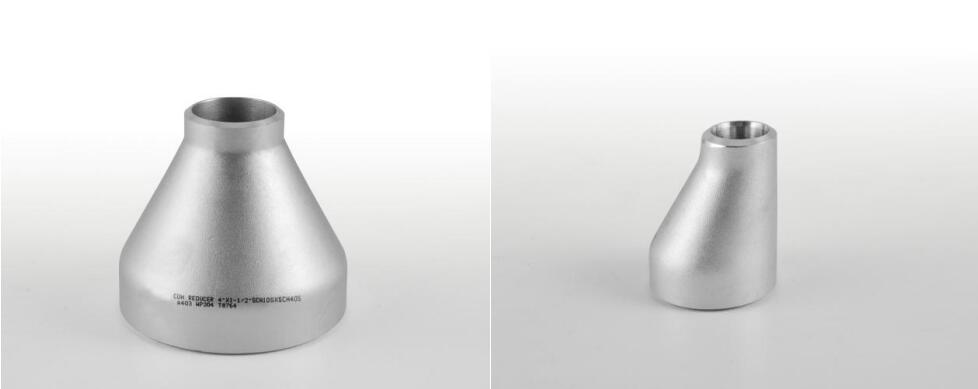

Definition and application of stainless steel pipe Concentric reducer and eccentric reducer

The stainless steel pipe reducer is often used in industry, mainly to connect the piping system. In a lot of places we will use it, but because the reducer is divided into concentric and eccentric, then we should make clear in the application of what they are different, their respective and inferior, so that in the application we will make the right choice and use more smooth. What is the eccentric reducer and concentric reducer? How can eccentric reducer and concentric reducer be used? Let's take a look at it here.

1. What is eccentric reducer and concentric reducer?

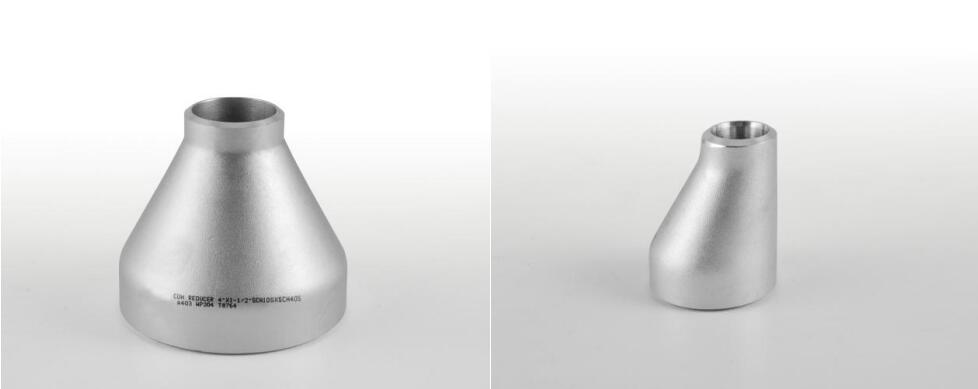

Reducer is also called the size of the head, used to connect the different sizes of the tube, generally it is divided into eccentric reducer and concentric reducer. Eccentric reducer refers to a different diameter tube which is not in the same line as the center. Its role is to wall or paste the pipeline without taking up space, and is connected to two different caliber pipe, change the size of the flow. The diameter tube of the center in the same line is called concentric reducer. The forming process is usually used for reducing the compression, expanding the diameter or reducing the diameter and expanding the diameter, and some specifications of the reducer can also be used stamping forming.

2.1) How to apply eccentric reducer:

The diameter of the pipe orifice at both ends of the eccentric reducer is used for connecting pipes or flanges of different diameters. Eccentric reducer at both ends of the tube mouth, the center of the same axis, when the diameter, the axis of the tube position, the position of the pipe is unchanged, generally used for gas or vertical liquid pipe diameter. Eccentric reducer at both ends of the tube orifice circumference, generally used for horizontal liquid piping. Eccentric reducer pipe mouth tangent point upward, known as the top-level installation, generally used for pump entrance, conducive to exhaust, the tangent point downward become the bottom of the installation, generally used for regulating valve installation, use of PAI net. The eccentric reducer is advantageous to the fluid flow, the disturbance of the fluid flow state is less when the diameter is changed, so the gas and the vertical liquid pipeline use concentric reducer to change diameter. The eccentric size head is flat on one side, is advantageous to the exhaust or the draining fluid, facilitates the drive and the overhaul, therefore the horizontal installation liquid pipeline generally uses the eccentric reducer tube.

