Different slip on flange vs socket weld flange in using:

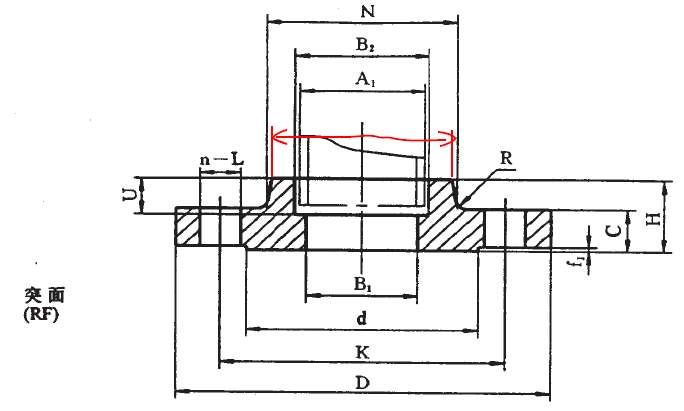

The connection between the slip on flange and the pipe is to first insert the pipe into the flange inner hole to an appropriate position, and then lap welding. The advantage is that the flat welding flange is easier to align when welding and assembly, and the price is cheap, so the flat welding flange Has been widely used. The internal pressure calculation of the strength of the flat welding flange is about two thirds of the corresponding butt welding flange. Therefore, the flat welding flange is only suitable for pipeline systems with relatively low pressure levels and no severe pressure fluctuations, vibrations and vibrations. The flat welding flange can be subdivided into two types: flat welding flange with neck and flat welding flange.

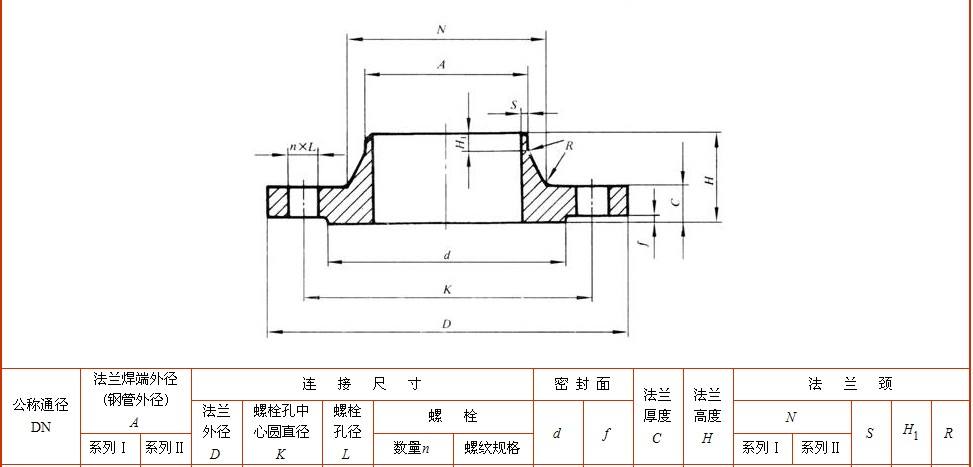

The basic shape of the socket weld flange is the same as the flat welding flange with a neck. A socket hole is opened in the inner hole of the flange. The pipe is inserted into the socket hole and welded. There is a gap between the flange and steel pipe, which is prone to corrosion. If a weld is made in the inside, this corrosion can be avoided. Socket flanges welded on the inner and outer sides have a fatigue strength 5% greater than flat welded flanges and the same static strength. When using this socket flange, its inner diameter must be the same as the inner diameter of the pipe. The socket flange is only suitable for pipes with a nominal diameter below 80.