Customized products

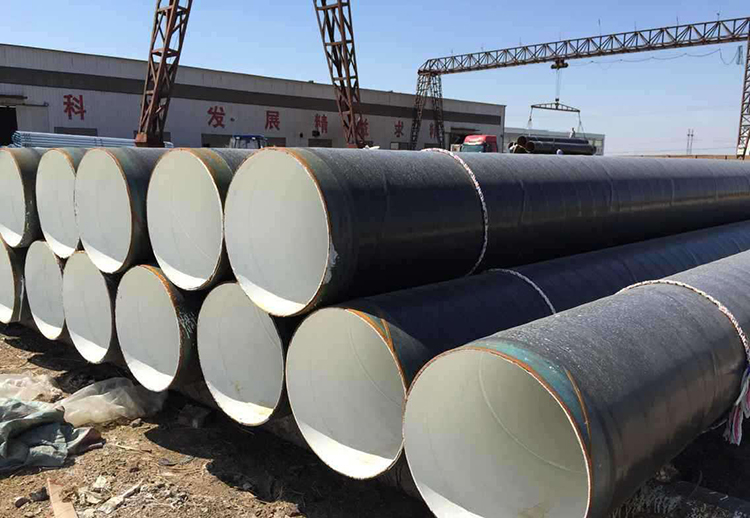

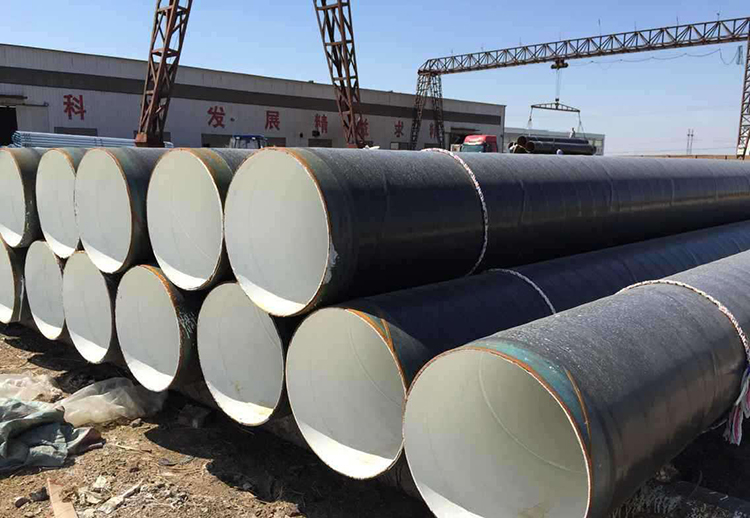

Anti-Corrosion Pipe

SPECIFICATIONS

Anti-Corrosion Pipe

High-pressure natural gas anti-corrosion pipeline 3pe anti-corrosion pipe base includes seamless steel tube, spiral steel pipe and straight seam pipe. The three-layer polyethylene (3PE) anti-corrosive coating has been widely used in the petroleum pipeline industry for its good corrosion resistance, water vapor permeability and mechanical properties. 3PE anti-corrosion pipe for the life of buried pipelines is critical, the same material pipeline, some buried in the ground for decades without corrosion, some years on the leak. Because they use different kinds of outer coating.

Main equipment of Anti-corrosion pipe for high pressure natural gas: steel tube cushion Platform, Dial tube unit, Traction machine, pipe-piercing machinery, high-pressure gun machine, repair platform, transmission line, steel tube preheating furnace, shot blasting machine mainframe overhaul and the difference lattice steel pipe return transmission line, Fast forward roller group, quick out wheel, overhaul platform. Anti-corrosion production line of anti-corrosion pipe can be applied to single layer fbe, Double-layer fbe, double layer PE, double layer pp and 3PE anti-corrosion operation. The smallest processing pipe diameter φ104mm (4"), the biggest processing diameter φ1600mm (63"), the maximum processing capacity 350m2/h above, the production line includes steel pipe transmission system, surface treatment system, pipe body dust removal system, pipe heating system, electrostatic spraying system, coating system, water cooling system.

End-cutting system, hydraulic and pneumatic systems, testing systems and electronic control systems. 3PE anti-corrosion pipe has good insulation performance, heat loss is only 25% of the traditional pipe, long-term operation or can save more resources, obviously reduce energy costs, and still have a relatively strong waterproof and corrosion resistance, and do not need to have a trench, directly can be buried underground or water, In the construction is also simple and rapid, comprehensive cost is also relatively low, at low temperature also has good corrosion resistance and impact resistance, and in a certain environment can also be directly buried in the frozen soil.

Three-layer structure polyethylene anti-corrosion layer (3PE) of anti-corrosion steel tube composite epoxy coating and extruded polyethylene Two kinds of anti-corrosion layer of excellent properties, the interfacial characteristics and chemical resistance of epoxy coating were combined with the mechanical protection characteristics of extruded polyethylene anti-corrosion layer, which improved the performance of them remarkably. Therefore, as the outer protective layer of the buried pipeline is very advantageous, at present it is considered as the most advanced anti-corrosion technology of pipeline outside the world. 3PE anti-corrosion pipe in line with the "good anti-corrosion Effect" "non-polluting" "solvent-free" "Energy", "economic" good principle. Its structure principle is: The bottom is the fusion knot epoxy, the middle layer is the adhesive, the surface layer is the extruded polyethylene. Its characteristics are high strength, corrosion resistance, acid, alkali, salt, long service life.