Customized products

Welded steel pipe and seamless steel pipe

SPECIFICATIONS

Welded steel pipe and seamless steel pipe

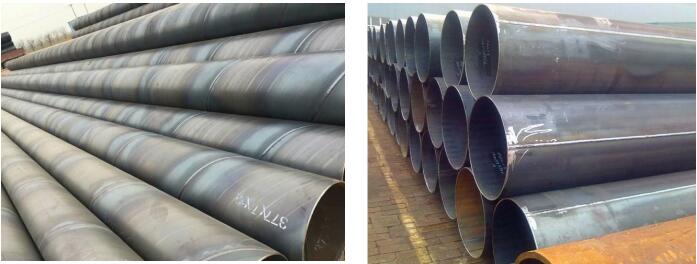

The welded steel pipes.The raw material used for welded steel pipe is steel plate or strip steel. Welded steel pipes can be divided into furnace-welded pipe, electric-welded pipe (ERW) and automatic submerged arc welded pipe because of its different welding technology. It can be divided into longitudinal welded pipe and spiral welded pipe.

Seamless steel pipes.

Because of its different manufacturing technology, it can be divided into hot rolled (extruded) seamless steel pipe and cold drawn seamless steel pipe. Cold drawing (rolling) pipe can be divided into round pipe and special shape pipe.

With the development of industrial applications evolve and become more complex, the pipeline products and systems that serve them must keep pace.

Although there are many pipe manufacturing methods existing, the most prominent discussion in the industry is welded steel pipes manufactured with ERW and seamless (SMLS) steel pipes.

ERW steel pipes and seamless steel pipes manufacturing methods have been used for decades; Over time, the two methods all have been improved some. However, which manufacturing processing is better?

The manufacturing process of welded steel pipes.

The welded steel pipes began as a long, coiled strip of steel known as skelp. The skelp should be cut into designed lengths to obtain flat rectangular steel plate.The shorter end of the steel plate becomes the outer circumference of the pipe, and this value can be used to calculate its final outside diameter.

Steel plate are went through a rolling machine that curls the long edges toward each other to form a cylinder. In the ERW process, high-frequency currents pass between the edges, causing them to melt and fuse together.

One advantage of ERW steel pipes is that they do not use molten metal and cannot see weld seam.This is in contrast to double submerged arc welding (DSAW), which leaves obvious weld seam that must be wiped off according to application. Over the years, welded steel pipe manufacturing process has been improved a lot. Maybe the most important progress was to adopt high frequency electricity for welding. Before the 1970s, low-frequency electricity were used. But ERW with low frequency electricity are more easily corrosion and welding failure. Most of welded steel pipe required heat treatment after production.

The manufacturing process of seamless steel pipes.

The seamless steel pipes manufactured with a solid cylindrical steel block called a billet.By heating the billet and pierced them through the mandrel .The next step is to roll and stretch the hollow billet. The billet is precisely rolled and stretched until it reached to the length, diameter and wall thickness requested by the customer.

Some seamless steel pipes don’t need heat treatment because they are heated during manufacturing. However, for some special material seamless pipe heat treatment is necessary.

The comparison between welded steel pipes and seamless steel pipes

Generally, welded steel pipes are considered inherently weak because the weld seams. Seamless steel pipes lack this perceived structural flaw and are considered more safety. Although welded steel pipes do include weld seams that make them theoretically weaker, however the manufacturing techniques and quality assurance have been greatly improved. While the advantages of seamless steel pipes are obvious, the disadvantage of seamless steel pipe is that the rolling and stretching processes produce inconsistent wall thickness compared to the more precise plate thickness used for welded steel pipes.

These views are still reflected in the development and standardization of ERW and seamless steel pipe industry standards. For example, many high-pressure and high-temperature applications in the oil and gas, power generation and pharmaceutical industries require seamless steel pipes. As long as temperature, pressure and other service variables do not exceed the parameters specified in the applicable standards, welded steel pipes can be specified in all industries (usually with low production costs and widespread use). There is no difference in the performance between ERW and seamless steel pipes in structural application. They can be specified each other but when welded steel pipes have same good working performance with more cheaper cost, there is no necessary to adopt seamless steel pipes.