When do you use slip on flanges?

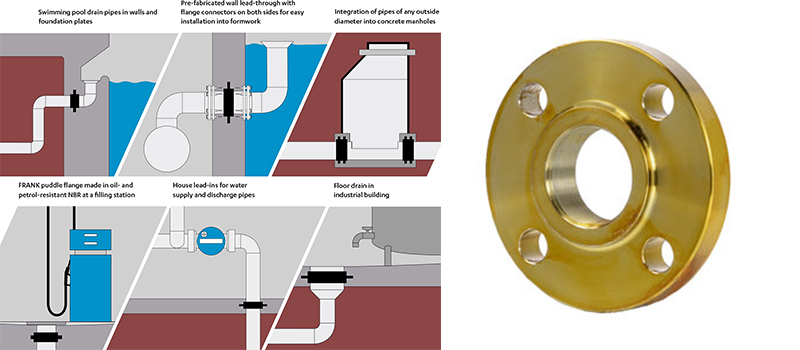

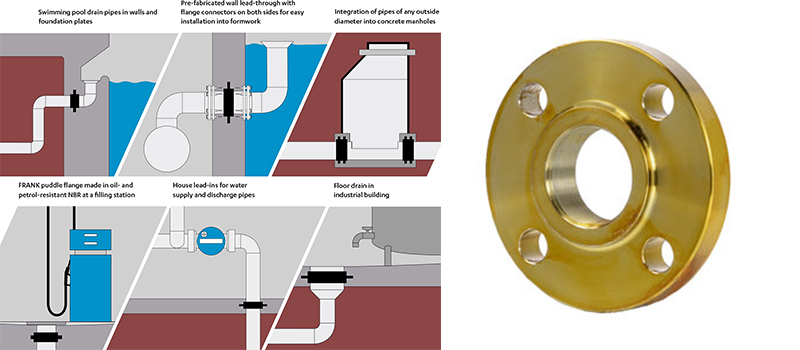

Slip on flanges is used to insert the pipe into the flange’s inner hole. Slip-on pipe flanges are used with a raised or flat face. Slip-On Flanges are a suitable choice for low-pressure applications. Slip on flange is excessively utilized in many fluid pipelines.

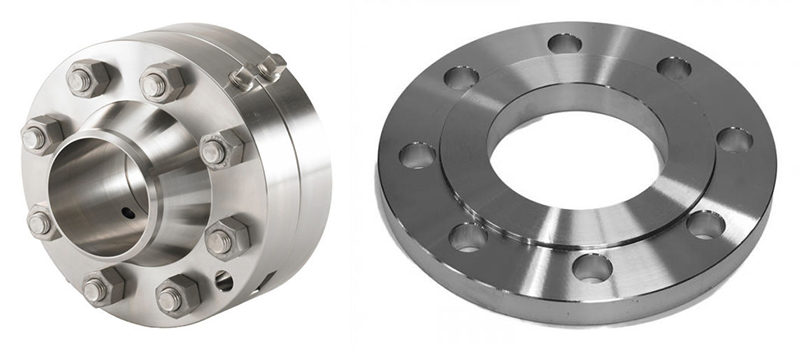

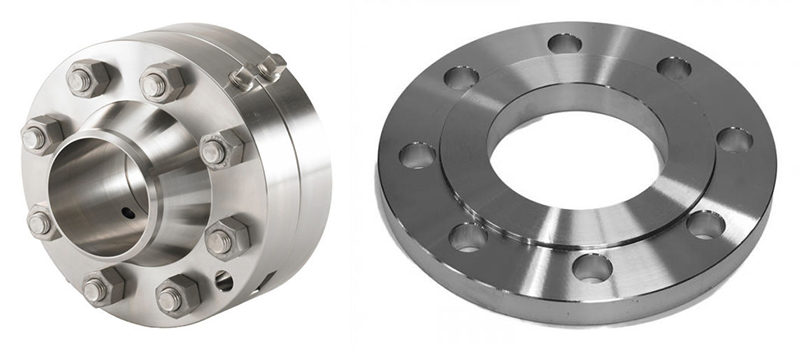

Slip on Flange Is fundamentally a ring placed over the end of the pipe, with a flange face extending from the end of the pipe by sufficient distance to apply a welded bead to the inner diameter. As the name suggests these flanges slip over a pipe and hence known as Slip On Flanges. A slip-on flange is also known as SO flange. It’s a kind of flange that are slightly bigger than the pipe and slides over the pipe, with internal design. Since the inner dimension of the flange is slightly bigger than the external dimension of the pipe, the top and bottom of the flange can be connected directly to equipment or pipe by fillet welding the SO flange.

The slip on flange may be attached to the end of a piece of pipe or to one or more ends of a pipe fitting. The slip-on flange is positioned so the inserted end of the pipe or fitting is set back or short of the flange face by the thickness of the pipe wall plus 1/8 of an inch. This allows for a fillet weld inside the SO flange equal to the thickness of the pipe wall without doing any damage to the flange face. The back or outside of the flange is also welded with a fillet weld.

Slip On Flanges are preferred by some contractors, over the Weld-neck, because of the lower initial cost. However, this may be offset by the added cost of the two fillet welds required for proper installation. The strength of the slip-on flange is ample for it’s rating, but its life under fatigue conditions is considered to be only one-third that of the weld-neck flange.

A variation of the Slip On flange also exists. This is the Slip-On Reducing Flange. This is simply a larger (say a 14″) Slip-On flange blank that, instead of the Center (pipe) hole being cut out (or drilled out) for 14″ pipe it is cut out for a 6″ (or some other size) pipe. The SO Reducing flange is basically used for reducing the line size where space limitations will not allow the length of a weld neck flange and reducer combination. The use of the Slip-On Reducing Flange should only be used where the flow direction is from the smaller size into the larger size.

Slip on Flange Is fundamentally a ring placed over the end of the pipe, with a flange face extending from the end of the pipe by sufficient distance to apply a welded bead to the inner diameter. As the name suggests these flanges slip over a pipe and hence known as Slip On Flanges. A slip-on flange is also known as SO flange. It’s a kind of flange that are slightly bigger than the pipe and slides over the pipe, with internal design. Since the inner dimension of the flange is slightly bigger than the external dimension of the pipe, the top and bottom of the flange can be connected directly to equipment or pipe by fillet welding the SO flange.

The slip on flange may be attached to the end of a piece of pipe or to one or more ends of a pipe fitting. The slip-on flange is positioned so the inserted end of the pipe or fitting is set back or short of the flange face by the thickness of the pipe wall plus 1/8 of an inch. This allows for a fillet weld inside the SO flange equal to the thickness of the pipe wall without doing any damage to the flange face. The back or outside of the flange is also welded with a fillet weld.

Slip On Flanges are preferred by some contractors, over the Weld-neck, because of the lower initial cost. However, this may be offset by the added cost of the two fillet welds required for proper installation. The strength of the slip-on flange is ample for it’s rating, but its life under fatigue conditions is considered to be only one-third that of the weld-neck flange.

A variation of the Slip On flange also exists. This is the Slip-On Reducing Flange. This is simply a larger (say a 14″) Slip-On flange blank that, instead of the Center (pipe) hole being cut out (or drilled out) for 14″ pipe it is cut out for a 6″ (or some other size) pipe. The SO Reducing flange is basically used for reducing the line size where space limitations will not allow the length of a weld neck flange and reducer combination. The use of the Slip-On Reducing Flange should only be used where the flow direction is from the smaller size into the larger size.

Previous:How do you calculate the length of an elbow?

Next:Cold bending method and quality requirements of elbows

Next:Cold bending method and quality requirements of elbows