressed air and low-pressure circulating water. When a crack in the flange occurs, the root of the crack must be analyzed. From the results of metallographic inspection, the grain of the material is coarse, which is caused by improper temperature control during casting or heat treatment.

Coarse grains will have some adverse effects on the mechanical properties of steel, such as the reduction of plasticity and toughness, especially the toughness of the material at low temperature. Therefore, during casting and heat treatment, necessary measures should also be taken to prevent coarse grains, and some trace elements can also be added to refine the grains, so as to achieve the purpose of improving the mechanical properties of steel. Therefore, the test of the metallographic structure is carried out, so that the correct cause of the welding crack can be analyzed.

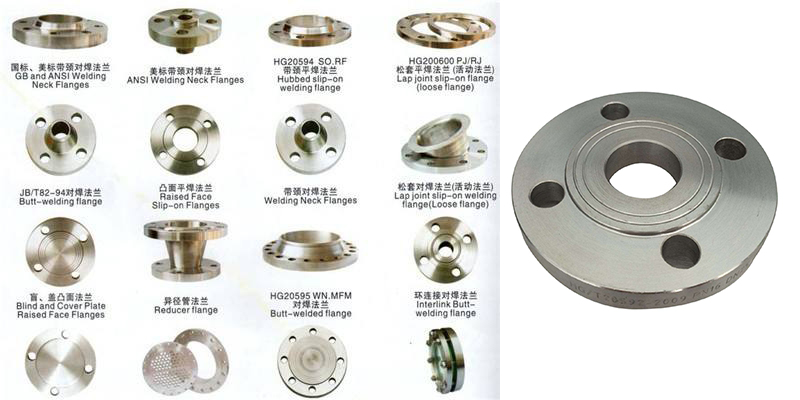

Flange is commonly known as flange, just a general term, generally refers to the opening of some fixed holes near an alloy body similar to a disk to connect other items.

Flange alias flange or flange. Parts that connect pipes to each other are connected to pipe ends. There are holes on the flanges, and the anchor bolts make the two flanges tightly connected. Gasket sealing between flanges. Flange is a kind of disc part, which is common in pipeline installation, and flanges are used in pairs. In pipeline installation, flanges are mainly suitable for the connection of pipelines.

Previous:Bending pipe production requirements and mechanical properties

Next:Welding method of flat welding flange and socket flange

Next:Welding method of flat welding flange and socket flange