3 ways to use stainless steel elbow

1. Bent tires are also one of the factors that affect the quality of bends. When we make bent tires, in addition to the specification and size requirements that are within the tolerance range, we also require users to select the corresponding bent tires according to the bent pipe diameter during service.

2. The buckling performance of the pipe itself and the appearance of corrosion may also affect the quality of the elbow. When starting the site, the operator also needs to understand the material, processing performance and appearance corrosion of the pipeline to be processed to make a production judgment.

3. When the tube is buckled, under the effect of the external force M, the outer arm wall of the inner layer becomes thinner under the effect of tensile stress, and the inner side is under compressive stress. Effective and thickened, the combined forces N1 and N2 make the cross section of the tube deformed. Based on this factor, the main reason for the decrease in the quality of the induced elbow is RX and SX. Therefore, in GBJ235-82, the RX value under various pressure levels and the amount of thinning on the outside are clearly specified. The goal is to control The values of RX and SX, therefore determine the quality.

4. As mentioned in the previous article, when the pipe is bent, the material is stretched on the outside and the neutral axis under pressure on the inside exists. The position of the neutral axis is different from the bending method. In the top bending (compression buckling) office, the neutral axis is about At 1/3, the neutral axis is at 2/3 away from the outer wall when turning the office. Because of the buckling of this thin-walled pipe, the active spin-bending method is beneficial.

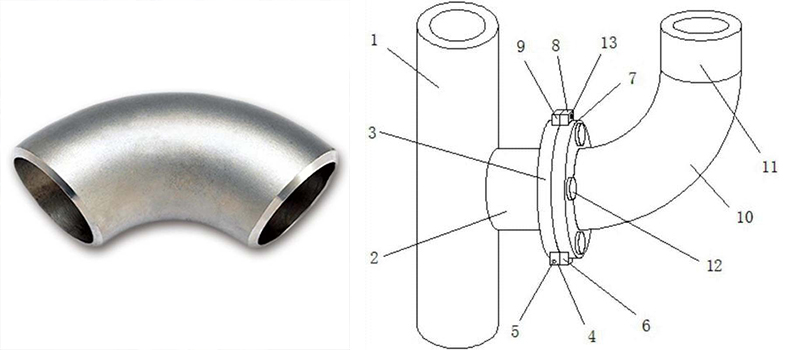

Stainless steel elbow is a forming process that has been used in mass production without seam elbows. At present, in the production of commonly used specifications of elbows, it has been replaced by hot push method or other forming processes. However, in some specifications of elbows, due to the small number of production, excessively thick or thin wall thickness, stainless steel elbows are formed. The method is still in use. The stamping and forming of the elbow adopts a tube blank with the same outer diameter as that of the elbow, and is directly pressed into a mold by a press. Before punching, the tube blank is placed on the lower mold, the inner core and the end mold are loaded into the tube blank, the upper mold moves downwards to start pressing, and the elbow is formed by the restraint of the outer mold and the support of the inner mold. Compared with the hot push process, the appearance quality of stamping forming is not as good as the former; the outer arc of the stamping elbow is in a stretched state during forming, and there is no excess metal in other parts to compensate, so the wall thickness at the outer arc is reduced by about 10% about. Due to its suitability for single-piece production and low cost, the stamping elbow process is mostly used in the manufacture of small batches and thick-walled elbows.

Previous:5 points for attention when processing stamping elbows

Next:Bending pipe production requirements and mechanical properties

Next:Bending pipe production requirements and mechanical properties