line pipe X52NS PSL2 NACE MR 0175

What is line pipe X52NS PSL2 NACE MR 0175?Line pipe steel belongs to low carbon and lowcarbonmicroalloyed steel, which is a kind of steel pipe with high technology content and high value. Line pipe is specially applied to oil and natural gas transportation pipe system.

Line pipe X52NS PSL2 NACE MR 0175 is one type of linepipespecially used for sour service. X52 means the steel number PSL2 means the steel grade, “N” means normalizing “S” means for sour service. Certainly these requirement must be under API 5L standard. Generally line pipe X52 with “NS” means the pipe is seamless.

What is the difference between line pipe X52NS PSL2 and normal line pipe X52 PSL2?

X52 is one steel grade of line pipe. It has several types according to serve different environments and two steel levels PSL1 and PSL2. Commonly line pipe with PSL1 is lower requirement than PSL2. X52 PSL2 is just usedfornormal environment and X52NS PSL2 specially for sour service. The main difference between X52 and X52NS refers to chemical component and CVN impact test.

Generally PSL1 no request for CVN impact test and PSL2 must be passed CVN.

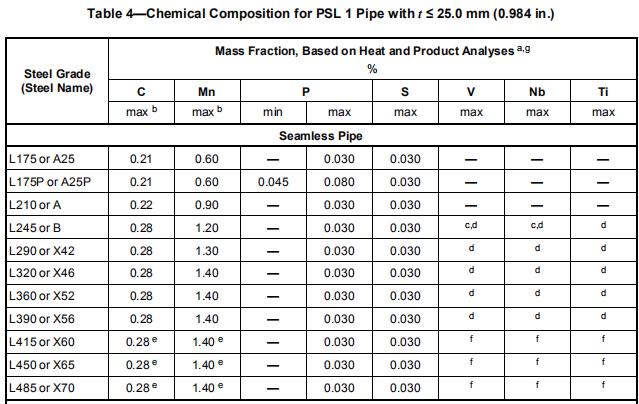

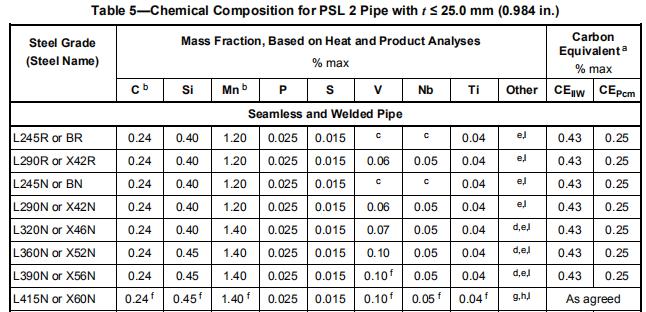

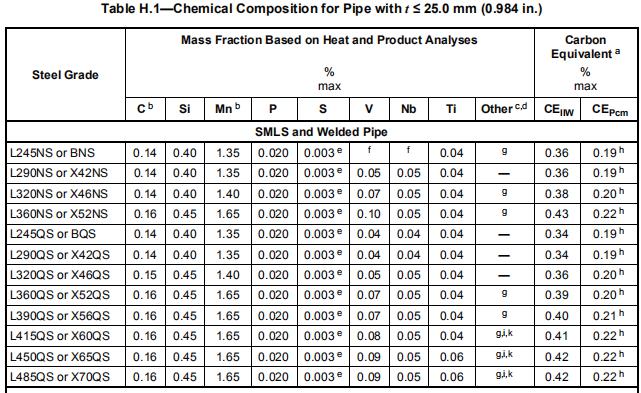

Please see the below tables about chemical component:

What is the NACE MR0175?

NACE was founded in 1943 as the national association of corrosion engineers. The founder is 11 pipeline industrycorrosionengineer.

By far, NACE has become the largest organization to broadcast anti-corrosion knowledge and improve anti-corrosion skills.

In the NACE standard, MR0175 is the material requirement standard for oil and gas production and equipment containing hydrogen sulfide.

Therefore, Nace pipe is used for H2S transportation containing gas and oil, which also means MR0175 sour.

What is the requirement of MR0175?

1.Steel pipes made of NACE material (NACE MR 0175 or ISO 15156).We call it NACE pipes. Therefore, these products are specifically designed for use in oil and gas environments containing corrosive chemicals such as H2S.

2.Chemical component.

For carbon steel and alloy steel line pipes, NACE MR0175 has limits on sulfur content (S 0.002%), phosphorus content (P 0.020%) and carbon content (C 0.10%).

3.Mechanical Strength

Mechanical properties oftensilestrength, and yield strength is same for both PSL1 and PSL2.

4.The material is used in aqueous liquids and media, including various gases or crude oil containing hydrogen sulfide. The absolute partial pressure of H2S is 0.0003Mpa (0.05psia).

5.On the other hand, under these conditions, it does not need to be applied to MR0175. It depends on the user.

6.A.Low pressure gas: the total pressure is less than 0.4mpa (65psia).

7.Bay low pressure gas-oil multiphase media: total depression at 1.83 MPa.

8.MR0175 standard for general materials requires selection of anti-cracking materials, anti-cracking carbon and low alloy steel, cast iron, anti-crackingalloysand other alloys.And specify the requirements for H2S containing devices.

Previous:3PE anti-corrosion steel pipe spray mark

Next:What are the details to be aware of when buying stainless steel elbows?

Next:What are the details to be aware of when buying stainless steel elbows?