What is the use of slip on flanges?

Sliding on the flange is preferred by some contractors in the slip on because of the lower initial cost. However, this can be offset by the additional cost of the two fillet welds required for proper installation. The strength of the slip-on flange is adequate for its rating, but its fatigued state of life is considered to be only one third of the slip on flange.

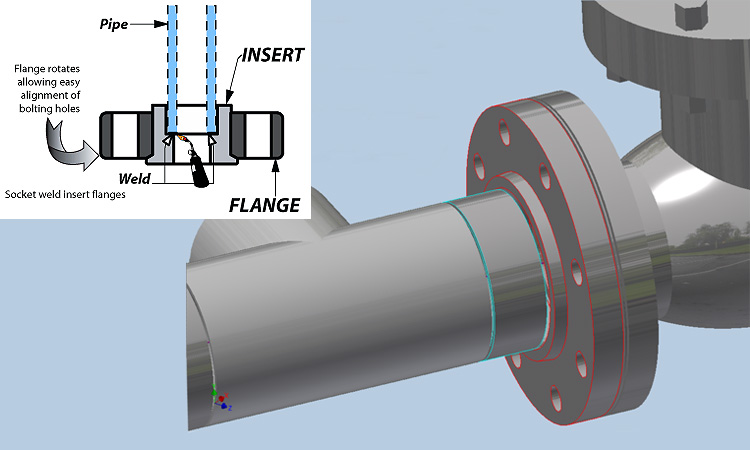

The upper flange slip may be attached to the end of one or more ends in a tube or fitting. The slide-on flange is positioned so that the insertion end of the tube or the tube is set back or short flanged by 1/8 of the thickness of the tube wall. This allows the flange SO to equal the thickness of the pipe wall without any damaging internal fillet weld of the flange face. Flange welds are also welded on the back or outside of the flange.

Changes in sliding flanges also exist. This is a sliding flange reduction. This is just a larger (say 14 ") slide-mounted flange blank, instead of the center (tube) hole being cut (or drilled out) for the 14" tube to be cut out 6" (or some other The size of the tubing. The SO reduction flange is basically used to reduce the size of the circuit, where the space limitation will not allow the welded neck flange and the combined length of the reduction. Should only be used to reduce the flow of the flange in the sliding sleeve type. The direction is from a smaller size to a larger size.

The slip flange or SO flange is usually lower in price than the welded neck flange, and this effect is a popular choice for customers.

Its interior and exterior welded to provide suffcient strength and prevent leakage.

Slip flanges are boring slightly larger than the outside diameter of the tube. They are superior to the welding neck flange BU many users due to their lower cost INTIAL, but the final cost of installing the paper probably does not exceed, due to the far less welding welded flange involved.

Advantage slip on flange:

Low installation cost

Less time is needed to ensure cutting accuracy

They are easier to align and the upper flange has a lower hub because the pipe slips into the flange before welding

Flange welding provides sufficient strength both inside and outside

They prevent leaks