Features of slip on flange

slip on flange on this issue has been a relatively concerned topic, it is related to the cost of production and economic benefits of companies and enterprises, so the sealing principle of flange is constantly improving and improving.

However, the main design drawback of slip on flange is that it can not guarantee no leakage. This is the shortcoming of its design: the connection is dynamic, and such as thermal expansion and fluctuating periodic load will cause the movement between the flange surface, affecting the function of the flange, so that the integrity of the flange is damaged, eventually leading to leakage. Any product can not be defective, but try to control the insufficiency of the product to a minimum, so the company in the production of flat welded flange as far as possible to improve the performance of the product, so that it plays a maximum role.

slip on flange features: slip on flange not only saves space and reduces weight, more importantly, to ensure that the joint will not leak, has good sealing performance.

However, the main design drawback of slip on flange is that it can not guarantee no leakage. This is the shortcoming of its design: the connection is dynamic, and such as thermal expansion and fluctuating periodic load will cause the movement between the flange surface, affecting the function of the flange, so that the integrity of the flange is damaged, eventually leading to leakage. Any product can not be defective, but try to control the insufficiency of the product to a minimum, so the company in the production of flat welded flange as far as possible to improve the performance of the product, so that it plays a maximum role.

slip on flange features: slip on flange not only saves space and reduces weight, more importantly, to ensure that the joint will not leak, has good sealing performance.

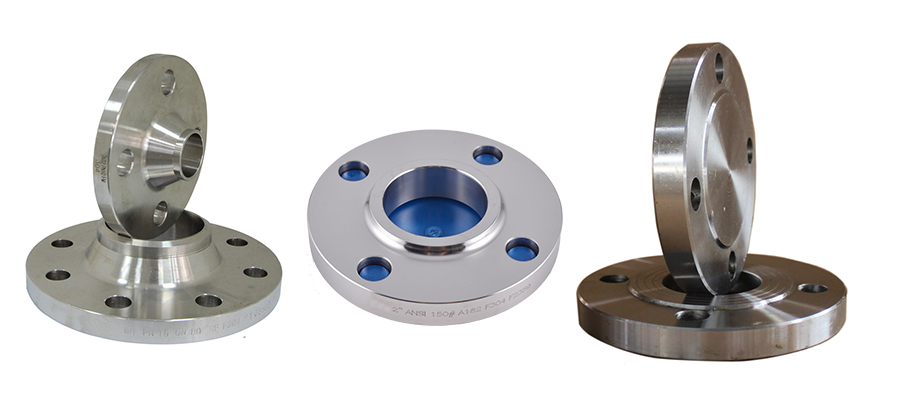

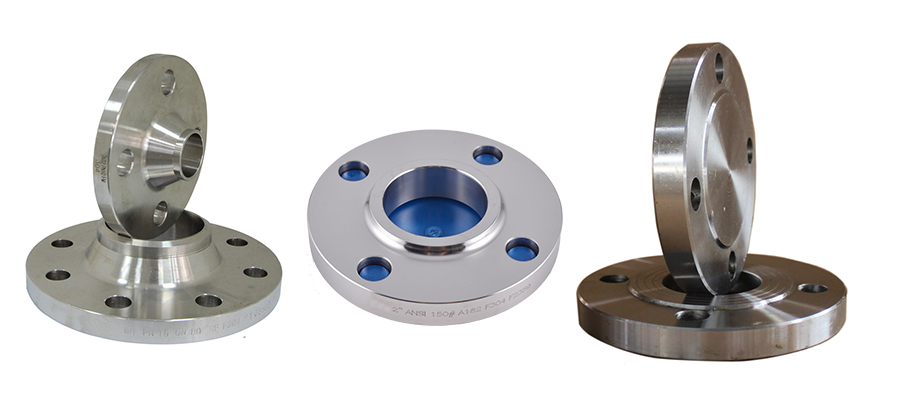

Design: Slip-on flanges have a circular shape with a flat sealing surface and a protruding hub. The flange slips over the pipe, hence the name "slip-on," and is then welded to provide a secure connection.

Easy Installation: Slip-on flanges are relatively easy to install compared to other types of flanges. The flange slides onto the pipe, allowing for quick alignment and welding of the flange to the pipe.

Lower Cost: Slip-on flanges are often less expensive compared to other types of flanges, such as weld neck or socket weld flanges. This makes them a cost-effective choice for applications where frequent disassembly is not required.

Applicable in Low-Pressure Systems: Slip-on flanges are suitable for low-pressure systems or applications where the stress levels and flow rates are relatively low. They are commonly used in water supply systems, plumbing, and some industrial applications.

Alignment Flexibility: Slip-on flanges offer some flexibility in pipe alignment during installation. The slip-on design allows for slight movement and rotation of the flange on the pipe, making it easier to achieve proper alignment during welding.

Limited Pressure and Temperature Ratings: Slip-on flanges are not suitable for high-pressure or high-temperature applications, as their design does not provide the same level of strength and sealing as some other flange types.

Variety of Materials: Slip-on flanges are available in various materials to suit different applications and media. Common materials include carbon steel, stainless steel, alloy steel, and non-metallic materials like PVC or CPVC.

Wide Range of Sizes: Slip-on flanges come in a wide range of sizes to accommodate different pipe diameters and system requirements.

The size of the compact flange is reduced by reducing the diameter of the seal, which will reduce the cross-section of the seal surface. Second, the flange gasket has been replaced by the sealing ring to ensure that the seal faces the matching of the sealing surface. As a result, only a small amount of pressure is needed to compress the sealing surface. As the required pressure decreases, the size and number of bolts can be reduced accordingly, so a new product with small volume and light weight (70% - 80% less weight than the traditional flange) is finally designed. Therefore, slip on flange is a kind of high quality flange products, which reduces the quality and space, and plays an important role in industrial applications.

Previous:What is the difference between straight steel pipe and spiral steel pipe?

Next:Forming steps of stamping elbow

Next:Forming steps of stamping elbow