Welding Neck Flange

CLASS 2500 CARBON PIPE WELDED NECK FLANGES

SPECIFICATIONS

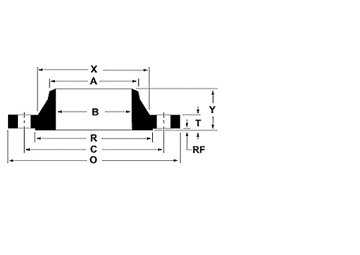

| Nominal Pipe Size |

Outside Diameter |

Thickness | Raised Face Diameter |

Length Thru Hub |

Point of Weld |

Hub Diameter |

Bore | Approximate Weight | Bolt Circle | Number of Holes |

Diameter of Holes |

| (O) | (T) | (R) | (Y) | (A) | (X) | (B) | (lbs) | (C) | |||

| 1/2 |

5.25 | 1.19 | 1.38 | 2.88 | 0.84 | 1.69 | Specified by purchaser |

7 | 3.5 | 4 | 0.88 |

| 3/4 | 5.5 | 1.25 | 1.69 | 3.13 | 1.05 | 2 | Specified by purchaser |

8 | 3.75 | 4 | 0.88 |

| 1 | 6.25 | 1.38 | 2 | 3.5 | 1.32 | 2.25 | Specified by purchaser |

12 | 4.25 | 4 | 1 |

| 1 1/4 | 7.25 | 1.5 | 2.5 | 3.75 | 1.66 | 2.88 | Specified by purchaser |

17 | 5.13 | 4 | 1.13 |

| 1 1/2 | 8 | 1.75 | 2.88 | 4.38 | 1.9 | 3.13 | Specified by purchaser |

25 | 5.75 | 4 | 1.25 |

| 2 | 9.25 | 2 | 3.63 | 5 | 2.38 | 3.75 | Specified by purchaser |

42 | 6.75 | 8 | 1.13 |

| 2 1/2 | 10.5 | 2.25 | 4.13 | 5.63 | 2.88 | 4.5 | Specified by purchaser |

52 | 7.75 | 8 | 1.25 |

| 3 | 12 | 2.63 | 5 | 6.63 | 3.5 | 5.25 | Specified by purchaser |

94 | 9 | 8 | 1.38 |

| 4 | 14 | 3 | 6.19 | 7.5 | 4.5 | 6.5 | Specified by purchaser |

145 | 10.75 | 8 | 1.63 |

| 5 | 16.5 | 3.63 | 7.31 | 9 | 5.56 | 8 | Specified by purchaser |

245 | 12.75 | 8 | 1.88 |

| 6 | 19 | 4.25 | 8.5 | 10.75 | 6.63 | 9.25 | Specified by purchaser |

380 | 14.5 | 8 | 2.13 |

| 8 | 21.75 | 5 | 10.63 | 12.5 | 8.63 | 12 | Specified by purchaser |

580 | 17.25 | 12 | 2.13 |

| 10 | 26.5 | 6.5 | 12.75 | 16.5 | 10.75 | 14.75 | Specified by purchaser |

1075 | 21.25 | 12 | 2.63 |

| 12 | 30 | 7.25 | 15 | 18.25 | 12.75 | 17.38 | Specified by purchaser |

1525 | 24.38 | 12 | 2.88 |

Product Name:CLASS 2500 CARBON PIPE WELDED NECK FLANGES

Type: welding neck

Material: carbon stell

Size: 1/2” to 24” or as per customer’s request.

Origin: China

Brand: Metleader

Packaging: plywood case or pallet

Inspection: inspection inside or the third party

Lead time: 30days

Surface: black painting, anti-rust oil and varnish.

Pipe flanges that are made to standards of ASME/ANSI B16.5 or ASME B16.47 are typically made from forged materials ASTM A105 and have machined surfaces. ANSI B16.5 is about the size from 1/2inch to 24inch and ANSI B16.47 refer to 26in to 60inch. The pressure class of ANSI B16.5 involves to class150, 300, 600, 900, 1500, 2500 and ASME B16.47 involves to class75, 150, 300, 400, 600, 900.

CLASS 2500 CARBON PIPE WELDED NECK FLANGES is just produce according to standard of ASME/ANSI B16.5. The raw material is ASTM A105, the sealing surface includes RF and RTG because of the high pressure. Welding neck flange is not easy to be deformed, good sealing, widely used. There is a corresponding rigidity and elasticity requirements and reasonable butt welding thinning transition, the welding distance from the joint surface, the joint surface from the welding temperature deformation.

