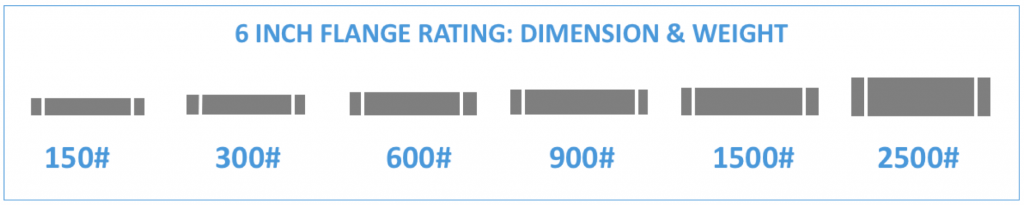

Flange pressure rating description (and chart)

What is the ANSI flange pressure rating? How to choose the right flange grade?"Flange rating" refers to the maximum pressure (in psi or bar) that the flange is subjected to at elevated temperatures. Flanges with higher ratings (grades) are stronger than flanges with lower ratings because they withstand greater pressure when the temperature rises. Flange made from different materials show different pressure-temperature performance at the same rating. In this article, you can find pressure rating charts for carbon, alloy, and stainless steel flanges, as well as some guidance on choosing the right ratings for piping applications.

ANSI flange pressure rating description:

According to ANSI / ASME B16.5 specifications, there are seven flange pressure levels: 150, 300, 400, 600, 900, 1500, and 2500.

Now, let’s look at what this means in terms of pressure rating:

the class 150 flange withstands just 140 psi at a temperature of 600 degrees F° (as per the rating chart below)

the class 300 flange (bigger and stronger, but with the same bore size) withstands 570 psi at the same temperature of 600 degrees F°

finally, a class 2500 flange of the same size bears 34 times more pressure than the class 150 rated flange, reaching a whopping 4730 psi rating at 600 F°!

So, how to select the proper flange rating?

Find the rating table that applies to your flange scrolling below (this depends on the material of the flange, as flanges with different material grades have different pressure ratings)

Determine the max working temperature in your piping system (i.e. select one line in the table)

Select a rating based on the maximum pressure you expect at that temperature level (i.e. select one column in that line)

you have the required rating!

To help you do this easily, find below the ASME B16.34 pressure rating charts for the most common flange materials (carbon, alloy, stainless).

ANSI slip on flange pressure ratings

Welding neck flange pressure ratings

| ANSI/ASME B16.34 | ANSI PRESSURE RATING | ||||||

| Temperature (in F°) | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| < 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| Hydrostatic Test Pressure (in Psig) | 450 | 1125 | 1500 | 2225 | 3350 | 5575 | 9275 |

socket weld neck flange pressure ratings