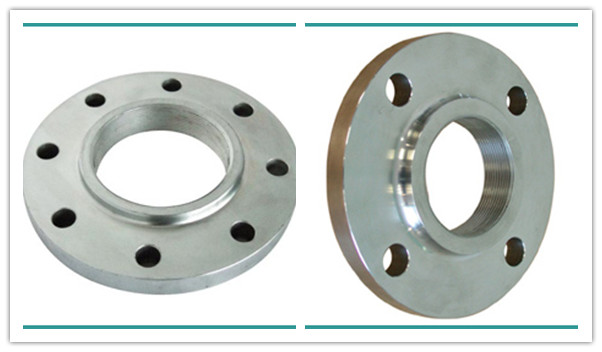

Threaded Flange

Home > Products > Flanges > DIN Flange > Threaded Flange

Threaded Flange DIN2565 PN6

SPECIFICATIONS

Material: carbon steel/stainless Steel

Size: 1/2 "-24" and customized according to customer requirements

Connection: Thread

Manufacturing Way: Forging

Surface: Rust-Proof Oil, Black, Yellow, Galvanized

Transport Package: Standard Export Seaworthy Package

Trademark:Metleader

Origin: China

The thread flange is a kind of non welded flange, which is made into pipe thread by the inner hole of flange and connected with threaded pipe.

Slip on flange and welding flange have the features of easy installation, maintenance compared with the screwed flange, but some sites do not allow welding in pipeline, so thread flange can be used in these conditions. And alloy steel flange has enough strength, but difficult to weld, or welding performance is not good, such conditions threaded flange also can be chosen.

But in the case of a sharp change in the temperature of the pipe or the temperature is more than 260 ℃ below 45 ℃, it is not recommended to use threaded flanges to avoid leakage.

Threaded flanges look very similar to Slip-On flanges but the main difference is that the threaded flange has been was bored out to match a specific pipe inside diameter. The backside of this center opening is then threaded with the relevant-sized tapered pipe thread.

Threaded Flanges can be used in very high pressure services and their major advantage is that they can be assembled without welding.

We also have another flanges:

| Rated Diameter |

d1 | Flange | Neck | Raised face |

Screws | Weight of a flange (7,85 Kg/dm3) |

|||||||

| Thread | D | b | k | h1 | d3 | d4 | f | Number | Thread | d2 | Kg | ||

| 15 | 21,3 | R 1/2 | 80 | 12 | 55 | 20 | 30 | 40 | 2 | 4 | M 10 | 11 | 0,373 |

| 20 | 26,9 | R 3/4 | 90 | 14 | 65 | 24 | 40 | 50 | 2 | 4 | M 10 | 11 | 0,59 |

| 25 | 33,7 | R 1 | 100 | 14 | 75 | 24 | 50 | 60 | 2 | 4 | M 10 | 11 | 0,743 |

| 32 | 42,4 | R 1 1/4 | 120 | 14 | 90 | 26 | 60 | 70 | 2 | 4 | M 12 | 14 | 1,05 |

| 40 | 48,3 | R 1 1/2 | 130 | 14 | 100 | 26 | 70 | 80 | 3 | 4 | M 12 | 14 | 1,2 |

| 50 | 60,3 | R 2 | 140 | 14 | 110 | 28 | 80 | 90 | 3 | 4 | M 12 | 14 | 1,37 |

| 65 | 76,1 | R 2 1/2 | 160 | 14 | 130 | 32 | 100 | 110 | 3 | 4 | M 12 | 14 | 1,92 |

| 80 | 88,9 | R 3 | 190 | 16 | 150 | 34 | 110 | 128 | 3 | 4 | M 16 | 18 | 2,82 |

| 100 | 114,3 | R 4 | 210 | 16 | 170 | 38 | 130 | 148 | 3 | 4 | M 16 | 18 | 3,19 |

| 125 | 139,7 | R 5 | 240 | 18 | 200 | 40 | 160 | 178 | 3 | 8 | M 16 | 18 | 4,47 |

| 150 | 165,1 | R 6 | 265 | 18 | 225 | 44 | 185 | 202 | 3 | 8 | M 16 | 18 | 5,3 |