Galvanized Reducing Tee

We are a factory who export galvanized reducing tee to oversee countries. What we always insist on is the stable quality. From material to finished products, our process are strictly produced according to the ISO and CE requirements.

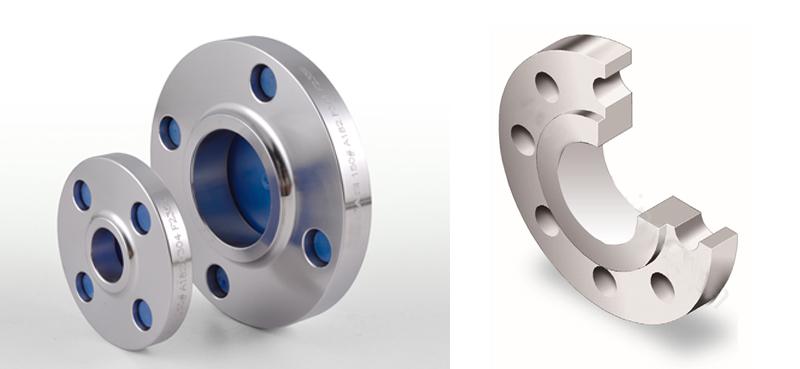

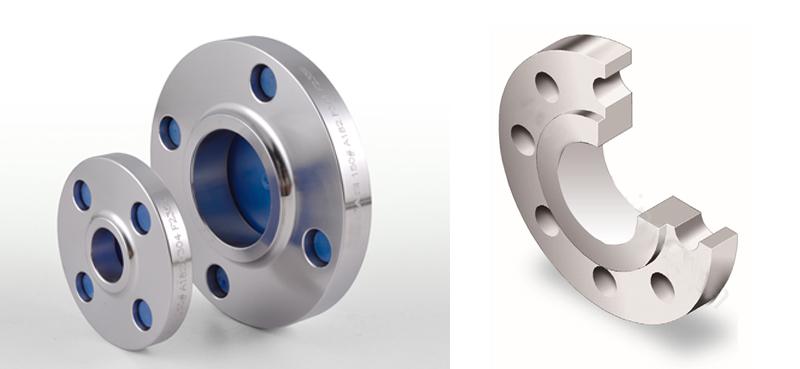

Galvanized reducing tee for the treatment of galvanized pipe, galvanized reducing tee including galvanized elbow, galvanized pipe, galvanized flange, galvanized pipe, galvanized tube cap head. Galvanized galvanized coating thick, with a uniform coating, strong adhesion, long service life, and other advantages. A complex physical and chemical reaction is formed between the tube matrix and the molten plating solution, which forms a close zinc-iron alloy layer with corrosion-resistant structure. The alloy layer is integrated with the pure zinc layer and the pipe fitting matrix.

Galvanized reducing tee are mainly used for conveying gas, heating and other pipeline projects, if the pipe body needs to be galvanized anti-corrosion treatment, the corresponding connection pipe will also be galvanized treatment. Therefore, its corrosion resistance is strong. The cost of electroplating zinc is low, the surface is not very smooth, its own corrosion resistance of specific heat galvanized pipe a lot of difference. The main purpose of galvanizing is to enhance the corrosion resistance of the pipe.

The main production flow of hot galvanized reducing tee:

Degreasing → rinsing → pickling → cleaning → dipping help plating agent → hot air drying → hot Dip galvanizing → inside and outside blowing → cooling → passivation and rinsing.

Methods for checking galvanized reducing tee:

1.Look at the thickness, wall thickness evenly reached the standard thickness, wall thickness is less than the required wall thickness of 0.875.

2.The size of the structure, the size of the national standard requirements.

3.The appearance of smooth, no burr, galvanized even beautiful.

Galvanized reducing tee for the treatment of galvanized pipe, galvanized reducing tee including galvanized elbow, galvanized pipe, galvanized flange, galvanized pipe, galvanized tube cap head. Galvanized galvanized coating thick, with a uniform coating, strong adhesion, long service life, and other advantages. A complex physical and chemical reaction is formed between the tube matrix and the molten plating solution, which forms a close zinc-iron alloy layer with corrosion-resistant structure. The alloy layer is integrated with the pure zinc layer and the pipe fitting matrix.

Galvanized reducing tee are mainly used for conveying gas, heating and other pipeline projects, if the pipe body needs to be galvanized anti-corrosion treatment, the corresponding connection pipe will also be galvanized treatment. Therefore, its corrosion resistance is strong. The cost of electroplating zinc is low, the surface is not very smooth, its own corrosion resistance of specific heat galvanized pipe a lot of difference. The main purpose of galvanizing is to enhance the corrosion resistance of the pipe.

The main production flow of hot galvanized reducing tee:

Degreasing → rinsing → pickling → cleaning → dipping help plating agent → hot air drying → hot Dip galvanizing → inside and outside blowing → cooling → passivation and rinsing.

Methods for checking galvanized reducing tee:

1.Look at the thickness, wall thickness evenly reached the standard thickness, wall thickness is less than the required wall thickness of 0.875.

2.The size of the structure, the size of the national standard requirements.

3.The appearance of smooth, no burr, galvanized even beautiful.