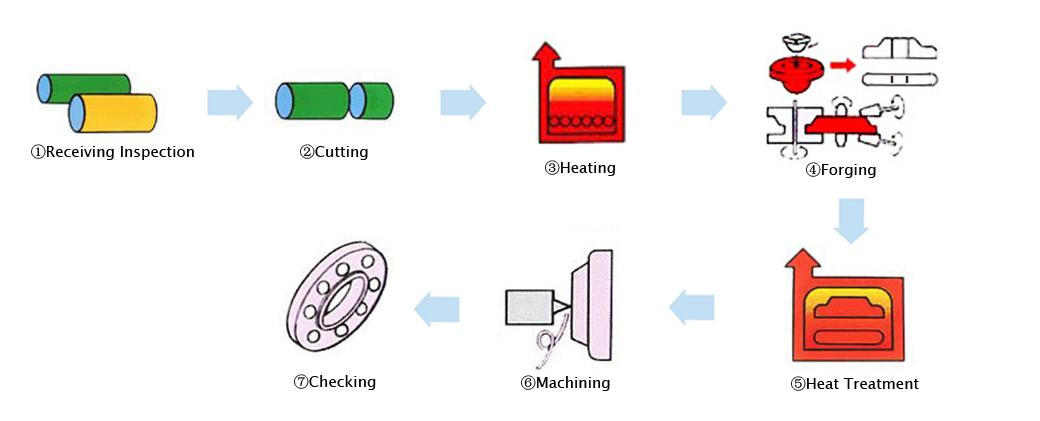

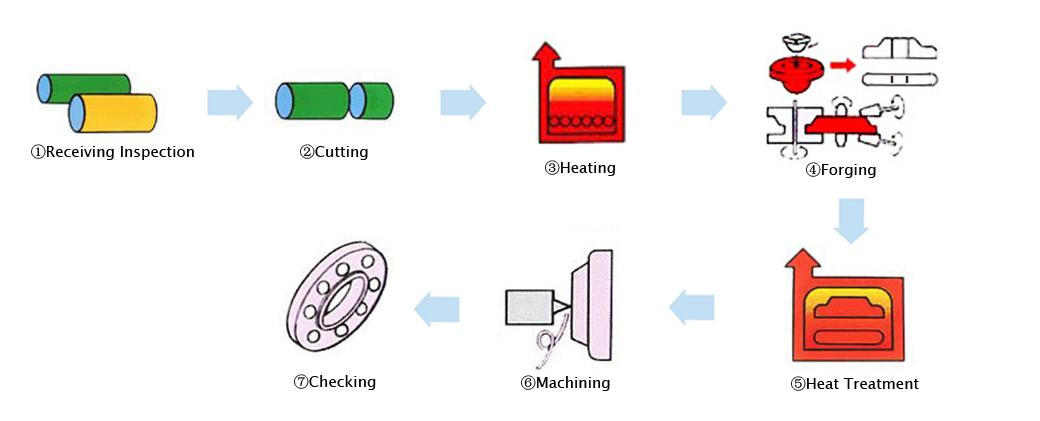

The production processing of welding neck flange:

Forging processing is the common production method of steel pipe flanges. It refer to the following steps, the selection of high-quality billet blanking, heating, forming, and cooling after forging. Forging process methods are forged, die forging and membrane forging. Production, according to the size of the forging quality, the number of production batch selection of different forging methods.

Type: welding neck

Material: carbon stell

Size: 1/2” to 24” or as per customer’s request.

Origin: China

Brand: Metleader

Packaging: plywood case or pallet

Inspection: inspection inside or the third party

Lead time: 30days

Surface: black painting, anti-rust oil and varnish.

Pipe flanges that are made to standards of ASME/ANSI B16.5 or ASME B16.47 are typically made from forged materials ASTM A105 and have machined surfaces. ANSI B16.5 is about the size from 1/2inch to 24inch and ANSI B16.47 refer to 26in to 60inch. The pressure class of ANSI B16.5 involves to class150, 300, 600, 900, 1500, 2500 and ASME B16.47 involves to class75, 150, 300, 400, 600, 900.

CLASS 2500 CARBON PIPE WELDED NECK FLANGES is just produce according to standard of ASME/ANSI B16.5. The raw material is ASTM A105, the sealing surface includes RF and RTG because of the high pressure. Welding neck flange is not easy to be deformed, good sealing, widely used. There is a corresponding rigidity and elasticity requirements and reasonable butt welding thinning transition, the welding distance from the joint surface, the joint surface from the welding temperature deformation.

The production processing of welding neck flange:

Forging processing is the common production method of steel pipe flanges. It refer to the following steps, the selection of high-quality billet blanking, heating, forming, and cooling after forging. Forging process methods are forged, die forging and membrane forging. Production, according to the size of the forging quality, the number of production batch selection of different forging methods.