Ansi socket weld flange dimensions

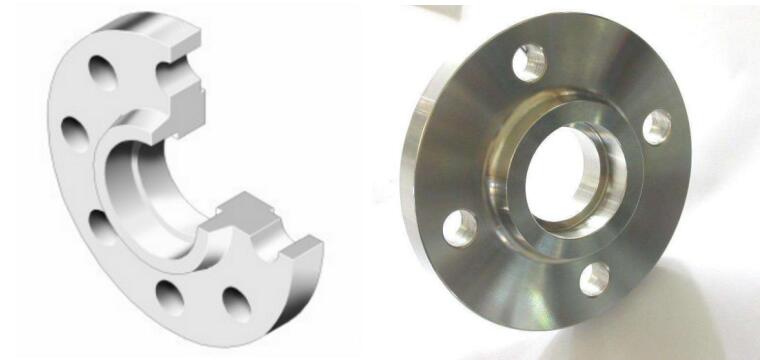

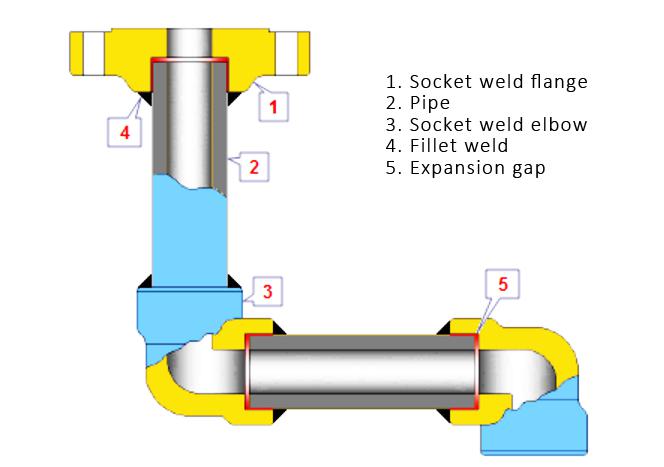

Socket weld flange (SW) is similar to slip on flange, but there is only one fillet weld between the flange and the pipe. Insert the pipe into the socket and support the pipe between 1/16 "to 1/8" and weld the pipe to the socket welding flange. This is to prevent the expansion of the expansion tube inside the weld during welding and to crack the weld.

There are several different ways to ensure that there is enough clearance in the weld. The first is to insert the pipe fully into the flange and mark the pipe. Then remove the pipe and move the mark 1/16 "to 1/8" and weld it.

Another approach is to use tools called gaps. The clearance is an elastic gasket mounted between the pipe and the flange. Clearance should be considered when designing piping systems. The reason for this is that over time the gaps may fall off the flange and move downstream toward the flange.

Socket weld flange is originally designed for small diameter high pressure pipe.The flange has FF (flat face), RF( raised face) and a RTJ connection. The socket weld flange that conformed to ANSI B16.5 only applies to the pipelines pressure below 10.0 Mpa and dimension less than DN80.

ANSI socket weld flange dimensions 150 class 1/2” to 3” as following:

|

Nominal |

Outside |

Thickness |

Raised Face |

Length |

Hub |

Bore |

Bore |

Depth |

Approximate |

Bolt |

Number |

Diameter |

|

(O) |

(T) |

(R) |

(Y) |

(X) |

(B1) |

(B2) |

(D) |

(lbs) |

(C) |

|||

|

1/2 |

3.50 |

0.44 |

1.38 |

0.63 |

1.19 |

0.62 |

0.88 |

0.38 |

1 |

2.38 |

4 |

0.63 |

|

3/4 |

3.88 |

0.50 |

1.69 |

0.63 |

1.50 |

0.82 |

1.09 |

0.44 |

2 |

2.75 |

4 |

0.63 |

|

1 |

4.25 |

0.56 |

2.00 |

0.69 |

1.94 |

1.05 |

1.36 |

0.50 |

2 |

3.13 |

4 |

0.63 |

|

1 1/4 |

4.63 |

0.63 |

2.50 |

0.81 |

2.31 |

1.38 |

1.70 |

0.56 |

3 |

3.50 |

4 |

0.63 |

|

1 1/2 |

5.00 |

0.69 |

2.88 |

0.88 |

2.56 |

1.61 |

1.95 |

0.63 |

3 |

3.88 |

4 |

0.63 |

|

2 |

6.00 |

0.75 |

3.63 |

1.00 |

3.06 |

2.07 |

2.44 |

0.69 |

5 |

4.75 |

4 |

0.75 |

|

2 1/2 |

7.00 |

0.88 |

4.13 |

1.13 |

3.56 |

2.47 |

2.94 |

0.75 |

7 |

5.50 |

4 |

0.75 |

|

3 |

7.50 |

0.94 |

5.00 |

1.19 |

4.25 |

3.07 |

3.57 |

0.81 |

8 |

6.00 |

4 |

0.75 |

The above information is just only about socket weld flange 150 class, for other data sheet please contact us through email sales@metleader.com. Know more us please send me email sales@metleader.com

Socket Weld flanges not only advantages but also have disadvantages:

1. No slant welding preparation is required. No temporary location welding is required on time. Because the accessories in principle ensure the correct alignment.

2. The weld metal shall not penetrate the inner hole of the pipe.

They can be used instead of threaded joints, so the risk of leakage is much smaller. Radiography is not practical for fillet weld; Therefore correct welding and welding are of vital importance. You can check the fillet weld. Through surface inspection, magnetic powder (MP) or liquid penetrant (PT) inspection method.

4. Due to the lack of strict assembly requirements, the construction cost is lower than the welding joint. Cancel the special processing for the docking end.

Next:What is weld neck flange 300#?