Customized products

Epoxy polyethylene anticorrosive steel pipe

SPECIFICATIONS

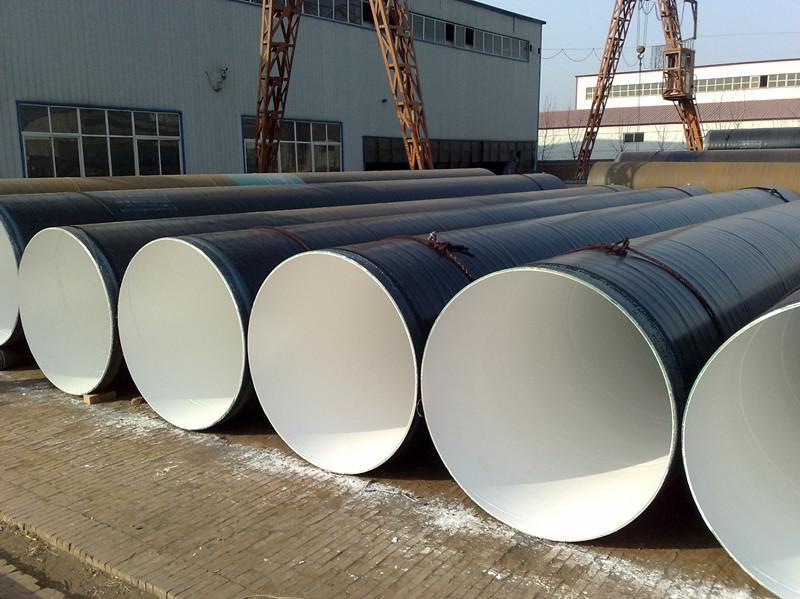

Epoxy polyethylene anticorrosive steel pipe

The inner and outer epoxy polyethylene anticorrosive steel pipe is a new type of steel-plastic composite pipe, which is composed of a steel pipe substrate, an epoxy resin inner coating and a polyethylene outer coating, and has excellent mechanical properties and corrosion resistance and aging resistance. Widely used in water conservancy, electric power, chemical, petroleum and many other industries. The connection method and requirements of the plastic coated composite pipe are as follows: firstly, the flange is welded at both ends of the steel pipe, and the flange should be welded firmly and then coated with polyethylene. When installing, install a gasket between the two flanges of the coated composite pipe, and press it with bolts to ensure that the pipe will not be axially moved under the action of pressure or water hammer, and it should be fixed, such as Piers, brackets, hangers, etc. When fixing, it should be considered that the pipe will not be displaced when the phenomenon of oscillation and deflection under pressure is generated. For vertically installed pipes, the spacing between the two fixed points should be no more than 2m.

When installing horizontally, the spacing between the two fixed points is: when the nominal outer diameter of the coated composite pipe is less than 76mm, it should be no more than 750mm; when the nominal outer diameter of the coated composite pipe is not less than 76mm, it should be no more than 1100mm. When fixed by cement or brick buttress, the pipe can be built into the buttress. When brackets, brackets, and hangers are used for fixing, it is necessary to provide a U-shaped or other type of pipe clamp in the pipe. Since the surface of the pipe is smooth, in order to prevent the pipe card from slipping, a rubber pad is placed between the pipe surface and the pipe clamp, and the pipe clamp is tightened with a screw to prevent it from sliding, and then the pipe clamp is passed through bolts and the like, the support pier, the bracket and the bracket. Wait for the connection to be firm. It can also be installed according to the user's drawings. When the construction drawings cannot be provided, it can be sent to the site for measurement. The user can design and manufacture special pipe joints to connect with the mining pipe or connect with the seamless steel pipe through the quick pipe clamp. When installing the pipeline, the warning line on the pipe must be kept facing outward to form a line to show safety warning.