How do you calculate eccentric reducer offset?

The amount of offset in an eccentric reducer is defined as this formula:

A concentric reducer is used in pipe racks to maintain a constant bottom of pipe (BOP). Pipe supports within a pipe rack have the same elevation, so the piping system should have a consistent BOP to rest on each support.

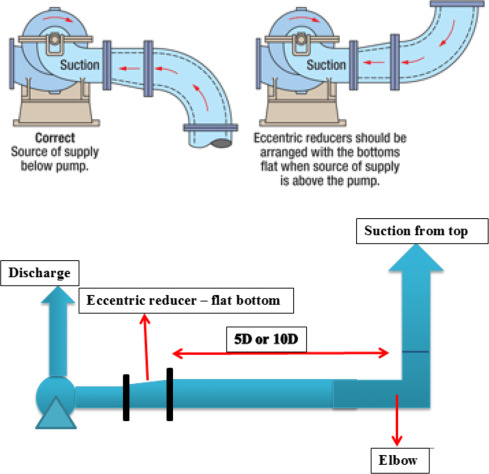

An eccentric reducer is used upstream of pumps to increase the fluid velocity and provide a net positive suction head. A reducer is also installed upstream and downstream of pressure safety valves (PSVs) in flare lines. The other application of an eccentric reducer is to increase the line size to 4″ for thermowell (temperature gauge) installation. An eccentric reducer does not change the bottom of the pipe and support height. Fig. 14.29 shows how to put the reducer before the pump.

The short length of a reducer probably does not allow enough space to have a thread or socket on both ends. Swages are longer than reducers. Swages, like reducers, are in both eccentric and concentric types. Swages can have three types endings—socket, thread, and beveled end on both sides . Swages are also called swage nipples.

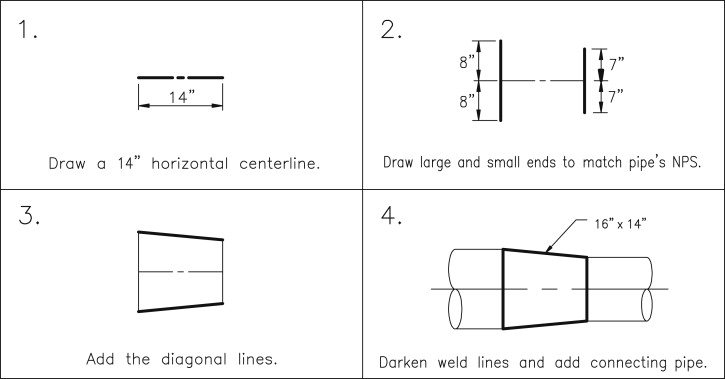

Drawing the Reducers

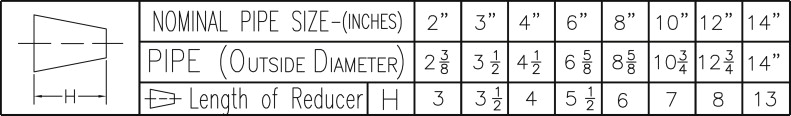

Before drawing the reducer, the length of the fitting must be found on the Welded Fittings–Flanges Dimensioning Chart . The H dimension will provide the end-to-end length for either the concentric or eccentric reducer.

Step 1. Using the H dimension found on the Welded Fittings–Flanges Dimensioning Chart, draw a centerline 14″ long.

Step 2. Measure 8″ (one-half the 16″ large end size) on each side of the centerline on one end of the centerline and 7″ (one-half the 14″ small end size) on each side of the opposite end of the centerline.

Step 3. Connect the opposing ends of the fitting by drawing lines from endpoint to endpoint.

Step 4. Darken the sides and weld lines of the reducer then add the connecting pipe.