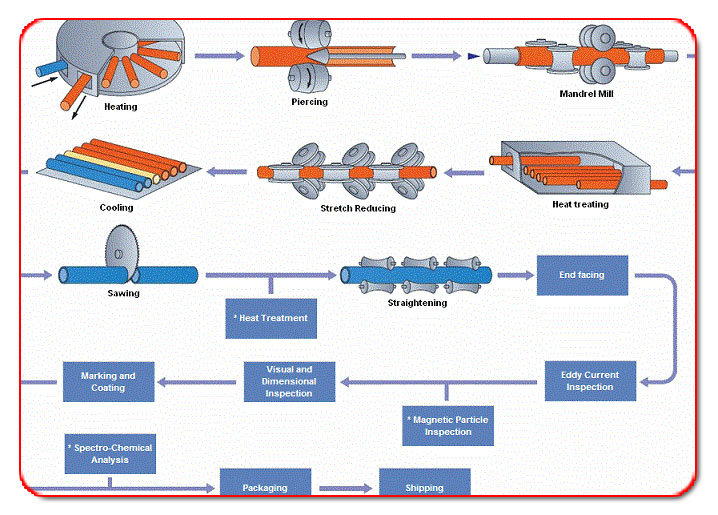

Heat treatment during the production of steel pipe

What is heat treatment of steel pipes?Heat treatment of steel pipes is a way toreleasethe stress and improve the mechanical properties of metal material. There are four main heat treatment methods for carbon steel and alloy steel pipes: normalizing, annealing, quenching and tempering. Heat treatment can improve the mechanical properties, uniform chemical composition and machinability of steel materials. The heat treatment of steel and metal materials can be divided into integral heat treatment, surface heat treatment and chemical heat treatment.Steel pipe generally adopts integral heat treatment.

The purpose of heat treatment.

The properties of steel mainly depend on mechanical properties, physicalpropertiesand technological properties.Heat treatment will bring different metallurgical structure and corresponding properties to the steel pipe, so it can be better applied to different industries or oil and gas services. There are two ways to improve the properties of steel. One way is to adjust the chemical composition, called alloying. Another method is heat treatment.In the field of modern industrial technology, heat treatment has improved the performance of steel pipes in a dominant position.

What is the procedure of heat treatment?

1. Heating.

The steel material can be heated below or above the critical point. The former heating method can stabilize the structure andeliminatethe residual stress. The latter method allows the material to be austenitized. Austenitizing is heating the steel metal at its critical temperature for long enough so that the transformation can occur. If hardening is carried out after austenitizing, the material will harden. Quenching needs to be fast enough to convert austenite to martensite.Once the austenitizing temperature, suitable microstructure and full hardness are achieved, the steel pipes material will be obtained during further heat treatment.

2. Heat preservation.

The purpose of heat preservation is to make the steel heating temperatureuniform, and then get a reasonable heating structure.

3. The cooling

Cooling process is the key process of heat treatment, which determines the mechanical properties of the steel tube after cooling process.

About the four heat treatment ways for carbon steel and alloy steel pipes. The heat treatment process of steel pipe includes normalizing, annealing, tempering,quenchingand other processes.

Normalizing:

The steel pipe is heated above the critical temperature and cooled in air. By normalizing, the stress of steel can be reduced and the ductility and toughness of cold processing can be improved. Normalizing is usually applied to carbon and low alloy steel pipe materials.It produces different metal structures, pearlite, bainite, some martensite. Compared to fully annealed materials, it results in harder, stronger steel with less ductility.

Annealing:

The material is heated long enough above its critical temperature until the microstructure becomes austenitic. It is then cooled slowly in the furnace to maximize the transformation of ferrite and pearlite. Annealing will eliminate defects so that the chemical composition and fine particlesareuniform.This process is usually suitable for high carbon, low alloy and alloy steel tubes, requiring reduction of hardness and strength, refinement of crystal structure, improvement of plasticity, ductility, toughness and machinability.

Quenching

The steel pipe material is heated to the critical temperature until the microstructure transformation is carried out for rapid cooling.

The purpose of quenching is to produce thermal stress and microstructure stress. It can be eliminated and improved by tempering.The combination of quenching and tempering can improve the comprehensive performance.

Tempering

To heat steel to an exact temperature below the critical point, usually in air, vacuum, or an inert atmosphere.Has a low temperature tempering from 205 to 595 ° F (400-1105 ° F), the moderate high temperature tempering (700 ℃, 1300 ℉).

The purpose of tempering is to increase the toughness of steel and alloy steel tubes. Before tempering, the steel isveryhard, but too brittle for most applications.The process can improve the ductility and toughness of steel pipe, reduce or eliminate residual stress, and stabilize the size of steel pipe. It has good comprehensive mechanical properties, so it will not change the service life.

Solid solution treatment of alloy base steel pipe

Solution treatment

Heat the alloy to a suitable temperature, keep it at that temperature long enough for the composition or more to become a solid solution, and then cool it quickly to keep the composition in solution.

Thereare a variety of casting and forging nickel-based alloys, which can achieve different desired properties through solid solution treatment or precipitation aging hardening.Through this heat treatment, the mechanical strength, corrosion resistance, oxidation resistance and other properties of room temperature and high temperature can be significantly improved. Many nickel-based alloys develop their required properties only by solid solution treatment (such as hastelloy and nickel alloy steel pipes).

During the solid solution treatment, carbides and alloying elements are uniformly dissolved in the austenite. Rapid cooling will cause carbon and alloying elements to precipitate too late and obtain a single austenitic structure during the heat treatment process. Solid solution treatment canmakeinternal structure and chemical composition even. It can also restore the corrosion resistance of hastelloy and nickel alloy steel pipes.