How do you calculate the length of an elbow?

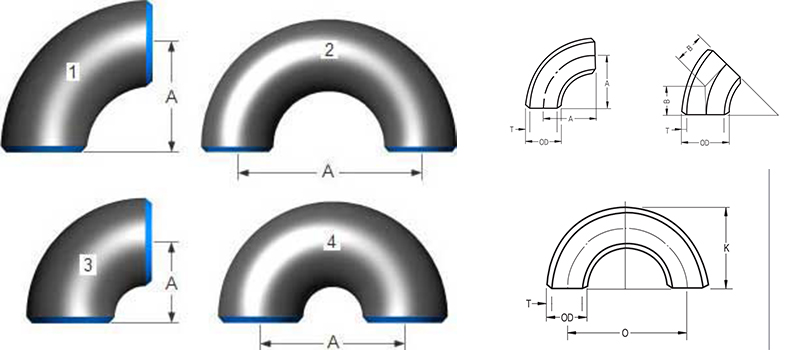

Elbows are split into two groups which define the distance over which they change direction; the center line of one end to the opposite face. This is known as the "center to face" distance and is equivalent to the radius through which the elbow is bent.

Here below, for example, you will find the center to face distance of NPS 2 elbows (the A distance on the image)

90°-LR : = 1½ x 2(NPS) x 25.4 A=76.2 mm

180°-LR : = 2 times the 90° LR elbow A=152.4 mm

90°-SR : = 2(NPS) x 25.4 A=50.8 mm

180°-SR : = 2 times the 90° SR elbow A=101.6 mm

The center to face distance for a "long" radius elbow, abbreviated LR always is "1½ x Nominal Pipe Size (NPS) (1½D)", while the center to face distance for a "short" radius elbow, abbreviated SR even is to nominal pipe size.

Measuring line size

Getting the line size is also fairly simple as it’s an easy measurement to take. All you need to do is measure the pipe or tube's outer diameter and wall thickness.

Tube sizes are typically whole number measurements such as two inches, three inches, and so on. Sometimes you may find a half-inch measurement or even a quarter-inch measurement, but this is rare in pneumatic conveying systems.

By measuring the wall thickness, you can then calculate the line size. If the wall thickness is 0.120 inches (11 gauge), 0.083 inches (14 gauge), or 0.065 inches (16 gauge), then your tubing or pipe material conforms to tube specifications. It's important to note that the term ‘pipe schedule’ references its wall thickness. Pipes usually have different wall thickness measurements which change according to the pipe size. A pipe schedule chart can help you figure out the pipe schedule by the wall thickness measurement.

guide-to-selecting-pneumatic-conveying-elbows

Finding the centerline radius

The more complex part of determining an elbow size is finding its centerline radius (the arc that goes down the center of the elbow). The centerline radius determines whether the elbow has a long arc, which makes it a long radius elbow, or a small arc which makes it a short radius elbow.

The height of the elbow is the centerline radius plus the tangent length, the tangent being the straight length of pipe that extends off the arc. This section of pipe can be used to install compression couplings on the elbow.

On standard-sized pneumatic conveying elbows, the tangent should be twice the nominal line size. For example, a two-inch elbow (pipe or tube) would have a four-inch tangent, a three-inch elbow (pipe or tube) would have a six-inch tangent, etc. Be warned that some sizes can be both a pipe and a tube size, but knowing this should get you close to a correct size.

Additionally, it’s important to note that the centerline radius usually occurs in one-foot increments. Common CLR’s are 12-inch, 24-inch, 36-inch, 48-inch, 60-inch, and 72-inch.

Calculating a 90-degree elbow - an example

Let’s say we have a normal 90-degree elbow in our pneumatic conveying system. The outer diameter of the elbow measures three inches, which means we probably have a tube elbow. The tube wall thickness is about an eighth of an inch thick, so we have an 11-gauge elbow.

Knowing all of this and using the above tangent rule, we can calculate that we have approximately six-inch tangents on each side of the elbow. Standing the elbow on one end, we measure from the center of the end of the elbow to the ground - it measures 42 inches.

Since the height of a 90-degree elbow is the centerline radius plus the tangent length, that means we have a 36-inch centerline radius elbow (42 inches – 6 inches = 36 inches).

And that's it! We have a three-inch outer diameter, 11-gauge, 90-degree, 36-inch centerline radius tube elbow.