Points for attention in slip on flange

When using slip on flange, we may overlook some of the specifications used, so what should we pay attention to when using slip on flange?

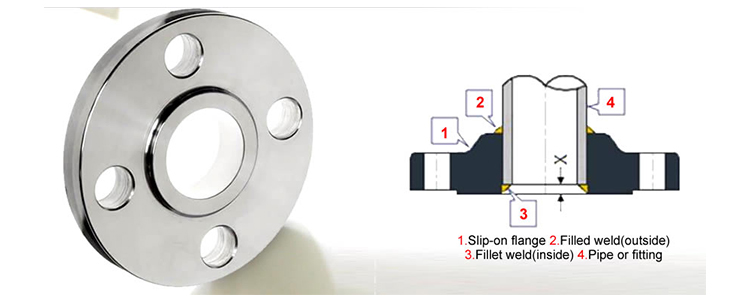

Here are some features of slip-on flanges:

Ease of Installation: Slip-on flanges are relatively easy to install since they can be easily slipped over the pipe end and then welded in place. This makes them a popular choice for applications where frequent disassembly and reassembly are not required.Welding: Slip-on flanges have a circular weld groove on the inside, which allows for proper welding to the pipe. The pipe is typically inserted into the flange before welding, creating a strong and secure joint.

Low Cost: Slip-on flanges are generally more cost-effective compared to other types of flanges because of their simpler design and ease of installation.

Pressure Rating: Slip-on flanges come in various pressure ratings to match the requirements of the piping system. They can handle a range of pressures depending on the material and design specifications.

Applications: These flanges are commonly used in applications with lower pressure and temperature requirements, such as water supply, wastewater treatment, and some industrial processes.

Points for attention in slip on flange

1. In order to prevent the corrosion between the eyes caused by the heating of the flange cover, the welding current should not be too large, less than 20% than the carbon steel electrode, the arc should not be too long, and the layers should be cooled quickly, so the narrow bead should be preferred.2. The electrode should be kept dry when used. The titanium-calcium type should be kept dry at 150 C for 1 hour, and the low a hydrogen type should be kept dry at 200-250 C for 1 hour, so as to prevent sticky oil and other dirt on the electrode coating, so as to avoid increasing the carbon content in the welding seam and affecting the quality of the welding parts.

3. When flat welded flange pipe fittings are welded, carbides are precipitated by repeated heating, which reduces corrosion resistance and mechanical properties of the products.

4. The hardened flange of chrome slip on flange pipe is larger after welding and the flange is easy to crack. If the same type of chromium stainless steel electrode (G202, G207) is used for welding, it is necessary to preheat above 300 C and slow cooling treatment around 700 C after welding. If the weldment can not be heat treated after welding, plain welding flange pipe electrode (A107, A207) shall be selected.

5, slip on flange, in order to improve corrosion resistance and weldability and increase appropriate amount of stable elements Ti, Nb, Mo, etc., weldability is better than chromium flat welded flange. When using the same type of chromium flat welding flange electrode (G302, G307), it should be preheated above 200 C and tempered around 800 C after welding. If the weldments are not heat treated, plain welding flange pipe electrodes (A107, A207) shall be selected.

Previous:Production of pipeline steel alloy pipe fittings and application of carbon steel pipe fittings

Next:Some knowledge about steel pipe elbows

Next:Some knowledge about steel pipe elbows