Customized products

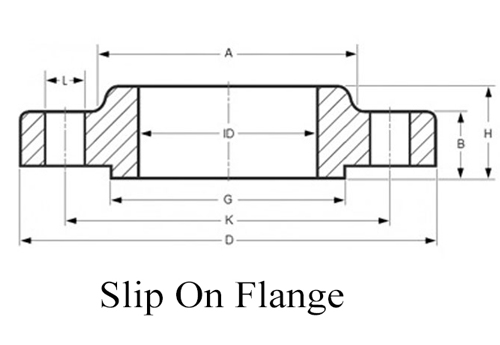

Slip on Pipe Flanges

SPECIFICATIONS

Slip on Pipe Flanges

Slip on Pipe Flanges are easy to draw, easy to manufacture, low cost, widely used, but poor rigidity, so it must not be used in the chemical process piping system with supply and demand, flammable, explosive and high vacuum requirements, and high and extremely hazardous occasions. The sealing type has plane and protrusion surface.

We has some different standard slip on flanges:

ASME Carbon Slip On Flange Class 150

Characteristics of Slip on Pipe Flanges:

Slip on Pipe Flanges not only saves space, reduces the weight, but also ensures that the joints will not leak, with good sealing performance. The reduced size of the compact flange is due to a reduction in the diameter of the seal, which reduces the cross-section of the sealing surface. Secondly, the flange gasket has been replaced by the sealing ring to ensure the sealing face matching. As a result, it only takes a little pressure to press the cover tightly. With the reduction of the required pressure, the size and quantity of bolts can be reduced correspondingly, so a new product with small size and lighter weight (less weight 70%~80% than traditional flange) is designed. Therefore, the flat welding flange type of a relatively high-quality flange products, reduce the quality and space, the industrial use played an important role.

Application of of Slip on Pipe Flanges:

Compared with the welding neck flange, the slip on pipe flanges are simple in structure and used in timber, but the rigidity and sealing are inferior to those with welding neck flange. The slip on pipe flanges are widely used in the connection of medium and low pressure vessels and pipelines. The slip on pipe flanges of the vessel can be divided into type A and B. A slip on pipe flanges structure are a common ring plate. B-type slip on pipe flanges except ring plate with a short and thick tube section, after welding the sealing surface, and the method Lan in conjunction with the short section of the ladder-shaped groove (equivalent to socket welding flange), to ensure the quality of welding, so good sealing performance, used for high sealing requirements of the occasion, design in accordance with the overall type of flange check.

The slip on vision mirror is one of the main accessories of industrial equipment installation, in the oil, chemical, mechanical, pharmaceutical, food and other industrial production equipment containers, the mirror can be observed at any time in the container liquid, gas, steam and other media flow and reaction, to monitor production, avoid the production process of the role of accidents.