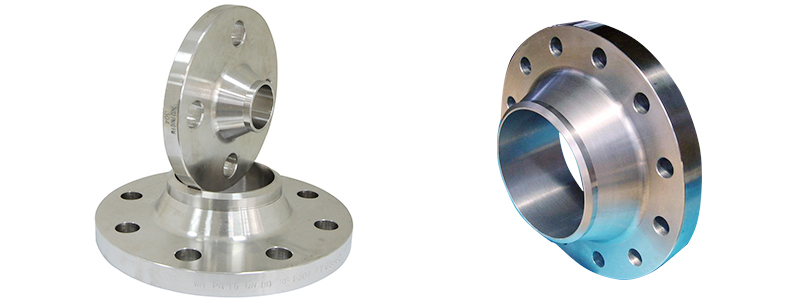

Butt-welding flanges are generally made by forging or forging-rolling technology. When steel plate or section steel is used for manufacturing, the following requirements must be met: butt welding flanges should be ultrasonically inspected without delamination defects; they should be cut into strips along the rolling direction of the steel, and be bent but welded into a ring, and the steel The surface forms the cylinder of the ring. The steel plate shall not be directly machined into a butt-welded flange with neck;

Installation of butt welding flange:

1. First, position the connector.2. Install the sealing ring, the inside of the sealing sleeve and the cone hole of the socket.

3. Install the ferrule, apply grease to the contact part of the ferrule and the cone of the ferrule for easy installation.

4. To install bolts and spherical nuts, grease should be applied to the spherical surface and threads for installation.

5. Tighten the nut must be tightened in a diagonal order gradually and evenly and ensure that the ferrule has a symmetrical position.

6. A torque wrench should be used to tighten the nut according to the required torque in the product manual.

The outer slope of the neck of the butt-welded flange should not be greater than 70. The butt welding flange strictly controls the technical parameters during production and welding to ensure that it can fully play its role and value in production and use.