Disadvantages and advantages of different flange connection (II)

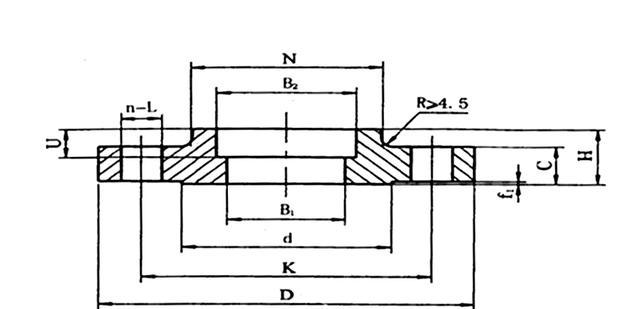

Socket weld flange connection:Socket weld flange connection is a flange with one end welded to the steel pipe and the other end bolted together.

Sealing surface: RF, MFM, TG, RJ

Application: boiler and pressure vessel, petroleum, chemical industry, shipbuilding, pharmacy, metallurgy, machinery, stamping elbow food and other industries.It is often used in the pipe of PN 10.0mpa and DN 40.

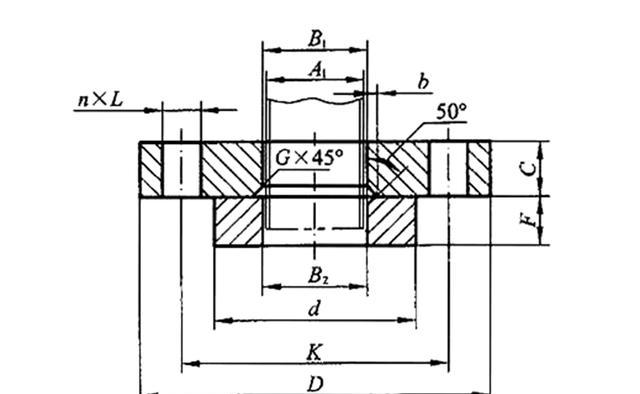

Thread flange connection:

The thread flange connection is a kind of non-welded flange, which processes the inner hole of the flange into pipe thread and connects it with the pipe with thread.

The threaded flange is a kind of non-welded flange, which processes the inner hole of the flange into pipe thread and connects it with the pipe with thread.Compared with plate or weld neck flange connections, thread flange connection is easy to install and maintain and can be used in some pipelines where welding is not allowed on site. Alloy steel flange has enough strength, but not easy to weld, or welding performance is not good, which can also choose thread flange connection. But in the pipe temperature changes or sharply temperature higher than 260 ℃ below - 45 ℃ under the condition of thread flange connection is not recommended, so as to avoid leakage.

Advantages: compared with plate or weld neck flange connections, thread flange connection is easy to install and maintain and can be used in some pipelines where welding is not allowed on site. Alloy steel flange has enough strength, but not easy to weld, or welding performance is not good, which can also choose thread flange connection.

Weakness: the pipe temperature changes or temperature sharply higher than 260 ℃ below - 45 ℃ under the condition of thread flange connection is not recommended, so as to avoid leakage.

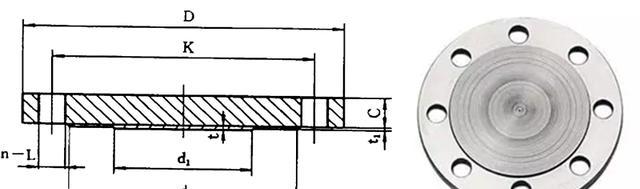

Blind flange connection:

It is a flange without hole in the middle for sealing the pipe. The function is same as that of the weld pipe cap and the thread cap, except that the blind flange and the thread cap can be removed at any time, while the weld pipe cap is not.

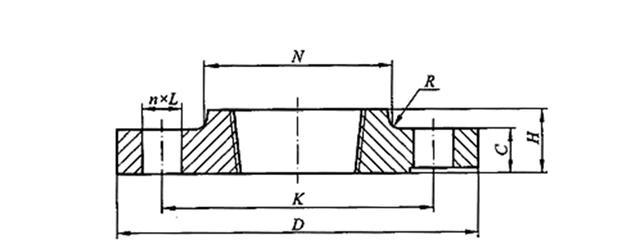

Lap joint flange connection:

Lap joint flange connection has two types, one is lap joint flange with butt welding ting the other one is lap joint flange with flat welding ring.

No matter with butt welding ting and flat welding ring, the purposeissave material, the structure is divided into two parts, one end of the pipe is connected to the pipe, and the other end is made into welding ring. The flange is made of low grade material, while the pipe part is made of the same material as the pipe, so as to save materials.

Advantages: cost saving, convenient construction.

Weakness: low pressure, low strength at the welding ring (especially when the thickness is less than 3mm)

Previous:Comparision between blind flange and pipe cap

Next:3PE anti-corrosion steel pipe spray mark

Next:3PE anti-corrosion steel pipe spray mark