2).How to apply concentric reducer:

Concentric reducer does not produce corrosion, pitting, rusting or abrasion. Can play a good role and performance in the industry. Concentric reducer in a certain industry and field to show the important role and performance, in the use of the display of certain and characteristics, concentric reducer or building materials in a high strength material. Concentric reducer resistant to air, steam, water and other weak corrosive medium and acid, alkali, corrosion of corrosive steels such as salt. Also known as stainless acid-resistant steel. In practical applications, steel, which is often corroded by weak corrosive medium, is called concentric reducer, and steel, which is corrosion resistant to chemical medium, is called acid-resisting steel because of the difference of chemical constituents between them, The former is not necessarily resistant to chemical media corrosion, while the latter generally have a rust-proof.

After detailed introduction of eccentric reducer and concentric reducer, we should clearly understand their main differences. Because they have their own specific attributes and characteristics, will be applied in different places, play their big role. Knowing this, in the future when we use the reducer, the heart will know how to choose.

1. What is eccentric reducer and concentric reducer?

Reducer is also called the size of the head, used to connect the different sizes of the tube, generally it is divided into eccentric reducer and concentric reducer. Eccentric reducer refers to a different diameter tube which is not in the same line as the center. Its role is to wall or paste the pipeline without taking up space, and is connected to two different caliber pipe, change the size of the flow. The diameter tube of the center in the same line is called concentric reducer. The forming process is usually used for reducing the compression, expanding the diameter or reducing the diameter and expanding the diameter, and some specifications of the reducer can also be used stamping forming.

2.1) How to apply eccentric reducer:

The diameter of the pipe orifice at both ends of the eccentric reducer is used for connecting pipes or flanges of different diameters. Eccentric reducer at both ends of the tube mouth, the center of the same axis, when the diameter, the axis of the tube position, the position of the pipe is unchanged, generally used for gas or vertical liquid pipe diameter. Eccentric reducer at both ends of the tube orifice circumference, generally used for horizontal liquid piping. Eccentric reducer pipe mouth tangent point upward, known as the top-level installation, generally used for pump entrance, conducive to exhaust, the tangent point downward become the bottom of the installation, generally used for regulating valve installation, use of PAI net. The eccentric reducer is advantageous to the fluid flow, the disturbance of the fluid flow state is less when the diameter is changed, so the gas and the vertical liquid pipeline use concentric reducer to change diameter. The eccentric size head is flat on one side, is advantageous to the exhaust or the draining fluid, facilitates the drive and the overhaul, therefore the horizontal installation liquid pipeline generally uses the eccentric reducer tube.

2).How to apply concentric reducer:

Concentric reducer does not produce corrosion, pitting, rusting or abrasion. Can play a good role and performance in the industry. Concentric reducer in a certain industry and field to show the important role and performance, in the use of the display of certain and characteristics, concentric reducer or building materials in a high strength material. Concentric reducer resistant to air, steam, water and other weak corrosive medium and acid, alkali, corrosion of corrosive steels such as salt. Also known as stainless acid-resistant steel. In practical applications, steel, which is often corroded by weak corrosive medium, is called concentric reducer, and steel, which is corrosion resistant to chemical medium, is called acid-resisting steel because of the difference of chemical constituents between them, The former is not necessarily resistant to chemical media corrosion, while the latter generally have a rust-proof.

After detailed introduction of eccentric reducer and concentric reducer, we should clearly understand their main differences. Because they have their own specific attributes and characteristics, will be applied in different places, play their big role. Knowing this, in the future when we use the reducer, the heart will know how to choose.

Previous:Characteristics and application of steel reducing tee

Next:How to maintain Stainless steel threaded flange

Next:How to maintain Stainless steel threaded flange