How to Made Flanges

Flange is a strategy for connecting or connecting pipes, valves, pumps and other equipment to form a piping system. It also provides simple cleaning, checking or adjustment. The flange is usually welded or threaded. Flange joints are made by connecting two flanges with gasket bolts to form a seal.

The flange is a forged or thrown steel ring used to connect the pipe portion or connect the pipe to the pressure weight, pump or any other basic flange. By darting the flange and connecting to the pipe frame by welding or thread.

The basic type of flange is; Slip on, blind, welded neck, thread, socket welding, lap joint and orifice plate.

Flange design conforms to the following pressure level; 150 pounds, 300 pounds, 400 pounds, 600 pounds, 900 pounds, 1,500 pounds and 2500 pounds.

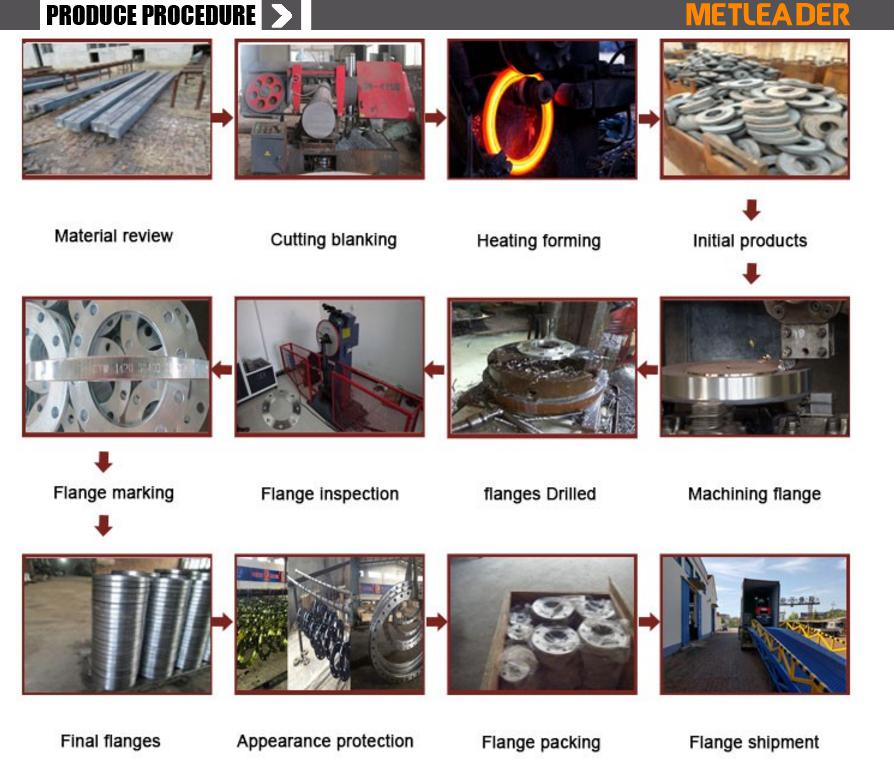

But how to made flanges?

The production processing of flange mainly is divided into forging, casting, cutting and rolling.

Forged flanges usually have a lower carbon content than the casting flange and do not rust easily. They have smooth streamline, internal tissue uniformity and better mechanical properties than foundry flanges. There are no defects, such as pores and cracks in the cast flanges. Compared with the casting flange, the forged flange can withstand the higher shearing force and pulling force. However, if the use of incorrect forging process, but also cause large uneven grain and solidification cracking phenomenon, resulting in a higher cost than the casting flange. Please see the following production processing drawing of flange.

The inspection of flange is very important which directly guarantee the quality is good of flanges that deliveried out. Generally our flange are inspected strictly according to the request of ISO, and CE system. All inspection datas of each chain are recorded carefully. So choosing us is just choosing safety.