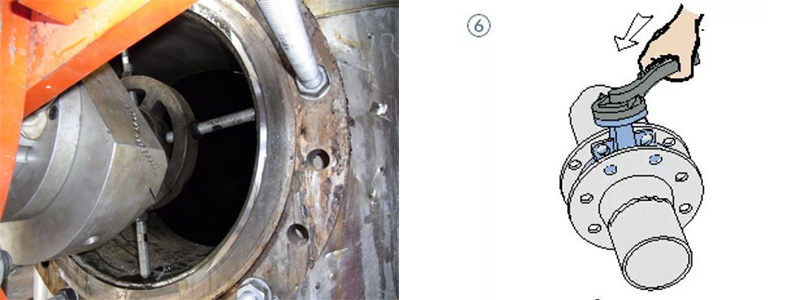

Usually, technicians pay more attention to the leakage between the flange surfaces, and ignore the protection of the fasteners and the outside of the pipe. Insufficient protection of the outside will accelerate and enlarge the damage of the flanges and fasteners, accelerate the deterioration of the entire sealing system, and It may quickly damage the structural integrity of the system and cause seal failure, which may cause extremely serious consequences in a harsh external environment.

The ideal solution should take into account excellent anti-corrosion protection performance and simple construction procedures. It is easy to operate bolts during maintenance and should be suitable for flanges of various sizes and shapes. Common solutions currently on the market include:

Maintenance paint solution

Maintenance paint is usually epoxy or polyurethane coating, which is a hard film that can be directly bonded to the substrate. There are many corners and edges in the flange. Due to the thinning of the edges, it is difficult for the traditional paint system to cover the edges effectively. Although the thickened coating can solve the problem of edge protection, it also seals the fasteners and cannot be removed for subsequent repairs. In addition, the coating will be damaged when the bolts are operated and must be repainted after repairs.

Hot melt plastic solutions

Hot-melt plastics are essentially waxy fusible polymers that are heated at high temperatures and sprayed onto the surface of the substrate through professional hot-melt equipment. The advantage of this protection method is that it can be remelted and reused, thereby saving costs. However, this method also requires hot work, professional equipment and construction services. Although it can be reused, it is not easy to open and seal during maintenance.

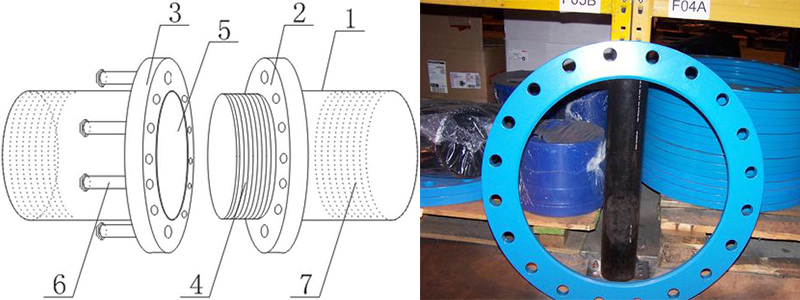

New peelable sealing film system

In order to deal with flange corrosion problems, some companies have used the chemical action of polymers to develop a new type of peelable sealing membrane system that is both strong and flexible enough. It can be peeled off forcefully, but it will not tear, has the elasticity of rubber, and is completely free of isocyanates and toxic metal catalysts.The system is specially designed to provide protection for flanges, fasteners and related pipes. It can be bonded to manually processed substrates without thermal processing, but it makes construction safe and simple.

The system uses corrosion inhibitors as primers to provide comprehensive corrosion protection. At the same time, the coating itself has strong adhesion, which can remove all moisture in the system.

Although there are different solutions to the flange anti-corrosion problem on the market, most of the solutions do not have excellent anti-corrosion performance at the same time, suitable for various flange sizes and shapes, easy to install, and easy to maintain. However, the new peelable sealing membrane system has undergone precise research and development. This solution can provide comprehensive protection for the flange, thereby avoiding the potential risk of flange leakage.