What are the differences between socket weld flange and weld neck flange?

What are the differences between socket weld flange and weld neck flange?

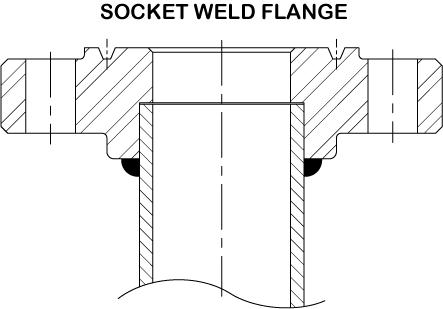

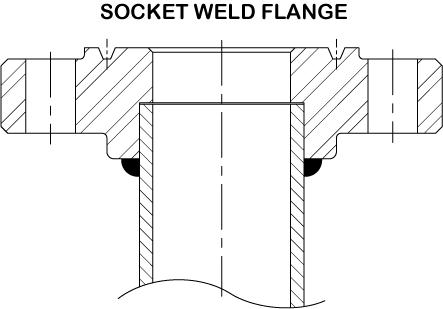

First, the shape between socket weld flange and weld neck flange is different.

In general, the socket weld flange has a short neck, which has a large enough hole to slide through the end of the pipe. Pipe to the shoulder left in the flange hole, about an inch inside the flange face, from the flange neck to the pipe of the fillet weld fixed and sealed connection. Usually, the socket weld flange is not welded in the flange of the pipe and the shoulder.

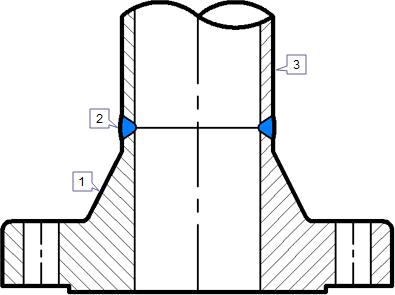

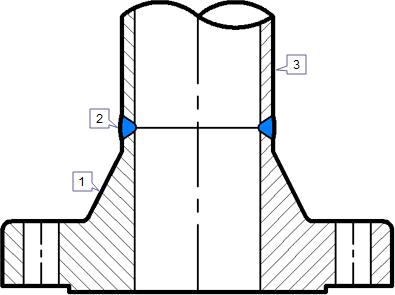

Weld neck flange has a long conical hub, often used in high pressure applications. The sealing surface of the welding neck flange is RF (raised face), FF(flat face) and ring joint (RTJ). It is very important to specify the planned pipeline that is being used when ordering the weld neck flange. This is because the inner diameter of the flange matches the inner diameter of the pipe. This flanged joint with the pipe joint with the tapered hub makes the flange very resistant to sag and very strong connections. These flanges are suitable for extreme temperature fluctuations and may have a large number of bending and processing flanges.

Second, The application ranges of socket weld flange and weld neck flange are different.

Welding neck flange is not easy to deformation, good sealing, wide application, have corresponding rigid and elastic demand and reasonable butt thinning transition, joint good distance away from the joint face the faying surface from welding deformation temperature, it take more complex syndromes beep form structure, suitable for pressure or temperature fluctuations of pipeline or high temperature, high pressure and low temperature pipes, commonly used in PN is greater than 2.5 MPa pipe and valve connection; It is also used to transport expensive, inflammable and explosive medium.

Sealing surface of socket weld flange : raised face surface (RF), Male Female surface (MFM), tenon groove surface (TG), ring joint surface (RJ)

Application scope of socket weld flange: boiler pressure vessel, petroleum, chemical industry, shipbuilding, pharmaceutical, metallurgy, machinery, stamping elbow food and other industries. It is often used in pipelines with PN less than or equal to 10.0MPa and DN less than 40.

First, the shape between socket weld flange and weld neck flange is different.

In general, the socket weld flange has a short neck, which has a large enough hole to slide through the end of the pipe. Pipe to the shoulder left in the flange hole, about an inch inside the flange face, from the flange neck to the pipe of the fillet weld fixed and sealed connection. Usually, the socket weld flange is not welded in the flange of the pipe and the shoulder.

Weld neck flange has a long conical hub, often used in high pressure applications. The sealing surface of the welding neck flange is RF (raised face), FF(flat face) and ring joint (RTJ). It is very important to specify the planned pipeline that is being used when ordering the weld neck flange. This is because the inner diameter of the flange matches the inner diameter of the pipe. This flanged joint with the pipe joint with the tapered hub makes the flange very resistant to sag and very strong connections. These flanges are suitable for extreme temperature fluctuations and may have a large number of bending and processing flanges.

Second, The application ranges of socket weld flange and weld neck flange are different.

Welding neck flange is not easy to deformation, good sealing, wide application, have corresponding rigid and elastic demand and reasonable butt thinning transition, joint good distance away from the joint face the faying surface from welding deformation temperature, it take more complex syndromes beep form structure, suitable for pressure or temperature fluctuations of pipeline or high temperature, high pressure and low temperature pipes, commonly used in PN is greater than 2.5 MPa pipe and valve connection; It is also used to transport expensive, inflammable and explosive medium.

Sealing surface of socket weld flange : raised face surface (RF), Male Female surface (MFM), tenon groove surface (TG), ring joint surface (RJ)

Application scope of socket weld flange: boiler pressure vessel, petroleum, chemical industry, shipbuilding, pharmaceutical, metallurgy, machinery, stamping elbow food and other industries. It is often used in pipelines with PN less than or equal to 10.0MPa and DN less than 40.