5 points for attention when processing stamping elbows

Pay attention to the following points when processing stamping elbows

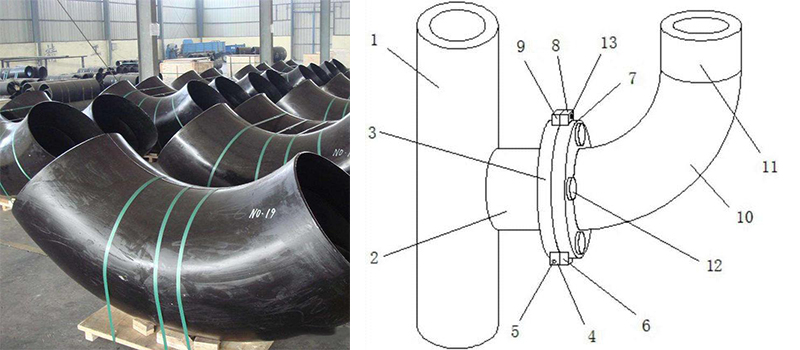

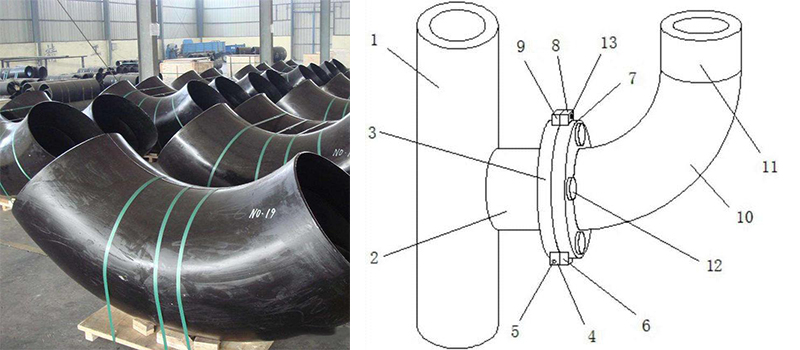

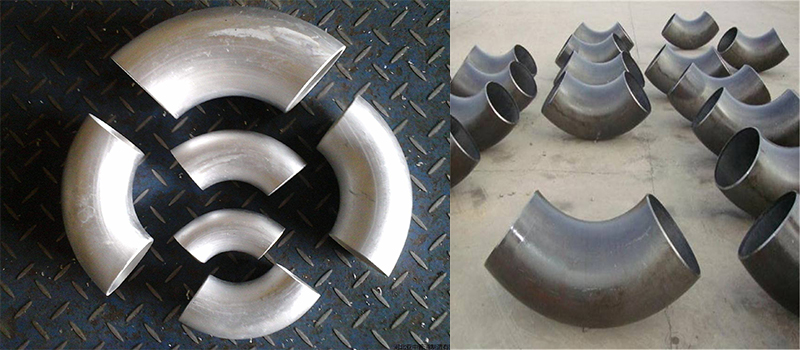

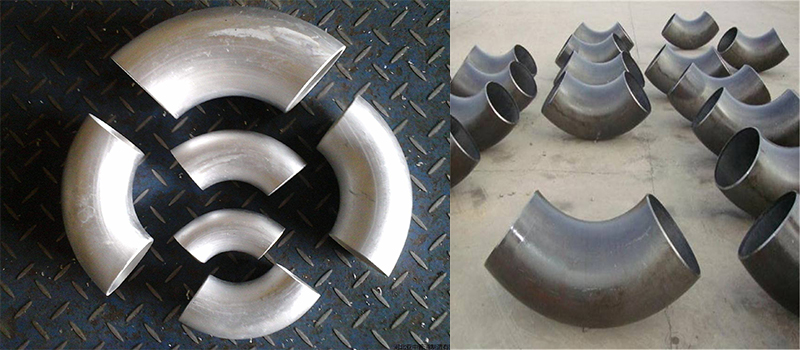

Stamping elbow is a very good elbow, which is widely used and promoted in different industries. The stamping elbow is a semi-circular elbow made of the same material as the pipe. Then weld the two half-circular elbows together. The welding of stamping elbows needs to be produced and processed in accordance with the procedures. Due to the different welding standards of various pipes, semi-finished products are generally solidified and produced according to group-to-point, and on-site construction is carried out according to the welding level of the pipe, so it is also called two semi-stamping elbows.

Matter 1

Stamping elbows have good corrosion and performance, and their good characteristics have prompted their use and promotion in different fields, and are widely used in chemical, fertilizer, petroleum, and machinery manufacturing.

Matter 2

Stamping elbow has corrosion resistance (oxidizing acid, acid, cavitation), heat resistance and energy. It is usually used for power station, chemical, petroleum and other equipment materials. The weldability of chromium stainless steel stamping elbows is poor. Attention should be paid to the welding process, heat treatment conditions and the selection of suitable welding rods.

Matter 3

Stamping elbow coatings are available in titanium calcium type and low hydrogen type. Titanium-calcium type can be used for AC and DC, but the penetration depth is relatively shallow during AC welding, and it is easy to be red, so the carbon steel elbow uses DC power as much as possible.

Matter 4

Stamping elbows have greater hardening after welding and are prone to cracks. When welding, different electrodes are used for welding, and the quality of the welded stamping elbows. If the same type of chrome stamping elbow electrode is used for welding, preheating above 300°C and slow cooling treatment at about 700°C after welding are carried out. If the weldment cannot be subjected to post-weld heat treatment, chromium-nickel stamping elbows should be used. Different types of welding rods have different performances and characteristics in use, and are selected according to the corresponding needs in use, and the quality of the welded stamping elbow.

Matter 5

Is the corrosion resistance and weldability of stamping elbows. Appropriate amount of stability elements Ti, Nb, Mo, etc. are added during production, and the weldability is better than that of chrome stamping elbows. When using the same type of chrome stainless steel stamping elbow, it should be preheated above 200℃ and tempered at about 800℃ after welding. If the weldment cannot be heat treated, the chrome-nickel stainless steel stamping elbow should be used.

Previous:Cold bending method and quality requirements of elbows

Next:3 ways to use stainless steel elbow

Next:3 ways to use stainless steel elbow