Customized products

Thick 90 Degree Carbon Steel Short Radius Elbow

SPECIFICATIONS

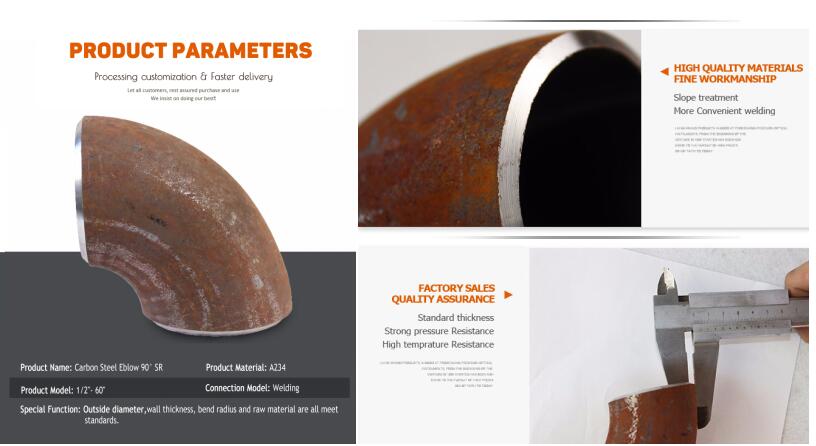

Thick 90 degree carbon steel short radius elbow

Thick 90 degree carbon steel short radius elbow with the continuous development of high-voltage industry, more and more industries and enterprises to use the high-pressure elbow, for some operators stand out, such as Beijing Metleader Pipeline Technology inc is a professional production of Thick 90 degree carbon steel short radius elbow, high-pressure elbow, duplex steel high-pressure elbow, 16MN high-pressure elbow, stainless steel high-pressure elbow, Boiler high-pressure elbow, alloy high-pressure elbow products such as the collection of industry and trade in one spot manufacturer, and perennial preparation of various models of spot inventory. More than 36years manufacturing experience, we always adhere to the development of high-pressure elbow, mold production, production process, sales, after-sales service consistency operations. In the high-pressure pipe fittings market to brew a good quality and reputation.Products have been exported to the United States, Southeast Asia and other countries.

Thick 90 degree carbon steel short radius elbow forming process is the use of special elbow push machine, core mold and heating device, so that the stock in the mold in the push forward movement of the machine, in motion by heating, expanding and bending the process of forming. The deformation characteristic of the hot push elbow is to determine the diameter of the tube billet according to the invariable volume of the plastic material before and after deformation. The Tube billet diameter is smaller than the elbow diameter, through the core mold control blank deformation process, so that the internal arc compressed metal flow, compensation to the expansion of the other parts of the thinning, so as to obtain a uniform wall thickness elbow.

The hot push elbow forming process has the appearance, the wall thickness uniformity and the continuous operation, is suitable for the mass production characteristic, thus becomes the carbon steel, the alloy steel elbow main forming method, and also applies in certain specification stainless steel elbow's forming. The heating mode of the forming process is medium frequency or high frequency induction heating (the heating coil can be multiple or one lap), flame heating and reflective furnace heating, and the heating mode is decided by the forming product requirements and the energy situation. Stamping forming elbow is * early used in mass production seamless elbow forming process, in the common specifications of elbow production has been a hot push or other forming technology replaced, but in some specifications of the elbow due to the production of small quantities, thick or too thin wall.

Products are still in use when they have special requirements. Thick 90 degree carbon steel short radius elbow can be connected directly to the pipe and installed according to the position used. However, the open section with curved pipe, only to consider the cost, bending pipe need to hot simmer, bending pipe cold bend can, of course, is the high cost of bending pipe. Carbon steel is not only good in plasticity and weldability, but also has high strength, hardness and good abrasion resistance. Therefore, the high-pressure alloy elbow in power plants, electric power, concrete pump transportation and many other industries have a wide range of applications.

If you need carbon steel elbow ,welcome you send me email: sales@metleader.com